Flow line production method and device for construction partition wall board

A production method and technology for partition wall panels, which are used in construction, building components, building materials, etc., can solve the problems of increasing manufacturing costs, unstable internal structure, and high rejection rate, reducing deformation and damage ratios, and reducing transportation processes. , The effect of reducing the cost of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

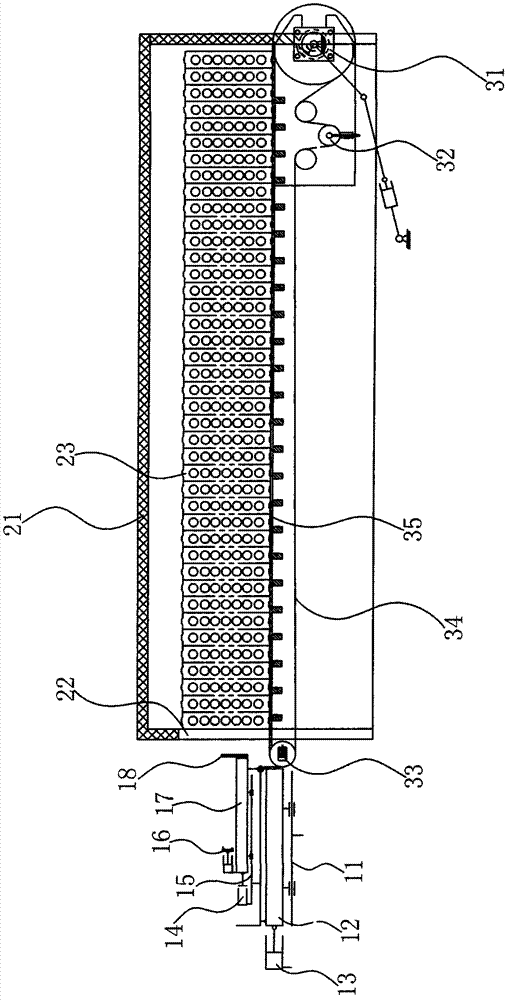

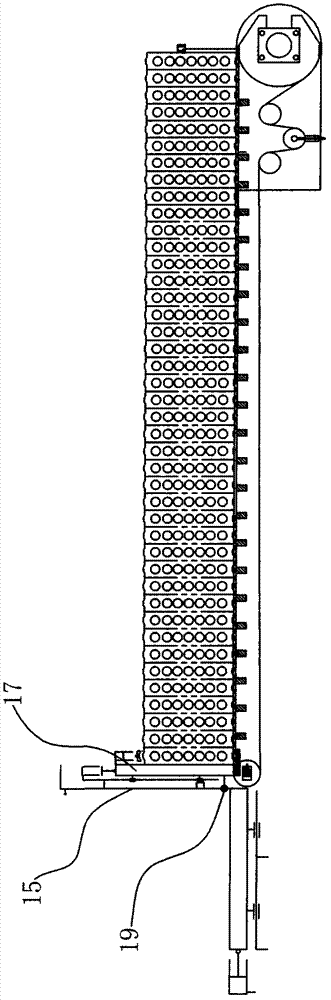

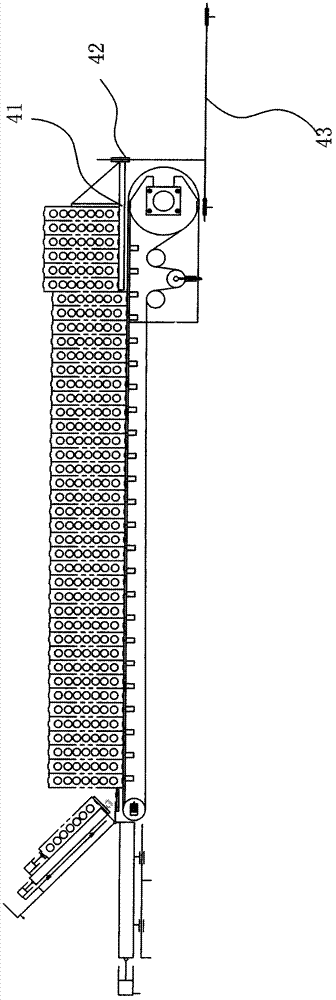

[0030] The assembly line production method of the building partition wall board can be used for the assembly line type uninterrupted production of various composite or inorganic material building partition wall boards. Such as figure 1 and figure 2 As shown, in the assembly line production method, the partition wall panel moving and turning mechanism turns over the formed building partition wall panel to a maintenance conveying mechanism, and the partition wall panel moving and turning mechanism includes a turning frame 15, and the turning frame One end is rotated and set, and the partition wall panel fixing plate 17 is slidably set on the turning frame. On the conveying mechanism; the moving and turning mechanism of the partition wall board includes a horizontal guide rail 11, on which the flip frame is slidably set, and the end of the flip frame close to the maintenance conveying mechanism is rotated and set by the rotating shaft 19; the partition wall plate fixed plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com