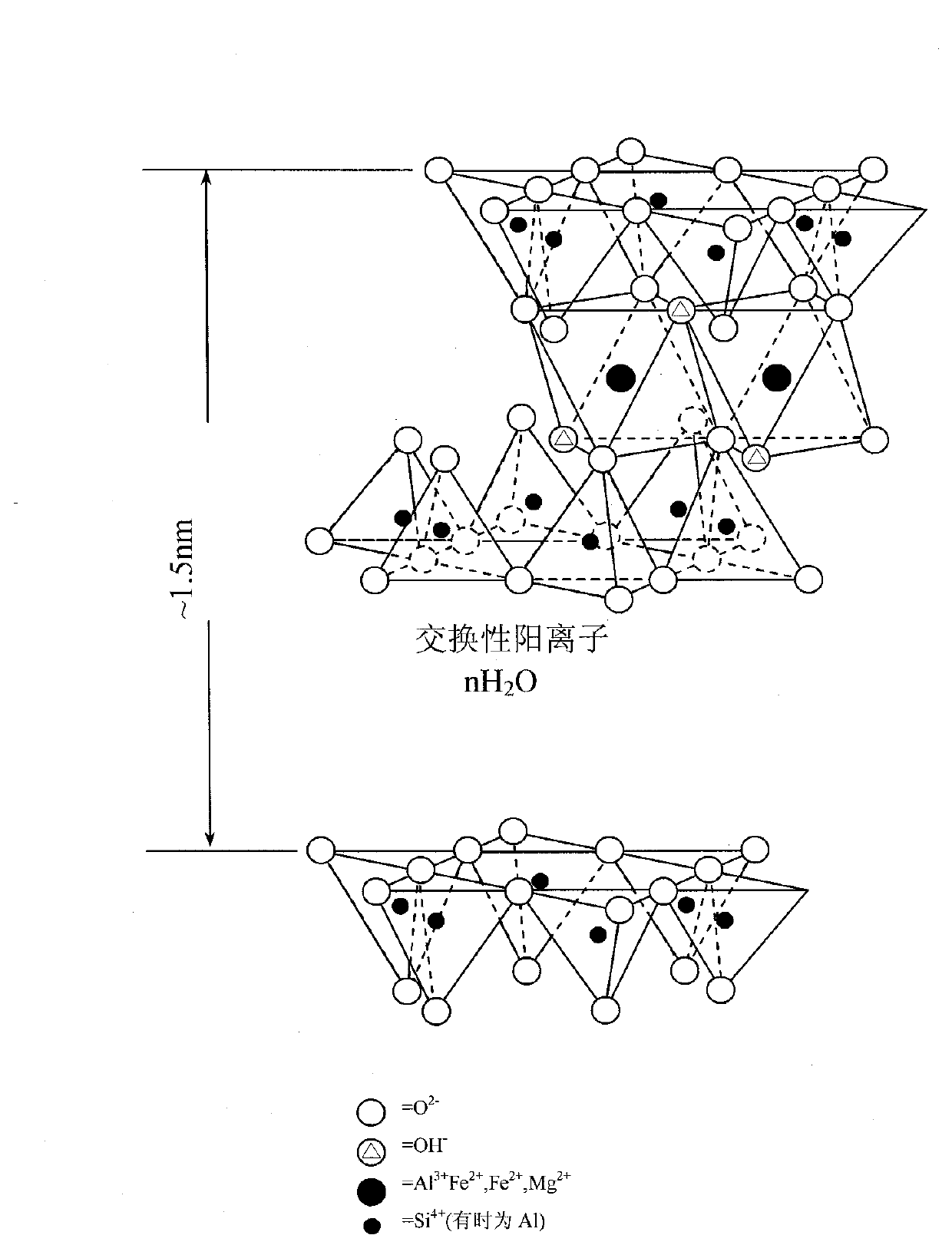

Cationic-nonionic composite organic montmorillonite and preparation method thereof

An organic montmorillonite and non-ionic technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem of organic montmorillonite with strong hydrophilicity and difficulty in separating organic montmorillonite from water phase system, Difficult montmorillonite intercalation modification and other problems, to achieve the effect of easy source, excellent performance and high degree of exfoliation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing cationic-nonionic composite intercalation type organic montmorillonite, the method comprising the following steps:

[0028] A. Purify montmorillonite: purify calcium-based montmorillonite;

[0029] B. Carry out hydration treatment to montmorillonite: the purified calcium-based montmorillonite is made into water suspension, and the hydration treatment is carried out by mixing mechanical stirring and ultrasonic action;

[0030] C. Preparation of cationic-nonionic composite intercalation organic montmorillonite material: record the fully hydrated montmorillonite hydration solution as liquid A, add organic cationic surfactant to liquid A and perform ultrasonic dispersion , followed by mechanical stirring to obtain liquid B, then adding the nonionic surfactant into liquid B and performing ultrasonic dispersion, followed by mechanical stirring, standing at a constant temperature, separating, and drying to obtain a cationic-nonioni...

