Preparation method and application of Ag/AgBr@TiO2/CA electrode

An electrode and the resulting technology are applied in battery electrodes, magnetic field/electric field water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., and can solve the problems of ineffective use of microorganisms, secondary pollution, high voltage, etc. Achieve the effect of improving photocatalytic performance, reducing energy consumption and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

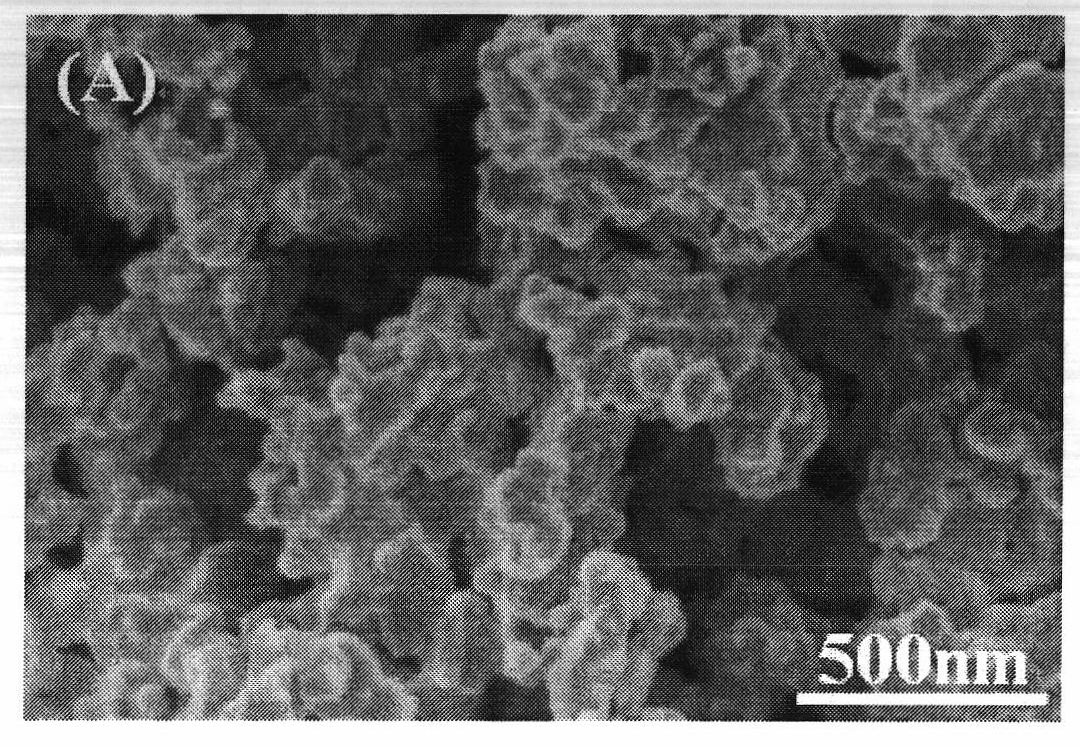

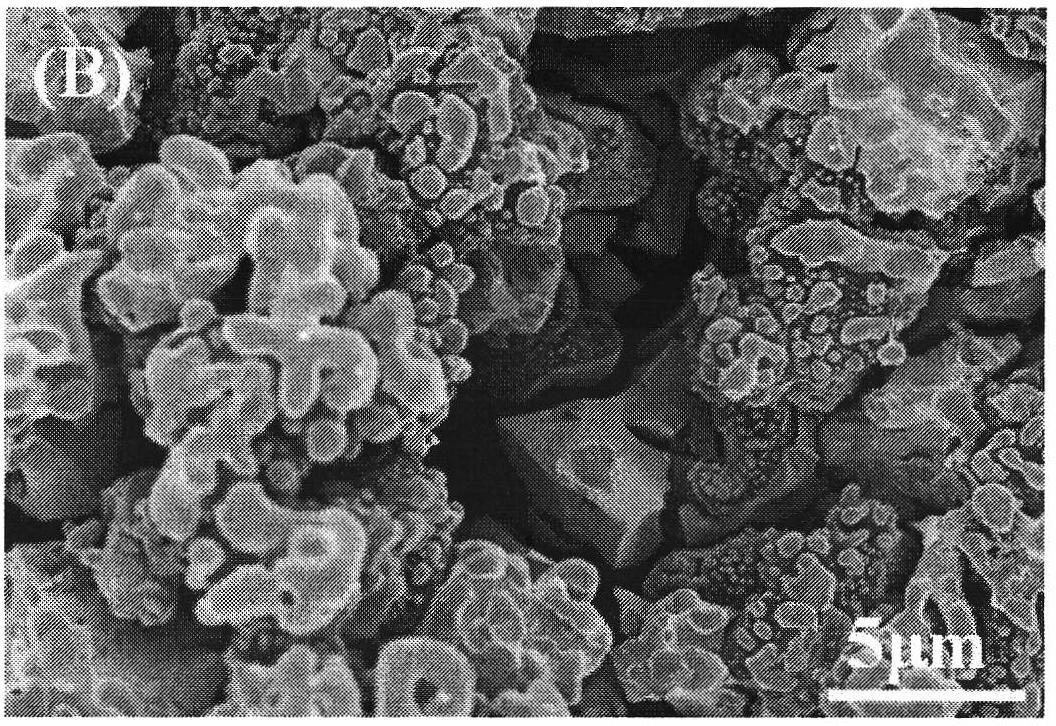

[0034] Ag / AgBr@TiO 2 / CA electrode preparation

[0035] (1) In a cylindrical glass mold with a diameter of 1 cm and a length of 20 cm, add resorcinol (77.08 g), formaldehyde (42 g), sodium carbonate (0.07 g) and water (220.5g), leave standstill to obtain phenolic resin, the rod-shaped phenolic resin obtained is carried out solvent replacement in acetone (surface tension is less than 30m N / m), the water molecule in its network structure is replaced by organic reagent , the time is 6 days, and the organic reagent is replaced every 1 day; then after drying at room temperature, the temperature is programmed to 900 ° C in a tube furnace and kept for 4 hours for carbonization to obtain a rod-shaped carbon aerogel;

[0036](2) Stir butyl titanate (40mL), absolute ethanol (120mL) and acetylacetone (4mL) with a volume ratio of 1:3:0.1 with a magnetic stirrer for 30min, and then add dropwise a volume ratio of 1:4: A mixed solution of 20 nitric acid (2mL), deionized water (8mL) and abs...

Embodiment 2

[0043] Ag / AgBr@TiO 2 / CA electrode preparation

