Catalyst for hydrogen production

A technology of catalysts and oxides, which is applied in the field of hydrogen production catalysts for catalytic reduction of water with visible light, can solve the problems of immaturity and achieve high hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

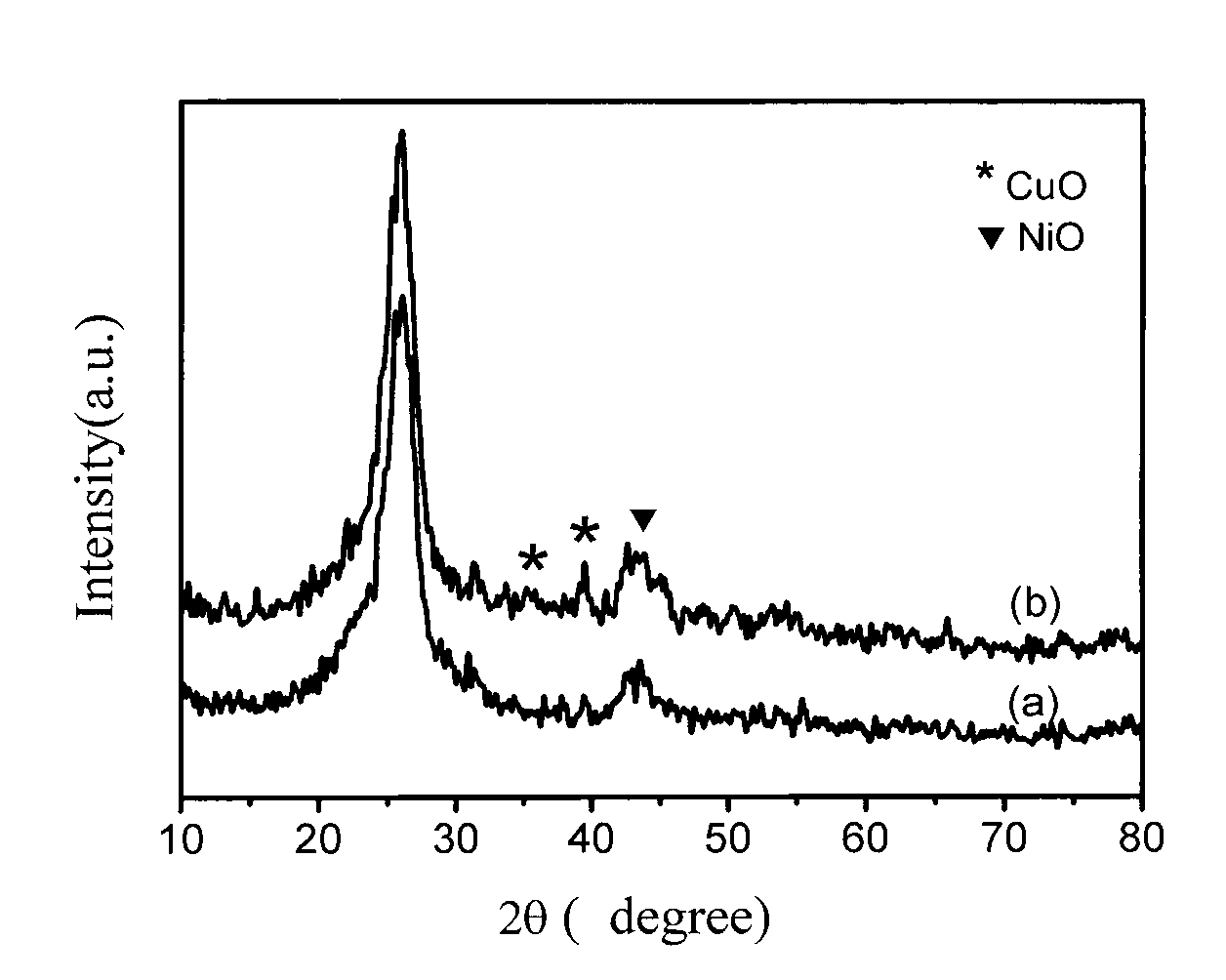

[0023] With 100mg carbon nanotubes (MWNTs, its XRD pattern is as figure 1 (a)), 0.38mL 0.1mol L -1 Copper nitrate, 0.4mL 0.1mol L -1 Nickel nitrate aqueous solution was added to a 100mL beaker and diluted with water to 20mL. After stirring at room temperature for 1 h, the water was evaporated to dryness to obtain a carbon nanotube-metal salt precursor.

[0024] The obtained precursor was put into a muffle furnace, and calcined at 300°C for 4 hours in an air atmosphere to obtain a carbon nanotube-CuO / NiO system. The XRD spectrum is as follows: figure 1 As shown in (b), the transmission electron microscope picture is as follows figure 2 shown.

