Serial-parallel laser process machine

A technology of laser processing and parallel connection, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effects of improved processing range and precision, good stability, and improved working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

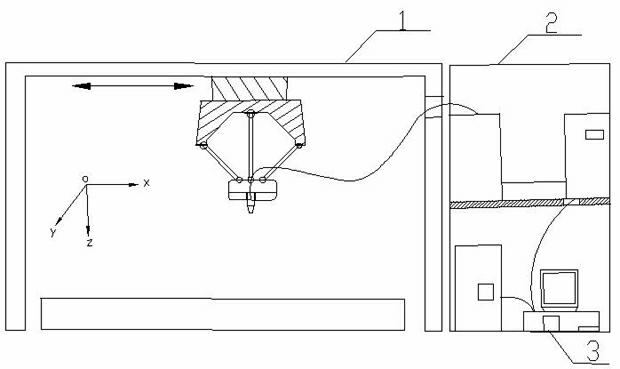

[0017] Laser processing series parallel machine tool of the present invention such as figure 1 Shown: It consists of three parts: serial parallel machine tool 1, laser system 2 and control system 3. Its working principle is that the control system sends out control instructions, one end is sent to the serial-parallel kinematic machine tool, and the other end is sent to the laser system, so that the serial-parallel kinematic machine tool drives the laser head to move according to the instructions, and the laser head is sent by the laser system according to the processing instructions of the control system. Laser pulses .

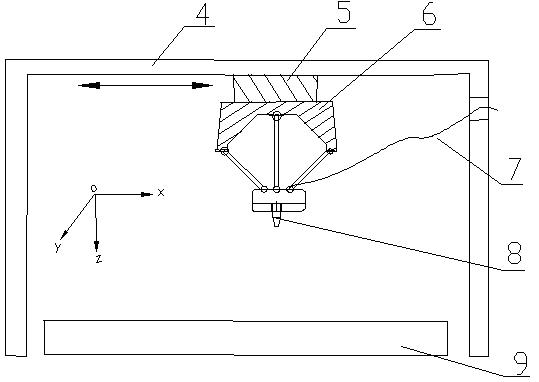

[0018] The serial-parallel kinematic machine tool mechanism of the present invention is as figure 2 Shown: It is composed of bed 4, horizontal guide rail 5, three-degree-of-freedom parallel mechanism 6, optical fiber 7, laser head 8, and workbench 9. The bottom surface of the horizontal guide rail 5 is fixed together with the upper plane of the fixed platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com