[0044] (1) In a cylindrical glass mold with a diameter of 1 cm and a length of 20 cm, add resorcinol (77.08 g), formaldehyde (42 g), sodium carbonate (0.35 g) and water (220.5g), leave standstill to obtain phenolic resin, the rod-shaped phenolic resin obtained is carried out solvent replacement in acetone (surface tension is less than 30m N / m), the water molecule in its network structure is replaced by organic reagent , the time is 6 days, and the organic reagent is replaced every 1 day; then after drying at room temperature, the temperature is programmed to 900 ° C in a tube furnace and kept for 4 hours for carbonization to obtain a rod-shaped carbon aerogel;

[0045] (2) Stir butyl titanate (40mL), absolute ethanol (120mL) and acetylacetone (20mL) with a volume ratio of 1:3:0.5 with a magnetic stirrer for 30min, and then add dropwise a volume ratio of 1:4: 30 of nitric acid (2mL), deionized water (8mL) and absolute ethanol (...

Embodiment 3

[0051] Ag / AgBr@TiO 2 / CA electrode preparation

[0052] (1) In a cylindrical glass mold with a diameter of 1 cm and a length of 20 cm, add resorcinol (77.08 g), formaldehyde (42 g), sodium carbonate (0.21 g) and water (220.5g), leave standstill to obtain phenolic resin, the rod-shaped phenolic resin obtained is carried out solvent replacement in acetone (surface tension is less than 30m N / m), the water molecule in its network structure is replaced by organic reagent , the time is 6 days, and the organic reagent is replaced every 1 day; then after drying at room temperature, the temperature is programmed to 900 ° C in a tube furnace and kept for 4 hours for carbonization to obtain a rod-shaped carbon aerogel;

[0053] (2) Stir butyl titanate (40mL), absolute ethanol (120mL) and acetylacetone (12mL) with a volume ratio of 1:3:0.3 with a magnetic stirrer for 30min, and then add dropwise a volume ratio of 1:4: 25 of nitric acid (2mL), deionized water (8mL) and absolute ethanol (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com