Embodiment 1

[0069] The purification of embodiment 1 montmorillonite

[0070] ① Pulverize the montmorillonite raw ore with a ball mill and pass through a 200-mesh sieve to obtain montmorillonite powder;

[0071] ② Weigh 80g of montmorillonite powder and dissolve it in 8L of distilled water (packed in a barrel), stir with an electric stirrer for 20 minutes, make the montmorillonite into a suspension with a "concentration" not exceeding 10g / L, and continue to stand at room temperature. Set aside for 8 hours, take out the part with a height <10cm with a siphon;

[0072] ③ Take the upper 10cm suspension, centrifuge, and vacuum dry (70°C) to obtain refined montmorillonite;

[0073] ④ Add distilled water to the remaining part, restore the volume to the original volume, and continue stirring for 20 minutes to disperse the remaining particles larger than 2 μm that have not been "disassembled", and take them out after 8 hours. Repeat this several times until the suspension obtained after adding...

Embodiment 2

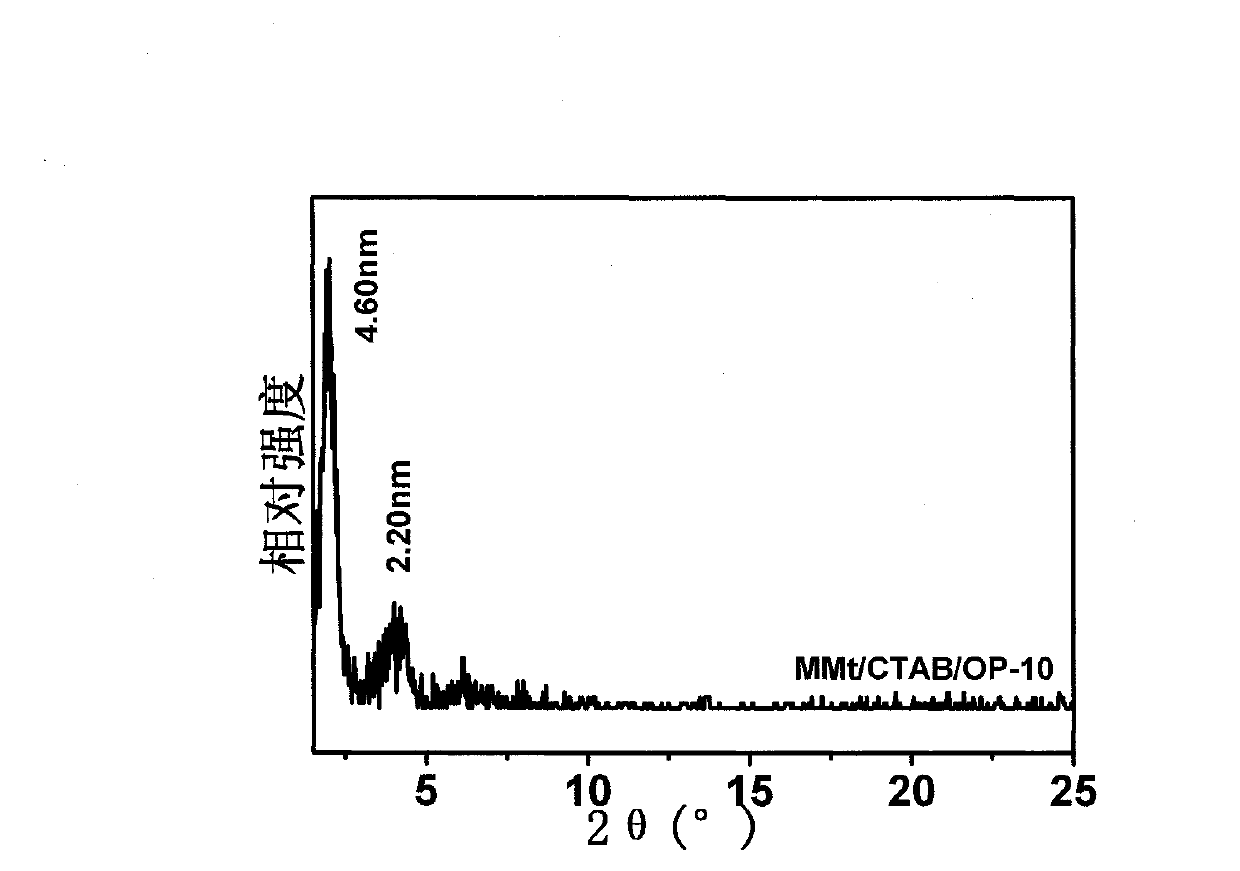

