Process for forming light-weight and high-pressure gas bottle made of composite material

A technology of composite material and molding process, which is applied in other household appliances, household appliances, applications, etc., to achieve the effect of wide application prospects, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

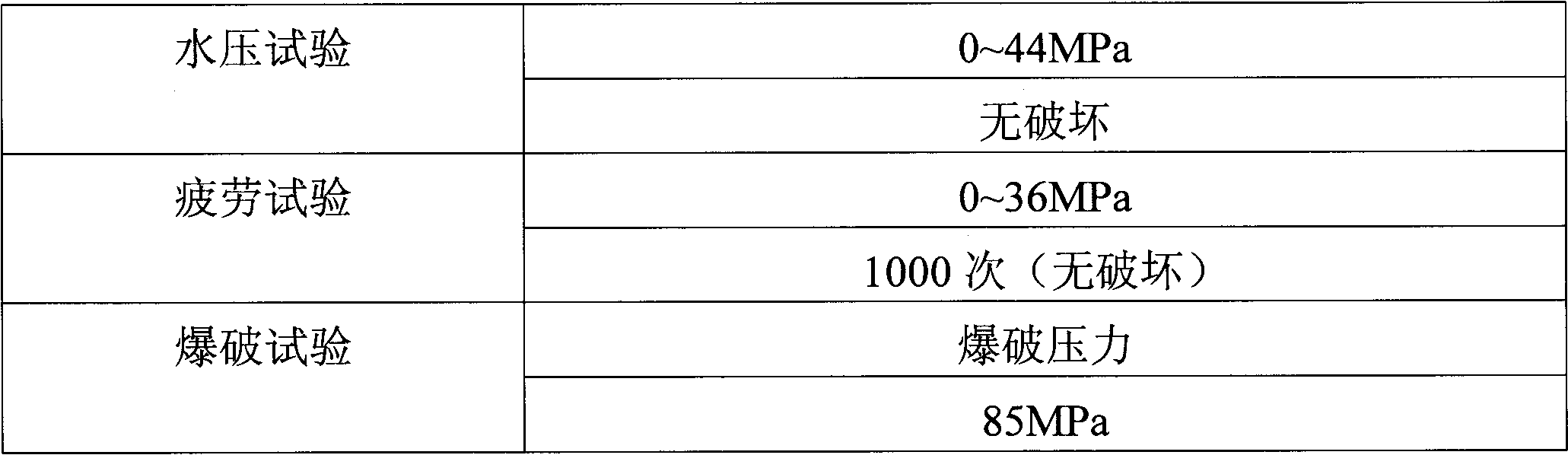

Embodiment 1

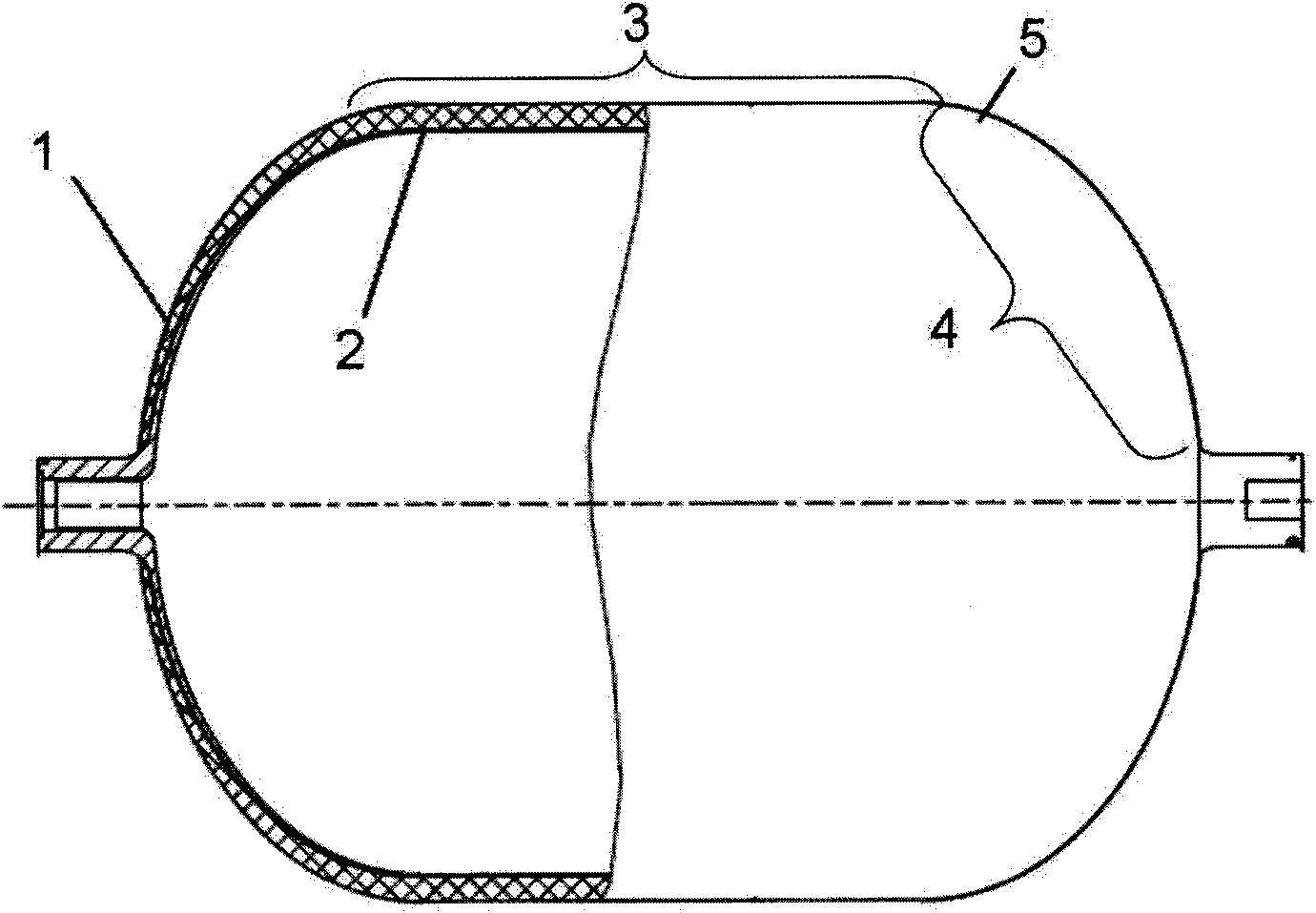

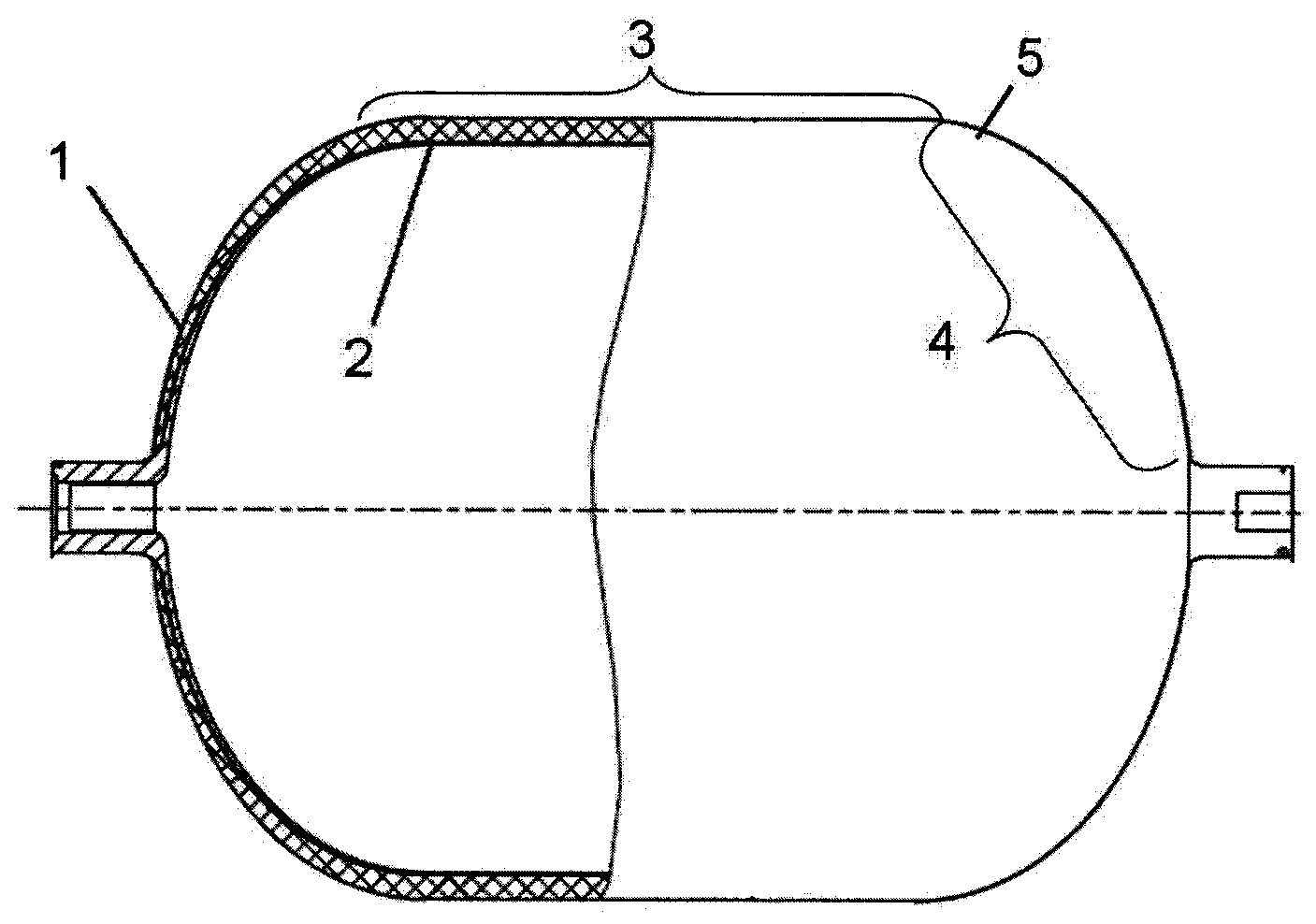

[0021] A lightweight high-pressure composite gas cylinder was prepared according to the following steps:

[0022] Step 1: The outer surface of the metal lining of the gas cylinder is treated. The metal lining of the gas cylinder used is formed by spinning, with a diameter of 400mm, a length of the barrel section of 300mm, and a length of the head of 150mm. The outer surface of the metal lining is subjected to sand blasting, the sand blowing pressure is 0.2MPa, the sand mesh is 40 mesh, and the outer surface of the metal inner lining is evenly sand blasted, and the sand blowing step is realized by the existing process;