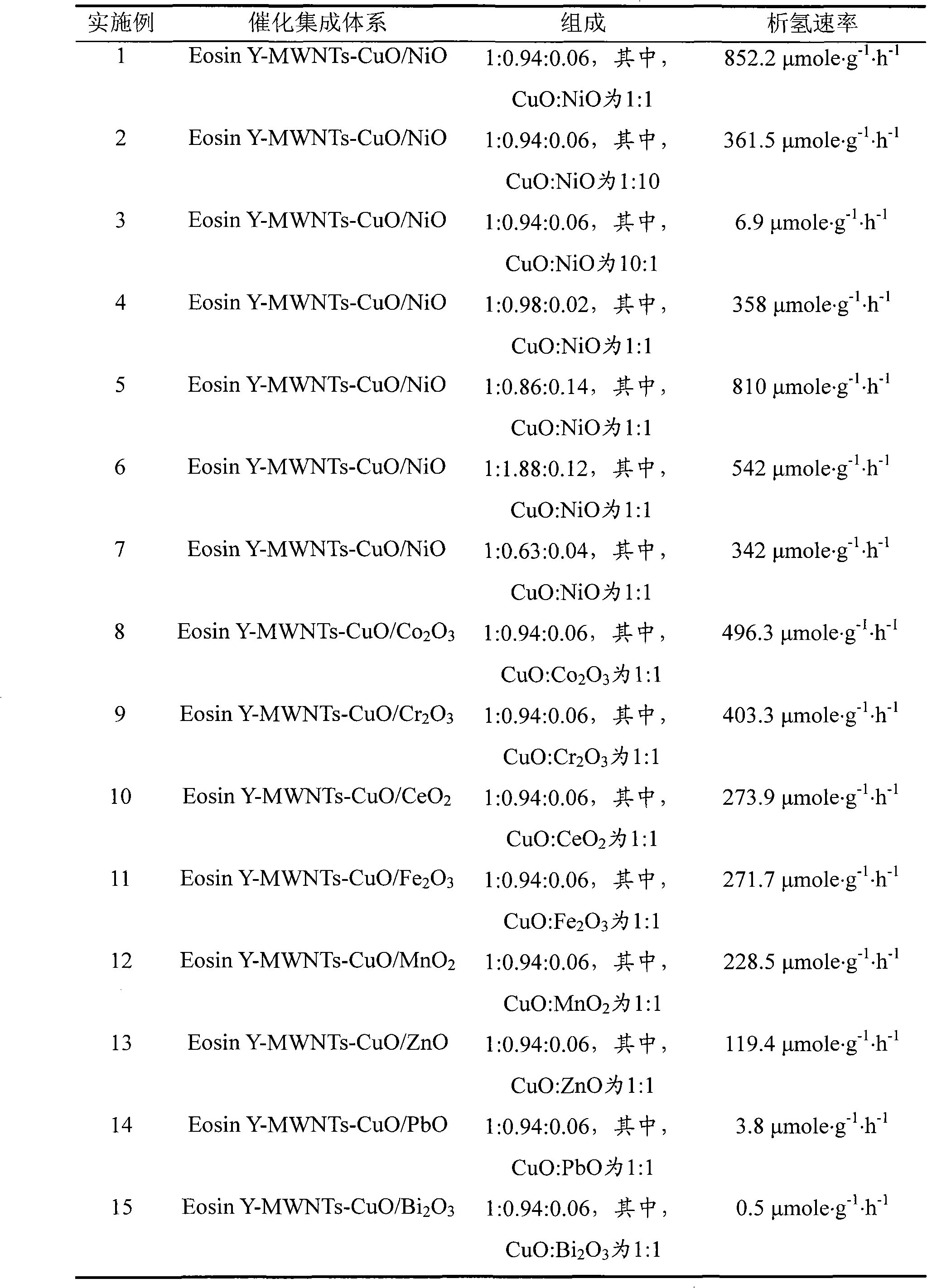

[0025] Put 80mg carbon nanotube-CuO / NiO system into the solution (1mg / mL) of 80mL eosin Y (Eosin Y), in N 2 Soak for 30min under protection to obtain the eosin-carbon nanotube-CuO / NiO catalytic integrated system, wherein the mass ratio of eosin, carbon nanotube and CuO / NiO is 1:0.94:0.06, wherein the mass ratio of CuO:NiO is 1:1. ...

Embodiment 2~15

[0027] The experimental procedure of embodiment 2~15 is identical with embodiment 1, and difference only is:

Embodiment 2

[0028] Add 0.006mmol copper nitrate, 0.06mmol nickel nitrate in embodiment 2, the mass ratio of eosin, carbon nanotube, CuO / NiO in the catalyst obtained is 1: 0.94: 0.06, wherein, the mass ratio of CuO: NiO is 1: 10;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com