Plastic extruding machine with curve-shaped machine neck flow channel

A curved, extruder technology, applied in the field of cable production, can solve the problems of dead coke decomposition products, low pressure, easy to produce dead edges on the flow channel wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

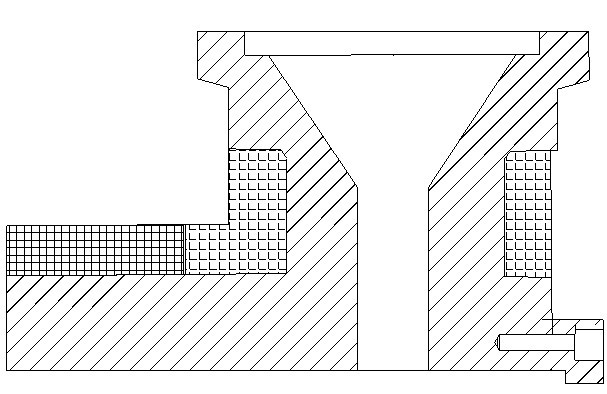

Image

Examples

Embodiment Construction

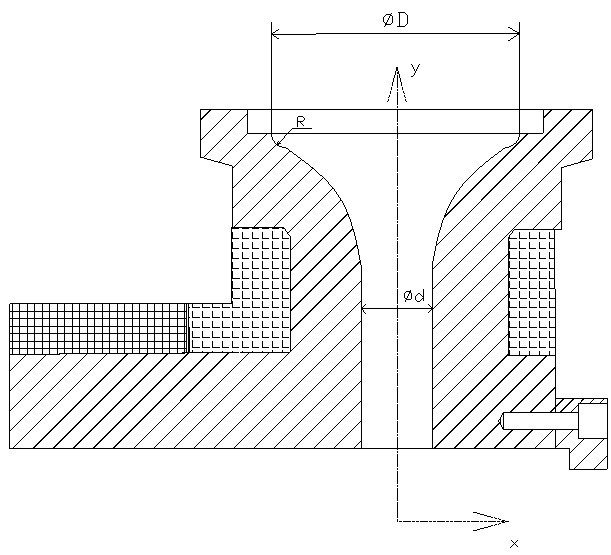

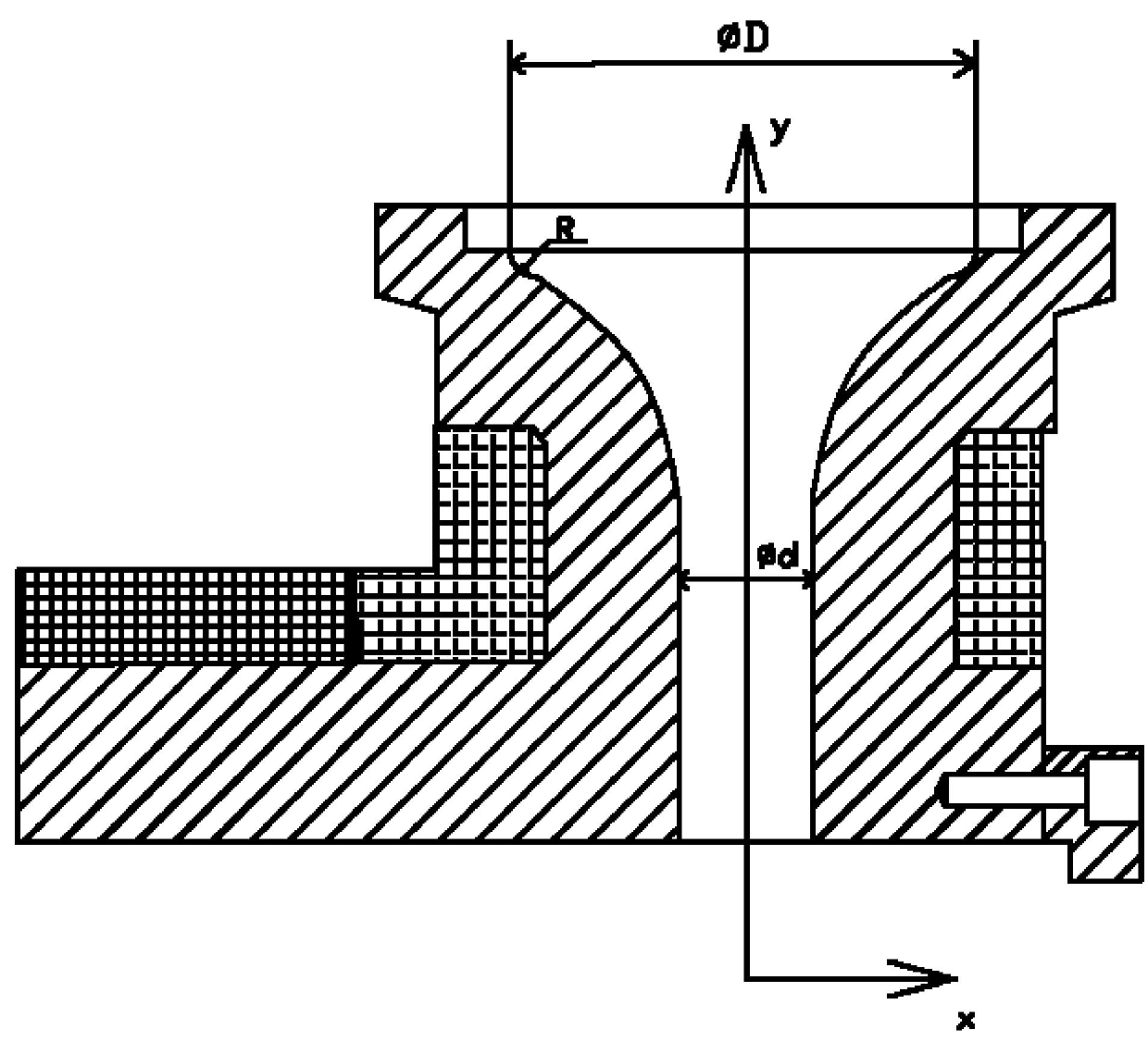

[0014] like figure 2 , the extruder of the present invention has a curved neck runner, and the longitudinal section shape of the neck runner is curved, and the curve is:

[0015] (1) The neck flow channel adopts y=ax 2 function.

[0016] (2) The constant a is determined by the diameter of the screw barrel of the fuselage and the diameter of the inflow inlet of the machine head, specifically a= (Note: R is the arc radius of the horn edge; D is the large diameter of the horn, that is, the inner diameter of the fuselage screw barrel; d It is the small diameter of the horn, that is, the diameter of the hole that flows into the machine head).

[0017] (3) The horn-shaped edge is round and smooth (circle radius R ), take the circumference of the circle , no dead ends.

[0018] (4) The start point to the end point of the entire horn-shaped curve is accurately positioned, and there is no dead point in surface processing.

[0019] The present invention provides an idea and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com