Method for synthesizing high-purity aluminum silicon carbon superfine powder

A technology of ultrafine powder and aluminum silicon carbon, which is applied in the field of ceramic materials, can solve the problems of high raw material cost, impossibility of large-scale industrial application, high price of aluminum silicon carbon, etc., and achieves a simple and easy method, high efficiency and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

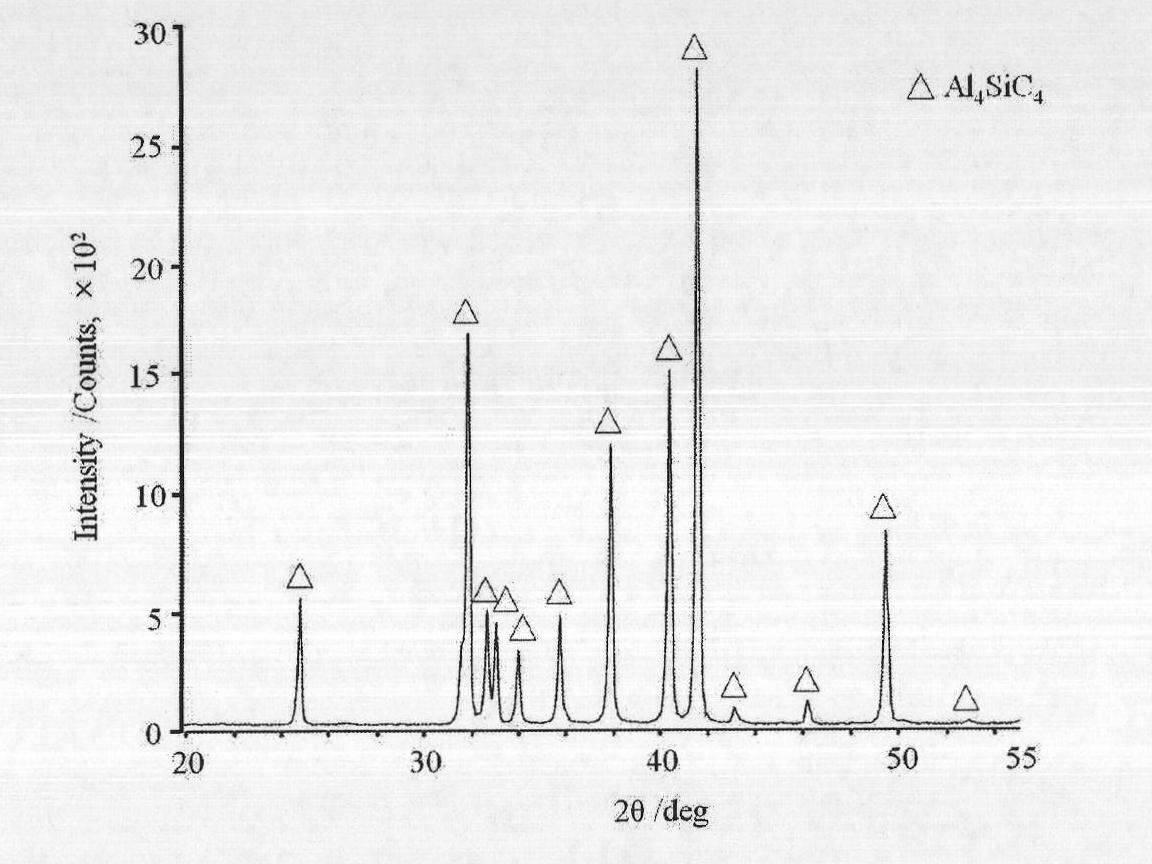

[0023] Embodiment 1, synthetic aluminum silicon carbon superfine powder

[0024] The selected formula is: carbon black (average particle size 2μm): Al 2 o 3 Fine powder (average particle size 3μm): Al 2 Si 2 o 5 (OH) 4 (Kaolin, average particle size 5 μm) = 27:45:28 (mass ratio), weigh the ingredients, add alcohol until the material is submerged, fully stir and mix on a vacuum heating rotary mixer, and dry the obtained mixture at 110°C . After drying, the mixture is put into a graphite crucible (the graphite crucible is not covered), the graphite crucible is placed in an electric furnace, heated at 1600°C in a vacuum atmosphere, and kept for 8 hours. After cooling, the impurity-enriched layer on the upper surface is removed, that is Obtain aluminum silicon carbon ultrafine powder with an average particle size of 2-5 μm, in which Al 4 SiC 4 The SiC content is 99.1%, and the SiC content is 0.3%.