[0023] Step 2, prepare epoxy resin glue, proportioning is epoxy resin TDE-85 (1,2-epoxycyclohexane 4,5 dicarboxylic acid epoxy resin), diluent 669 epoxy resins (ethylene glycol dishrunk Glyceryl ether), amine curing agent DDM (4,4'-diaminodiphenylmethane) and accelerator 2-4-dimethylimidazole are mixed into gel according to the ratio of 1:0.6:0.3:0.005 by weigh...

Embodiment 2

[0032] According to the same steps as in Example 1, the light-weight high-pressure composite gas cylinder is prepared, and the difference is that:

[0033] (1) The diameter of the metal lining of the gas cylinder used in step 1 is 350mm, the length of the barrel section is 300mm, and the length of the head is 150mm;

[0034] (2) In step 2, the epoxy resin glue is made of amino tetrafunctional epoxy resin, phthalate epoxy resin, m-phenylenediamine and 2-methylimidazole according to the ratio of 1: 0.6: 0.3: 0.005 by weight mix;

[0035](3) The fiber used in step 3 is T300 continuous fiber, and the soaking time is controlled at about 3 seconds.

[0036] (4) The specific winding implementation process in step 4 is four layers of hoop winding, two layers of longitudinal winding, the longitudinal winding angle is ±12 degrees, four layers of hoop winding, two layers of longitudinal winding, and the longitudinal winding angle of ±18 degrees , two layers of longitudinal winding, the...

Embodiment 3

[0041] According to the same steps as in Example 1, the light-weight high-pressure composite gas cylinder is prepared, and the difference is that:

[0042] (1) The diameter of the metal lining of the gas cylinder used in step 1 is 500mm, the length of the barrel section is 600mm, and the length of the head is 150mm;

[0043] (2) In step 2, the epoxy resin glue is mixed by ordinary bisphenol A type epoxy resin, tetrahydrophenyldimethyl ester epoxy resin, m-aminomethylamine and imidazole according to the ratio of 1:0.4:0.5:0.005 by weight ;

[0044] (3) The fiber used in step 3 is T100 continuous fiber, and the soaking time is controlled at about 6 seconds;

[0045] (4) The specific winding implementation process in step 4 is four layers of hoop winding, two layers of longitudinal winding, the longitudinal winding angle is ±16 degrees, four layers of hoop winding, two layers of longitudinal winding, and the longitudinal winding angle of ±21 degrees , four layers of hoop windin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com