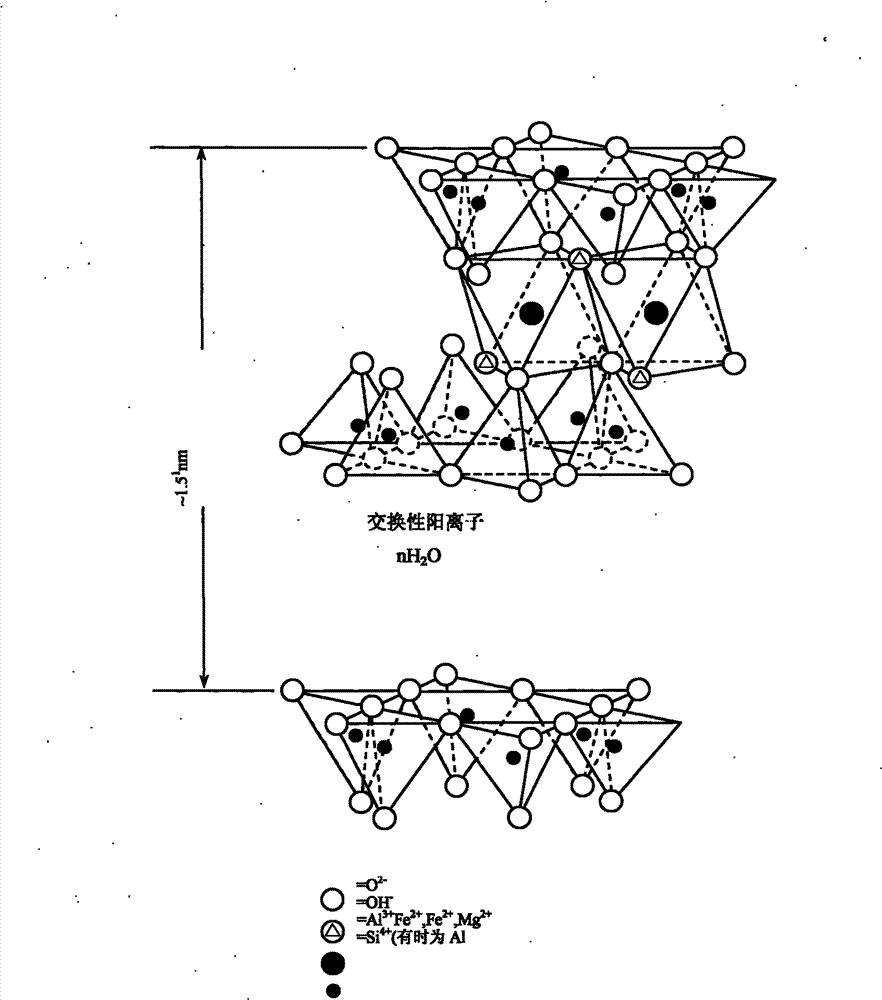

Anionic-cationic composite intercalation type organic montmorillonite material and preparation method thereof

An organic montmorillonite and composite intercalation technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of cumbersome process route, poor product stability, complex preparation process, etc. High stability and high degree of peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of cation-anion composite intercalation type organic montmorillonite, the method comprising the following steps:

[0032] A. Purify montmorillonite: purify natural calcium-based montmorillonite;

[0033] B. Carry out hydration treatment to montmorillonite: the purified montmorillonite is made into water suspension, and the hydration treatment is carried out by mixing with mechanical stirring and ultrasonic action;

[0034] C. Preparation of cation-anion composite intercalation type organic montmorillonite material: record the fully hydrated montmorillonite hydration solution as A liquid, add organic cationic surfactant in A liquid and carry out ultrasonic dispersion, Subsequent mechanical stirring was carried out to obtain liquid B, and then the anionic surfactant was added to liquid B and ultrasonic dispersion was carried out on the machine, followed by mechanical stirring, standing at constant temperature, separation, and dr...

Embodiment 1

[0074] The purification of embodiment 1 montmorillonite

[0075] ① Pulverize the calcium-based montmorillonite raw ore with a ball mill and pass through a 200-mesh sieve to obtain montmorillonite powder;

[0076] ② Weigh 80g of montmorillonite powder and dissolve it in 8L of distilled water (packed in a barrel), stir with an electric stirrer for 20 minutes, make the montmorillonite into a suspension with a "concentration" not exceeding 10g / L, and continue to stand at room temperature. Set aside for 8 hours, take out the part with a height <10cm with a siphon;

[0077] ③ Take the upper 10cm suspension, centrifuge, and vacuum dry (70°C) to obtain refined montmorillonite;

[0078] ④ Add distilled water to the remaining part, restore the volume to the original volume, and continue stirring for 20 minutes to disperse the remaining particles larger than 2 μm that have not been "disassembled", and take them out after 8 hours. Repeat this several times until the suspension obtained ...

Embodiment 2

[0079] Example 2 Preparation of cation-anion composite intercalation type organic montmorillonite

[0080] Add 5 g of calcium-based montmorillonite obtained in Example 1 into a three-necked flask filled with 100 ml of water, and hydrate with ultrasonication and mechanical stirring. 1 hour is recorded as liquid A, slowly add 3g of cetyltrimethylammonium bromide into liquid A, stop ultrasonication after 10 minutes of ultrasonic dispersion, continue mechanical stirring for 2 hours, then add 1.8g of dodecylsulfonic acid Sodium and turn on the ultrasound for 10 minutes, continue mechanical stirring for 1 hour, stop stirring, cool to room temperature and centrifuge, wash the sample once with deionized water, dry it in a drying oven at 80°C for several hours, and grind it to pass through a 200-mesh sieve, that is, A cation-anion composite intercalation type organic montmorillonite was obtained.

