Catalyst for reducing CO content in cigarette smoke, and preparation and application thereof

A cigarette smoke and catalyst technology, which is applied in the direction of physical/chemical process catalysts, applications, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems that the taste and aroma of cigarettes cannot be guaranteed, and achieve stable properties and high production efficiency. The effect of simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of transition metal-manganese composite oxide catalyst:

[0035] Add 5mL of concentrated sulfuric acid into 70mL of water and stir well. 4.5 mmol of copper nitrate, 40.5 mmol of manganese sulfate, and 30 mmol of potassium permanganate were added thereto. After stirring evenly, place it in a pressure-resistant reactor, and stand at 120°C for 1 day for crystallization. The reaction mixture was filtered, washed with water, and dried overnight at 110°C. The product is molded into 20-40 mesh particles to obtain the copper-manganese composite oxide catalyst.

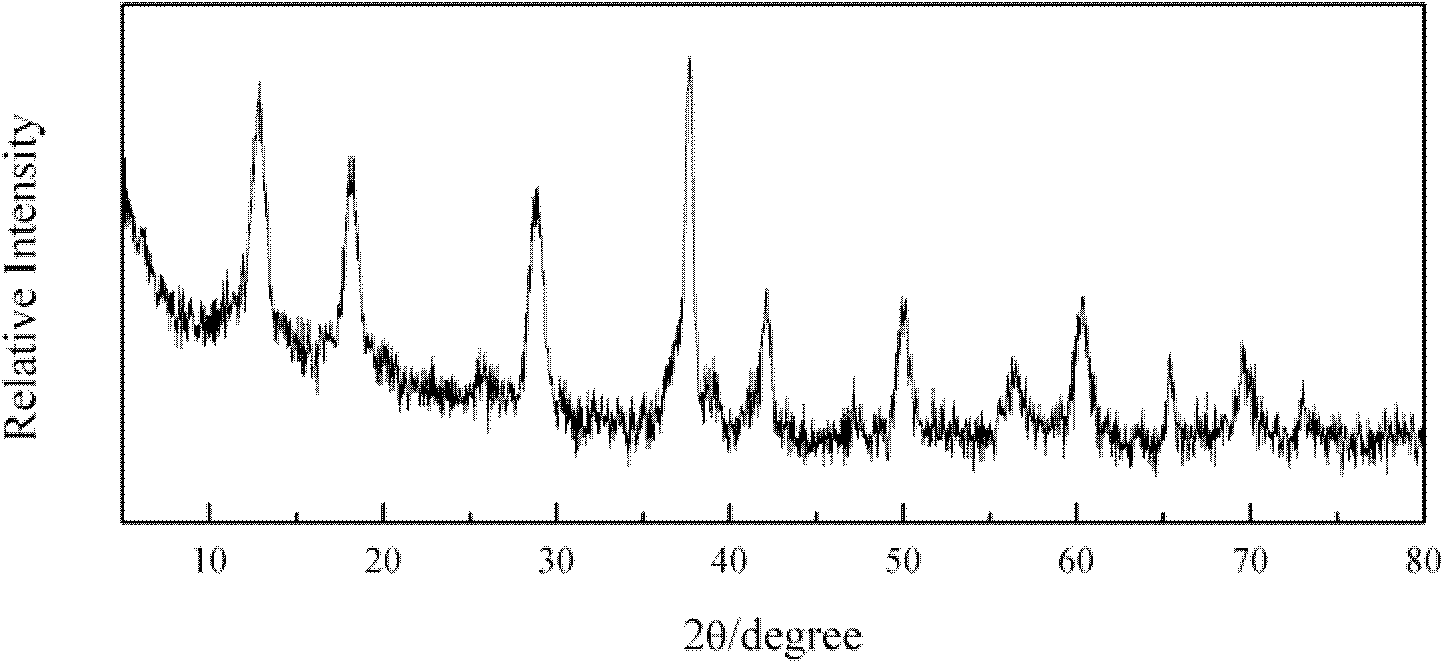

[0036] Obtain the XRD spectrogram of the copper-manganese composite oxide catalyst of the present embodiment through detection, as figure 1 shown, from figure 1 It can be seen that the crystal phase of the copper-manganese composite oxide catalyst in this example is α-MnO 2 Mutually.

Embodiment 2

[0038] Preparation of transition metal-manganese composite oxide catalyst:

[0039] Add 5mL of concentrated sulfuric acid to 75mL of water and stir well. 30.0 mmol of cobalt nitrate, 40.5 mmol of manganese sulfate, and 30 mmol of potassium permanganate were added thereto. After stirring evenly, the temperature of the reaction system was raised to 85° C., and stirring was continued for 3 days. The reaction mixture was filtered, washed with water, and dried overnight at 110°C. The product is molded into 20-40 mesh particles to obtain the cobalt-manganese composite oxide catalyst.