Embodiment 2

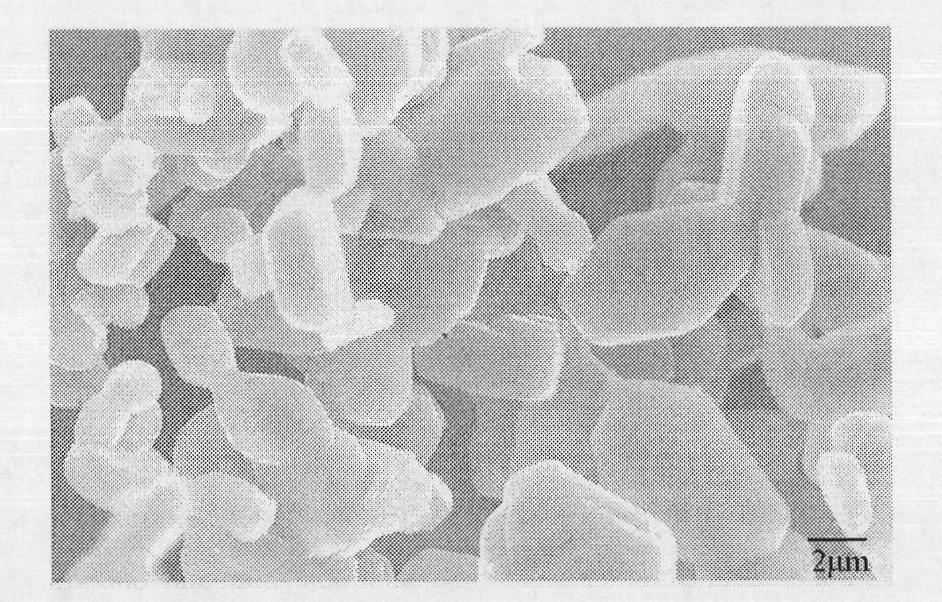

[0025] Embodiment 2, synthetic aluminum silicon carbon superfine powder

[0026] The selected formula is: graphite (average particle size 5 μm): fused corundum (average particle size 5 μm): Al 2 Si 2 o 5 (OH) 4 (Kaolin, average particle size 3μm)=27:47:26 (mass ratio), weigh the ingredients, add alcohol until the material is submerged, fully stir and mix on a vacuum heating rotary mixer, and dry the obtained mixture at 110°C . After drying, the mixture is put into a graphite crucible (the graphite crucible is not covered), the graphite crucible is placed in an electric furnace, heated at 1600°C in a vacuum atmosphere, and kept for 8 hours. After cooling, the impurity-enriched layer on the upper surface is removed, that is Obtain aluminum silicon carbon ultrafine powder with an average particle size of 2-5 μm, in which Al 4 SiC 4 The content is 99.3%. The scanning electron microscope photo of the aluminum silicon carbon ultrafine powder is as follows: figure 2 shown. ...

Embodiment 3

[0028] Embodiment 3, synthetic aluminum silicon carbon superfine powder

[0029] The selected formula is: petroleum coke (average particle size 8 μm): sintered corundum (average particle size 5 μm): Al 2 Si 2 o 5 (OH) 4(Kaolin, average particle size 8 μm)=27:45:28, weigh the ingredients, add alcohol until the material is submerged, fully stir and mix on a vacuum heating rotary mixer, and dry the obtained mixture at 110°C. After drying, put the mixture into a graphite crucible (the graphite crucible is not covered), put the graphite crucible into an electric furnace, heat at 1700°C in a high-purity Ar atmosphere of 99.99% or more, keep it warm for 10 hours, and remove impurities on the upper surface after cooling Concentration layer, that is, to obtain aluminum silicon carbon ultrafine powder with an average particle size of 2-5 μm, in which Al 4 SiC 4 The SiC content is 99.1%, and the SiC content is 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com