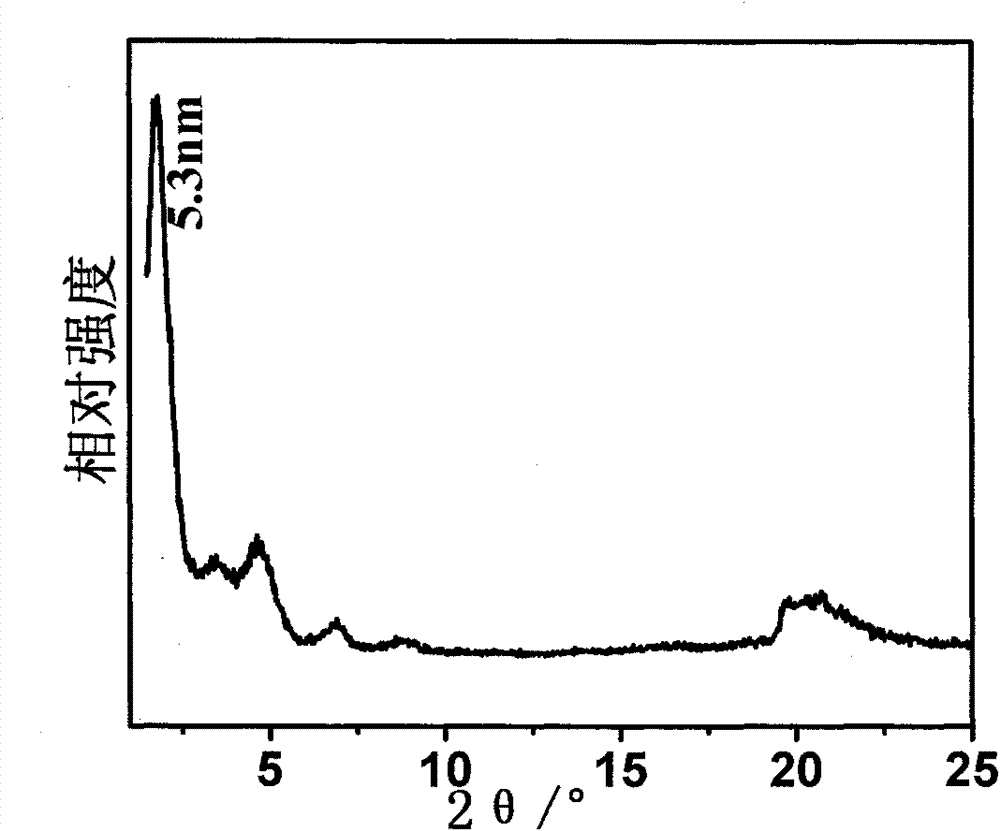

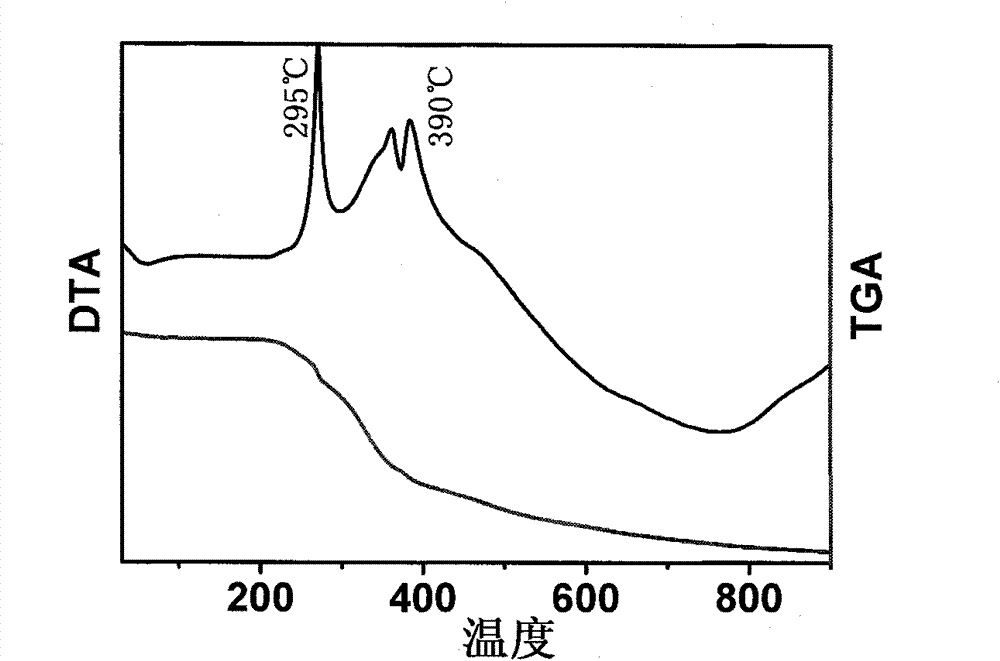

[0081] The X-ray diffraction spectrum (XRD figure) of gained cation-anion compound in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com