Semiconductor package part and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of reducing the structural strength of the second semiconductor package 20 and the size of the second semiconductor package 20 cannot be reduced And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The following preferred embodiments are proposed as an illustration of the present invention, but the content of the embodiments is only for illustration purposes, and the drawn drawings are for illustration purposes, and are not used to limit the protection scope of the present invention. Furthermore, the illustrations of the embodiments also omit unnecessary components to clearly show the technical characteristics of the present invention.

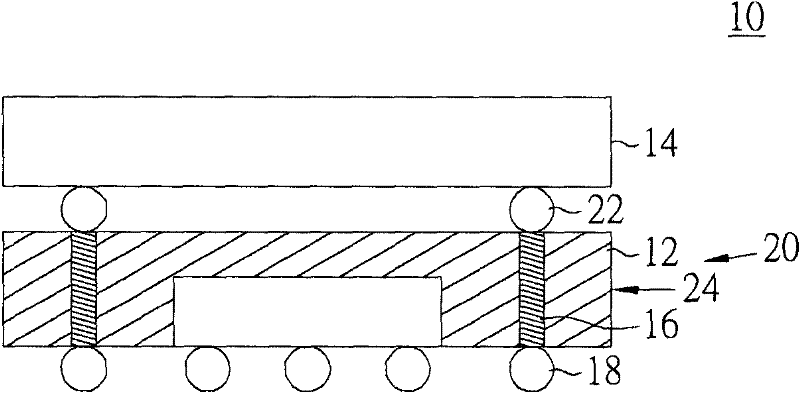

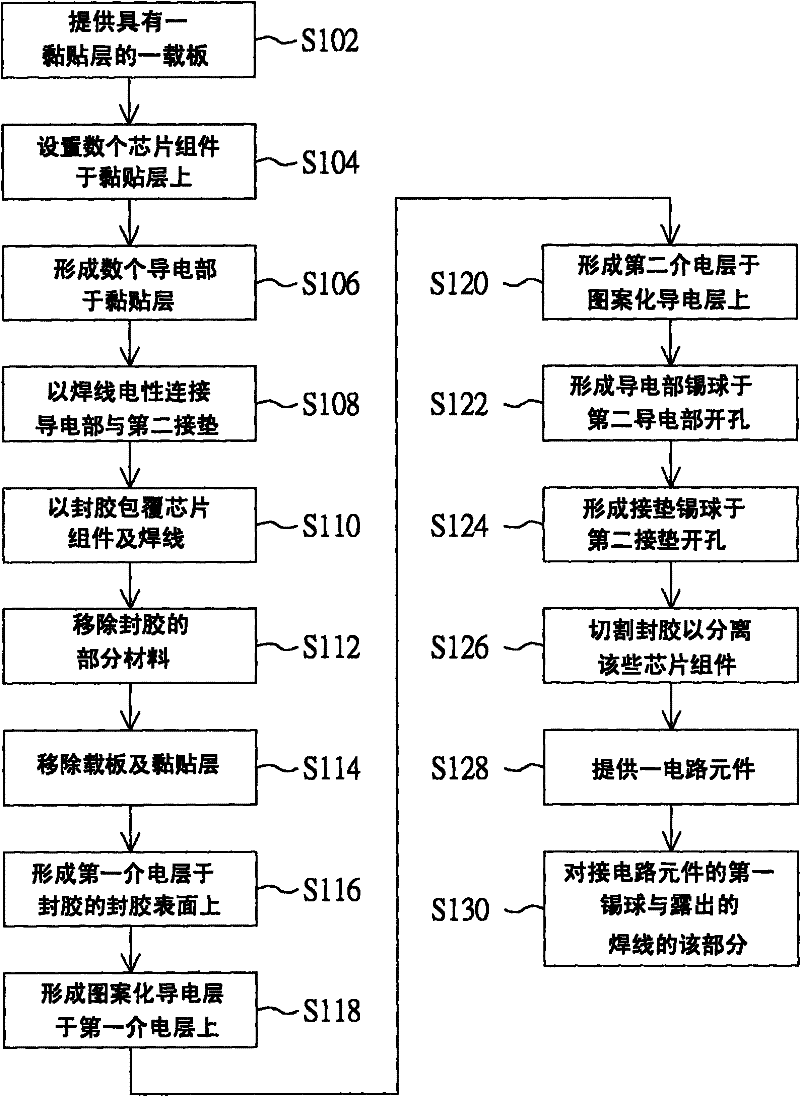

[0066] Please refer to figure 2 , which shows a cross-sectional view of the semiconductor package according to the first embodiment of the present invention. The semiconductor package 100 is a stacked semiconductor package, which includes a chip assembly 102, a metal bonding wire 104, a sealant 106, a conductive portion 108, a first dielectric layer 110, a second dielectric layer 116, A patterned conductive layer 112 and a semiconductor device 114 . The semiconductor component 114 here is, for example, a chip or another semicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com