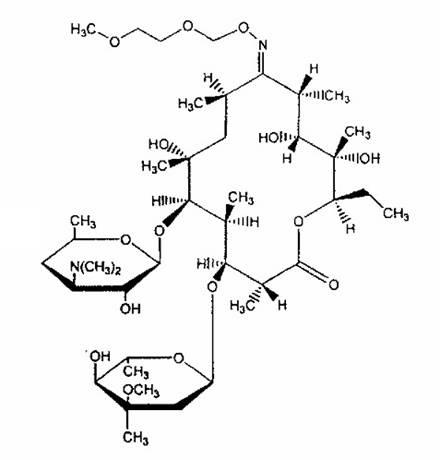

Method for purifying roxithromycin

A roxithromycin, a certain amount of technology, applied in the field of purification technology of roxithromycin, can solve the problems such as the decline of the effect and the difficulty in meeting the production needs, and achieve the effect of good effect, low cost and less three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 15ml of methanol and 15ml of ethanol to 30g of crude roxithromycin as a mixed solvent, mix the three and raise the temperature to 50°C~65°C to dissolve and clarify, then cool slowly, and keep stirring at -5°C after the crystals are precipitated After 3 hours, filter, wash the solid with a small amount of the above mixed solvent at 0-5°C, and dry at 50-55°C to obtain 28.7g of roxithromycin.

[0042] After testing, the HPLC content was 98.26%, impurity A was not detected, impurity B was 0.05%, impurity C was 0.07%, impurity D was 0.03%, impurity E was 0.06%, impurity F was 0.31%, impurity G was 0.04%, impurity H 0.21%, impurity I 0.21%, impurity J 0.15%, impurity K 0.12%. The mass yield is 95.67%.

Embodiment 2

[0044] Add a mixed solution consisting of 150ml methanol and 150ml ethanol to 30g roxithromycin crude product, mix the three to form a mixed system, and raise the temperature to 50°C~65°C to dissolve and clarify, then cool slowly, and wait for the crystals to separate out at -5 Continue to heat and stir for 3 hours at ℃, filter, wash the solid with a small amount of mixed solvent at 0-5 ℃, and dry at 50-55 ℃ to obtain 13.2 g of roxithromycin.

[0045] After testing, the HPLC content was 99.44%, impurity A was not detected, impurity B was 0.03%, impurity C was 0.05%, impurity D was not detected, impurity E was 0.04%, impurity F was 0.05%, impurity G was not detected, Impurity H 0.08%, impurity I 0.08%, impurity J 0.05%, impurity K 0.07%. The mass yield is 44%.

Embodiment 3

[0047] Add a mixed solution consisting of 90ml methanol and 90ml ethanol to 30g crude roxithromycin, mix the three to form a mixed system, and raise the temperature to 50°C~65°C to dissolve and clarify, then cool slowly, and wait for crystals to separate out at -5 Continue to heat and stir for 3 hours at ℃, filter, wash the solid with a small amount of mixed solvent at 0-5 ℃, and dry at 50-55 ℃ to obtain 21.3 g of roxithromycin.

[0048] After testing, the HPLC content was 98.90%, impurity A was not detected, impurity B was 0.05%, impurity C was 0.05%, impurity D was 0.03%, impurity E was 0.02%, impurity F was 0.15%, impurity G was not detected, Impurity H 0.19%, impurity I 0.15%, impurity J 0.11%, impurity K 0.11%. The mass yield is 71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com