Boron-carbide-containing graphite absorber ball and preparation process thereof

A preparation process, boron carbide technology, applied in nuclear engineering, manufacturing reactors, nuclear reaction control, etc., can solve the problems of poor wear resistance and moisture absorption resistance, high porosity, poor moisture absorption, etc., to achieve low labor cost consumption, High degree of automation, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

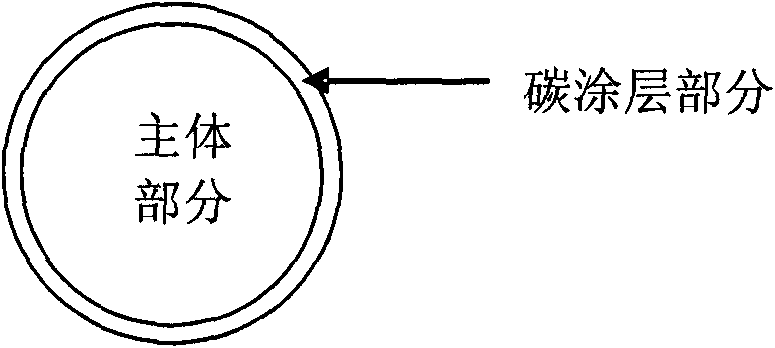

[0065] Such as figure 1 The main part shown is a graphite sphere composed of 5% boron carbide and 95% graphite component, with a diameter of 5mm, and the coating part is a carbon coating prepared by chemical vapor deposition process, and its thickness is 0.1um.