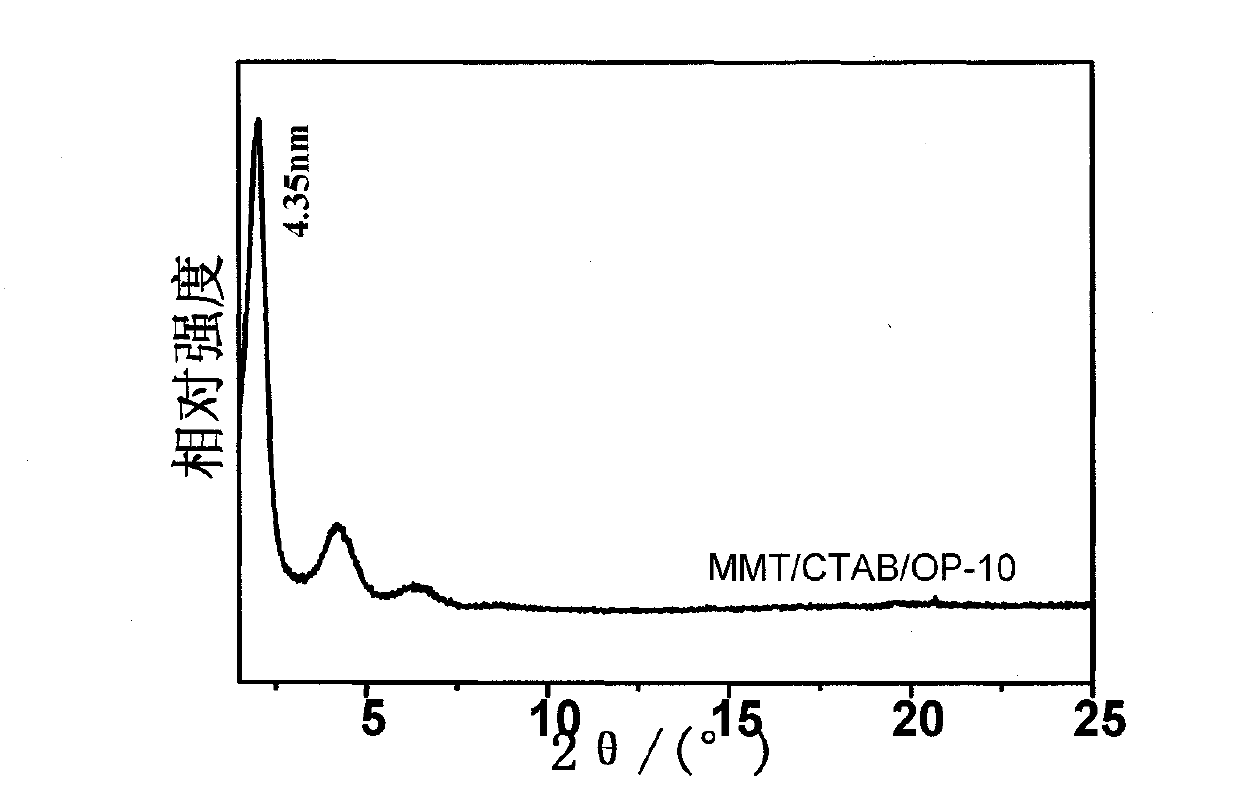

[0074] Example 2 Preparation of cationic-nonionic composite intercalation type organic montmorillonite

[0075] Add 5 g of the montmorillonite obtained in Example 1 with a water-purified cation exchange capacity of 88 meq / 100 g and a particle size of 200 mesh sieve into a three-necked flask filled with 100 ml of water, and hydrate with ultrasonication and mechanical stirring for 1 hour Record it as liquid A, slowly add 0.8g of cetyltrimethylammonium bromide into liquid A, stop ultrasonication after 10 minutes of ultrasonic dispersion, continue mechanical stirring for 0.5-1 hour, add 5g of nonylphenol polyoxyethylene ether (OP-10), after ultrasonic dispersion for 10 minutes, continue mechanical stirring for 1 hour, stop stirring and let stand at constant temperature for 1 hour, cool to room temperature and centrifuge, wash the sample once with deionized water, and dry it in a drying oven at 80°C for several hours, and grind until passing through a 200 mesh sieve to obtain a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com