Electric heating wire of lighter

A technology of electric heating wire and lighter, which is applied in the direction of ohmic resistance heating parts, combustion ignition, heating elements, etc. It can solve the problems of undefined electric heating parts and parts configuration relationship, etc., and achieve small thermal inertia, reliable ignition and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

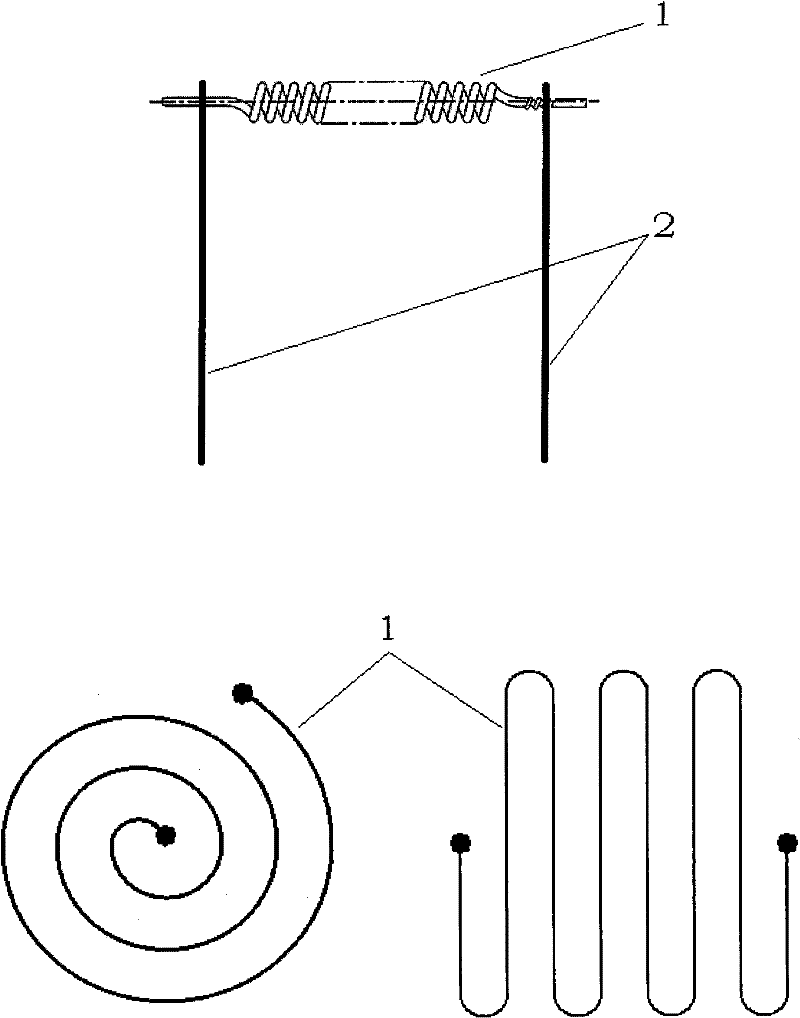

[0014] refer to figure 1 According to the cold resistance 1.7-45Ω, the heating wire 1 is wound into a spiral structure to make a linear or flat shape, or made into a flat shape with a flat electric heating wire. The best cold resistance is 6-13Ω, and the two ends are respectively connected to two metal rods. 2 One end is made into an integrated plug-in by welding or cold pressing.

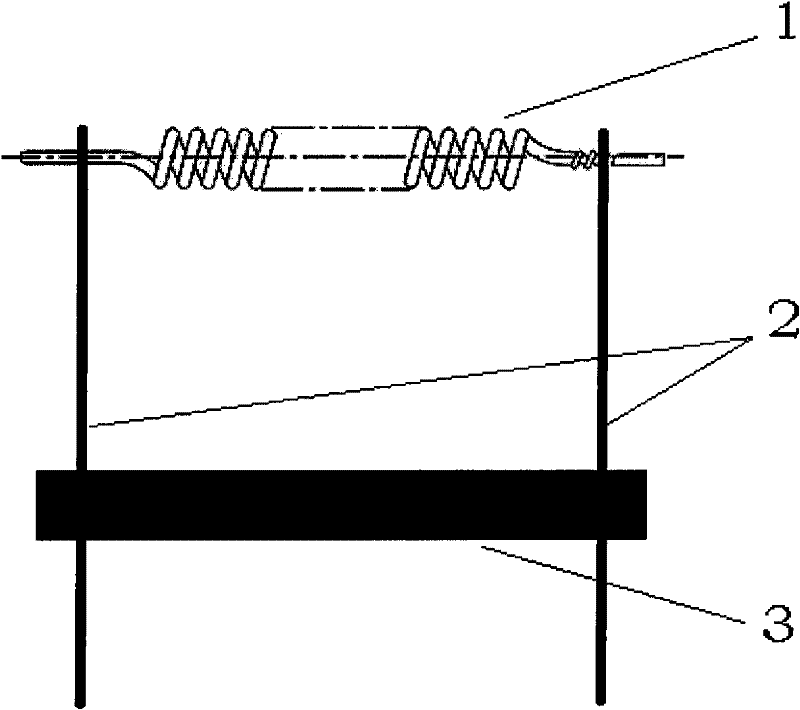

[0015] figure 2 The two metal rods 2 shown can be made into parallel separate placements, and the middle is fixed with an "H" type of insulators 3 such as plastics and glass, and then fixed with the heating wire 1 two ends as an integrated pull-out plug-in.

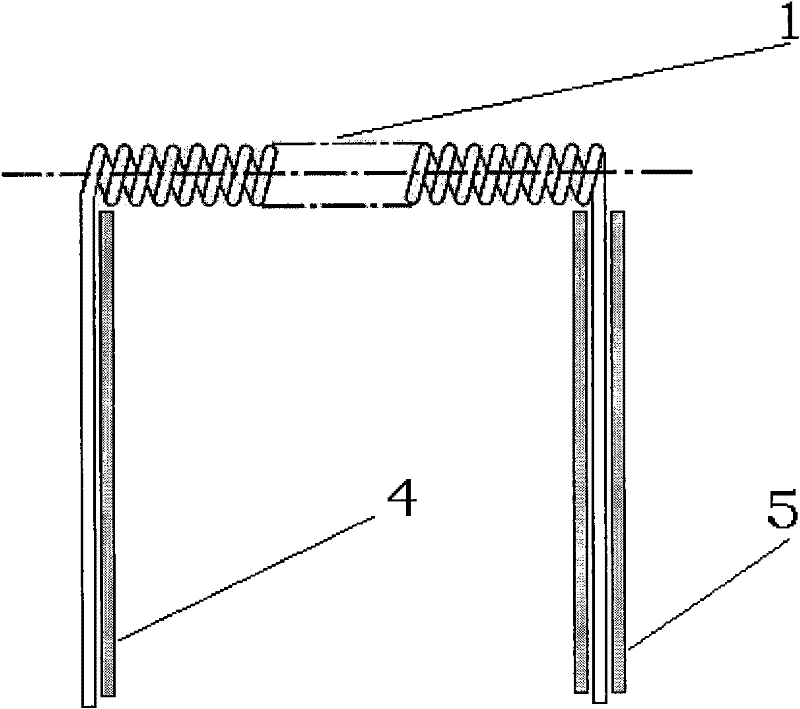

[0016] exist image 3 Among them, the spiral part of the heating wire 1 is a horizontal wire, and the straight wires on both sides are bent into vertical wires to form a "door" shape. The vertical wires on both sides of the heating wire are fixed together with plates 4 or tubes 5: the two vertical wires are cold-pressed or welded with meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com