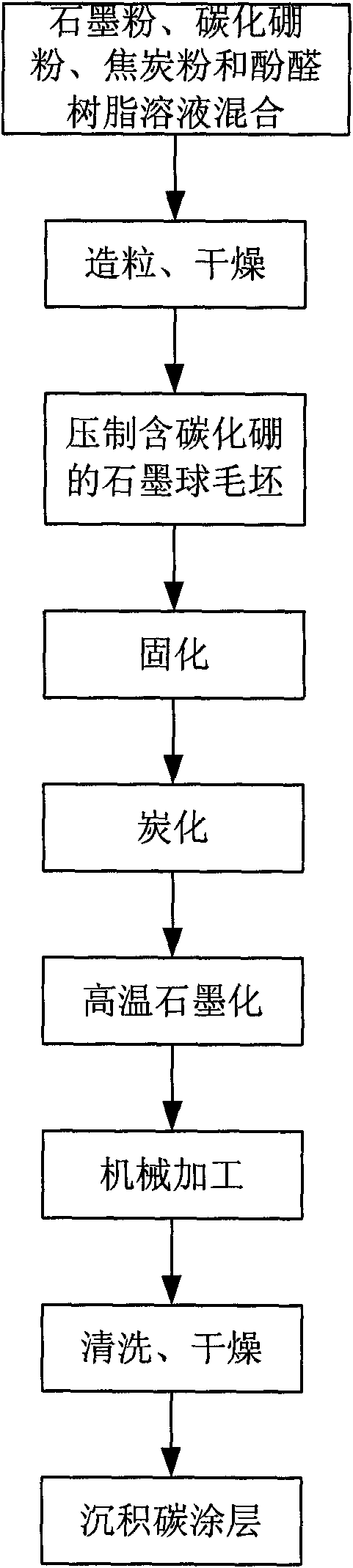

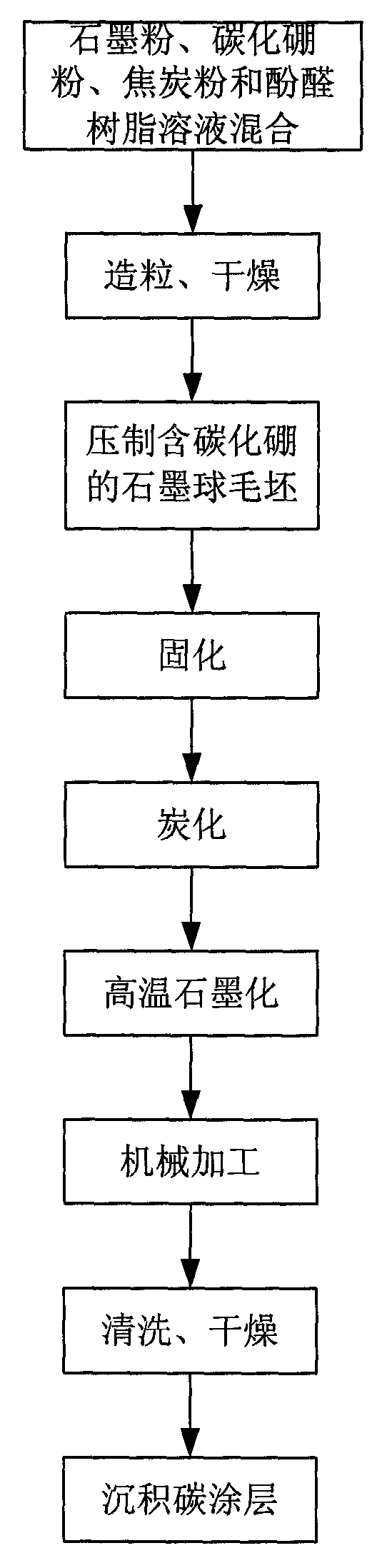

[0066] Preparation steps: (1) mix according to the mass ratio of graphite powder: boron carbide powder: coke powder: phenolic resin powder is 50:5:30:30, add alcohol to dissolve, and stir for 5h; (2) mix the material Carry out granulation and dry, obtain the granulated powder of uniform particle size, the diameter of granulated powder is 5um; (3) granulated powder is packed into spherical metal mould, adopts automatic packing continuous press to press, and pressing rate is 5um. pieces / min; the pressing pressure is 30kN, and the absorbing ball diameter of the pressed boron carbide absorbing ball blank is 6mm; (4) put the pressed graphite ball blank into the curing tank and heat up at a rate of 0.1°C / min to 150°C, keep...

Embodiment 2

[0068] Such as figure 1 The main part shown is a graphite sphere composed of 50% boron carbide and 50% graphite component, with a diameter of 15mm, and the coating part is a carbon coating prepared by a chemical vapor deposition process, and its thickness is 100um.

[0069] Preparation steps: (1) mix according to the mass ratio of graphite powder: boron carbide powder: coke powder: phenolic resin powder is 30:50:10:20, add alcohol to dissolve, and stir for 20h; (2) mix the material Carry out granulation and dry, obtain the granulated powder of uniform particle size, the diameter of granulated powder is 50um; (3) granulated powder is packed into spherical metal mould, adopts automatic packing continuous type press to press, and pressing rate is 30 um; pieces / min; the pressure of pressing is 100kN, and the diameter of the absorbing ball of the pressed boron carbide absorbing ball blank is 16mm; (4) put the pressed graphite ball blank into the curing tank and heat up at a rate of...

Embodiment 3

[0071] Such as figure 1 The main part shown is a graphite sphere composed of 25% boron carbide and 75% graphite component, with a diameter of 6mm. The coating part is a carbon coating prepared by chemical vapor deposition process, and its thickness is 10um.

[0072] Preparation steps: (1) mix graphite powder: boron carbide powder: coke powder: phenolic resin powder in a ratio of 50:25:20:10 by mass, add alcohol to dissolve, and stir for 10 hours; (2) mix the mixed material Carry out granulation and dry, obtain the granulated powder of uniform particle size, the diameter of granulated powder is 10um; (3) granulated powder is packed into spherical metal mould, adopts automatic packing continuous press to press, and pressing rate is 10 pieces / min; the pressing pressure is 60kN, and the absorbing ball diameter of the pressed boron carbide absorbing ball blank is 7mm; (4) put the pressed graphite ball blank into the curing tank and heat up at a rate of 0.5°C / min to 180°C, keep war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com