[0040] After detecting the XRD spectrum of the cobalt-manganese composite oxide catalyst of the present embodiment, it can be seen that the crystal phase of the cobalt-manganese composite oxide catalyst of the present embodiment is α-MnO 2 Mutually.

Embodiment 3

[0042] Preparation of transition metal-manganese composite oxide catalyst:

[0043] Add 15mL of concentrated sulfuric acid into 70mL of water and stir well. 7.0 mmol of cerium nitrate, 40.5 mmol of manganese sulfate, and 30 mmol of potassium permanganate were added thereto. After stirring evenly, place it in a pressure-resistant reactor, and stand at 120°C for 3 days for crystallization. The reaction mixture was filtered, washed with water, and dried overnight at 110°C. The product is molded into 20-40 mesh particles to obtain the cerium-manganese composite oxide catalyst.

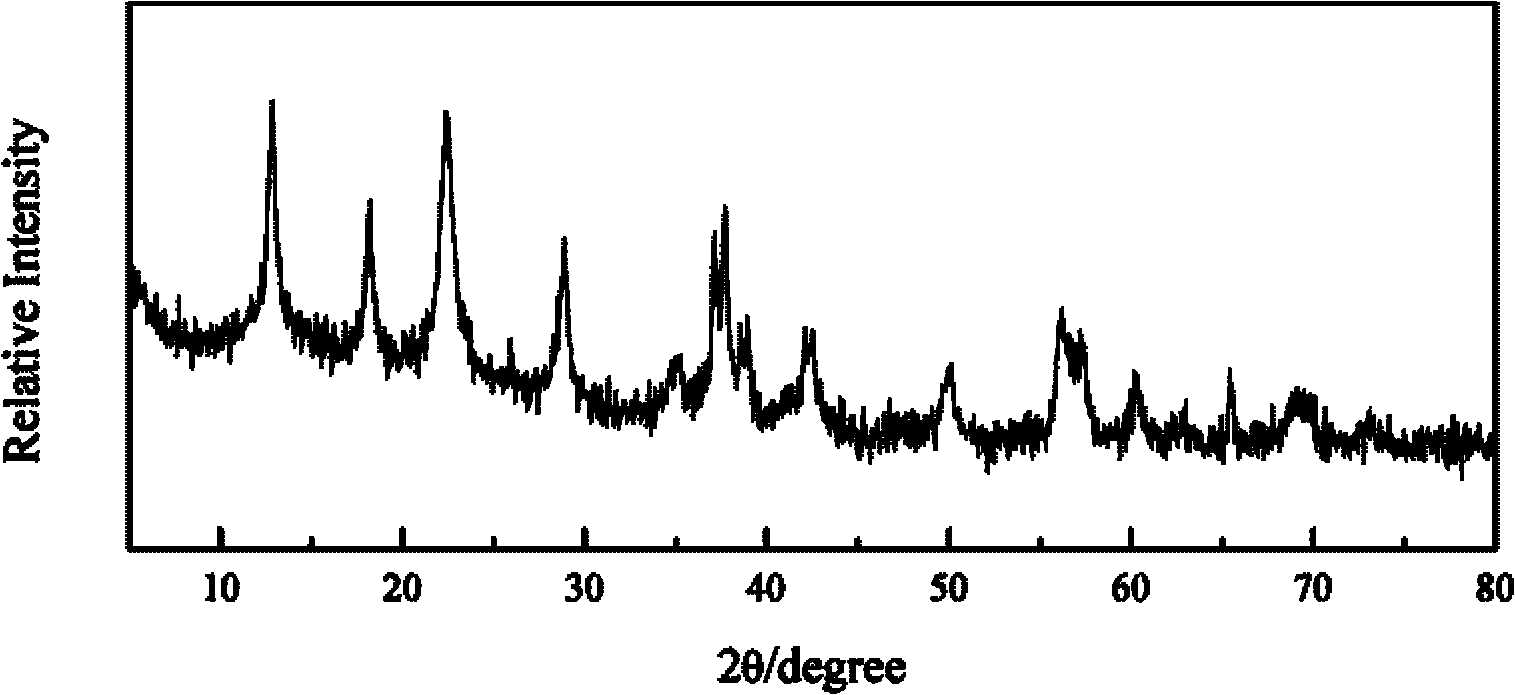

[0044] Obtain the XRD spectrogram of the cerium-manganese composite oxide catalyst of the present embodiment through detection, as figure 2 shown, from figure 2 It can be seen that the crystal phase of the cerium-manganese composite oxide catalyst in this example is α-MnO 2 Phase and γ-MnO 2 Mixture of phases. It is tested that the cerium-manganese composite oxide catalyst in this embodiment reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com