Double-nail-head wax sealing and nailing machine

A technology of nail heads and glue nails, which is applied in the field of double nail head sealing nail box machines, can solve the problems of time-consuming and laborious, easy to rust and break, and unfavorable stability of packing boxes, so as to reduce the number of adjustments, prevent rust and break, The effect of convenient double-row continuous binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

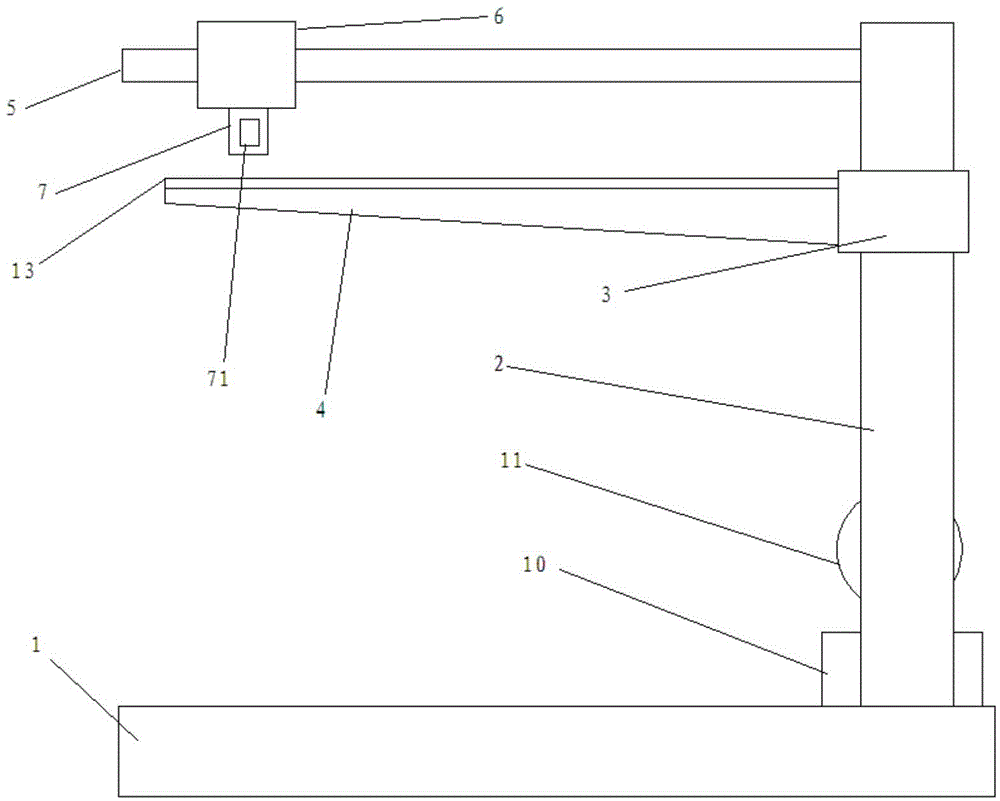

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, thereby making a clearer definition of the protection scope of the present invention

[0015] Such as Figure 1-Figure 2 As shown, a double nail head sealing nail box machine includes a base 1, two vertical poles 2 are vertically arranged on the base 1, and longitudinal sliding sleeves 3 are arranged on the two vertical poles 2. The same side of the sliding sleeve 3 is provided with an abutment plate 4, and a cantilever 5 is provided at the top of the two vertical rods 2. The cantilever 5 is parallel to the abutment plate 4 and is located directly above the abutment plate 4. The cantilever 5 is provided with Horizontal sliding sleeve 6, a nail head 7 is provided below the horizontal sliding sleeve 6, and a glue bin 71 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com