Organic intelligent glass with performance of heat storage and heat release and preparation method thereof

A smart glass and organic technology, applied in the field of organic smart glass and its preparation, can solve problems such as supercooling and phase separation, affecting use, etc., to reduce energy consumption, simple preparation method, easy production and synthesis, and large-scale use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

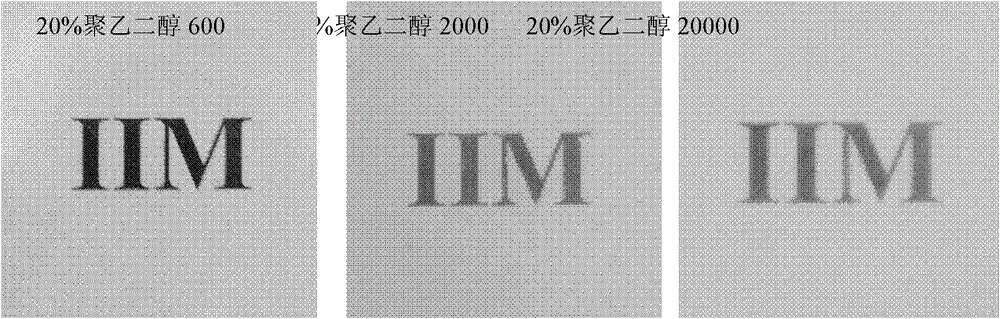

[0029] In this embodiment, the organic smart glass with heat storage and heat release performance is based on polymethyl methacrylate, and polyethylene glycol is an intelligent heat storage and release material. The number average molecular weight of polyethylene glycol is 2000, which is equivalent to The variable temperature is 41-46°C.

[0030] In this embodiment, the organic smart glass with heat storage and heat release properties is prepared as follows:

[0031] Add 25g of newly distilled methyl methacrylate, 2.5g of polyethylene glycol and 25mg of initiator benzoyl peroxide into the conical flask. Wrap a layer of plastic wrap, then tie it tightly with a rubber band, seal it and heat it in a water bath at 70-90°C for pre-polymerization. When the viscosity of the solution system reaches 0.8-1.0 Pa·s, immediately stop heating and cool to room temperature to terminate the polymerization reaction Obtain the prepolymer; pour the obtained prepolymer into the mold, be careful n...

Embodiment 2

[0033] In this embodiment, the organic smart glass with heat storage and heat release performance is based on polymethyl methacrylate, and polyethylene glycol is an intelligent heat storage and release material. The number average molecular weight of polyethylene glycol is 2000, which is equivalent to The variable temperature is 41-46°C.

[0034]In this embodiment, the organic smart glass with heat storage and heat release properties is prepared as follows:

[0035] Add 25g of newly distilled methyl methacrylate, 5g of polyethylene glycol and 5mg of initiator benzoyl peroxide into the conical flask. In order to prevent water vapor from entering the conical flask during prepolymerization, shake well and wrap Put a layer of plastic wrap on it, then tie it tightly with a rubber ring, seal it, and heat it in a water bath at 70-90°C for pre-polymerization. When the viscosity of the solution system reaches 0.8-1.0 Pa·s, immediately stop heating and cool to room temperature to termin...

Embodiment 3

[0037] In this embodiment, the organic smart glass with heat storage and heat release performance is based on polymethyl methacrylate, and polyethylene glycol is an intelligent heat storage and release material. The number average molecular weight of polyethylene glycol is 2000, which is equivalent to The variable temperature is 41-46°C.

[0038] In this embodiment, the organic smart glass with heat storage and heat release properties is prepared as follows:

[0039] Add 25g of newly distilled methyl methacrylate, 7.5g of polyethylene glycol and 10mg of initiator benzoyl peroxide into the conical flask. Wrap a layer of plastic wrap, then tie it tightly with a rubber band, seal it and heat it in a water bath at 70-90°C for pre-polymerization. When the viscosity of the solution system reaches 0.8-1.0 Pa·s, immediately stop heating and cool to room temperature to terminate the polymerization reaction Obtain the prepolymer; pour the obtained prepolymer into the mold, be careful n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com