Preparation method of nano crystal MnZn ferrite with high saturation magnetization intensity

A technology of magnetization and nanocrystals, which is applied in the preparation of nanocrystalline MnZn ferrite with low blocking temperature and high saturation magnetization, which can solve the problems of poor frequency characteristics, low saturation magnetic induction, and low permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of nanocrystalline MnZn ferrite with high saturation magnetization and low blocking temperature, the preparation method comprises the steps of:

[0057] 1. Prepare the solution (by molar ratio)

[0058] ①, 1.538mol / L Fe, Mn, Zn mixed solution

[0059] Press Fe 2 o 3 :MnO:ZnO=52.8:24.2:13 (mol%), weigh 439.0g of Fe(NO3) 3 9H 2 O, 50% Mn(NO 3 ) 2 Solution 185.0g, 38.7g of Zn(NO 3 ) 2 ·6H 2 O; Dissolve in distilled water and make the volume 1L;

[0060] ②, 1.538mol / L NH 4 HCO 3 the solution

[0061] Weigh 140.8gNH 4 HCO 3 ·H 2 O; Dissolve in distilled water and make the volume 1L;

[0062] ③, 4.0mol / L NaOH solution

[0063] Weigh 160.0g of analytically pure NaOH; dissolve it in distilled water and set the volume to 1L;

[0064] 2. Preparation of nanocrystalline MnZn ferrite powder by phase inversion method

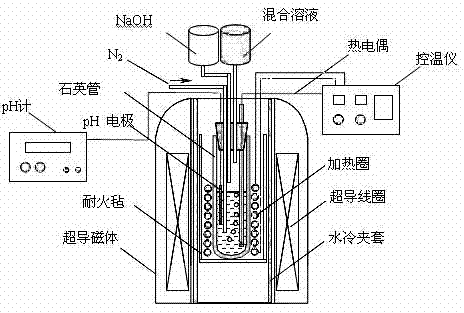

[0065] (1) Measure 2 parts of 50ml of the above-mentioned 1.538mol / L Fe, Mn, Zn mixed solution into a quartz tube and place it in...

Embodiment 2

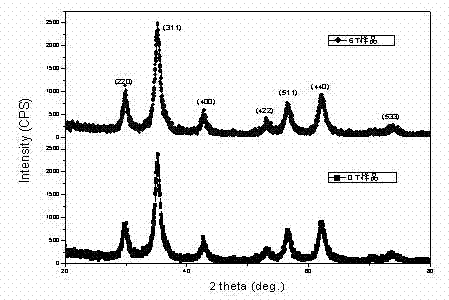

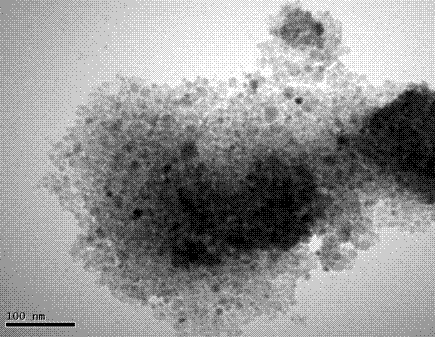

[0078] The preparation method is the same as that of Example 1, but the magnetic field strength is 2T, and the nanocrystalline MnZn ferrite with high saturation magnetization and low blocking temperature is in the form of powder with a typical spinel structure and the grain size is about 10 nanometers.

Embodiment 3

[0080] The preparation method is the same as in Example 1, but the magnetic field strength is 4 T, and the nanocrystalline MnZn ferrite with high saturation magnetization and low blocking temperature is in the form of powder, with a typical spinel structure, and the grain size is about 10 nanometers. .

[0081] Embodiment 1, 2 and embodiment 3 gained high saturation magnetization, the saturation magnetization of the nanocrystalline MnZn ferrite of low blocking temperature is shown in Fig. 5 (a) with the change of magnetic field, from Figure 5(a) It can be seen that the saturation magnetization increases with the strengthening of the preparation magnetic field, which is because the preparation magnetic field affects the ion occupancy of the ferrite material, which leads to the change of the saturation magnetization.

[0082] The blockage temperature of the nanocrystalline MnZn ferrite with high saturation magnetization and low blockage temperature of embodiment 1, 2 and embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com