Method for producing surface-densified powder metallurgic gear

A powder metallurgy and production method technology, applied in the field of powder metallurgy surface dense gear production, can solve the problems of uneven density of the gear surface, the influence of elastic-plastic deformation, and the inability to control the elastic-plastic deformation of the gear well, so as to achieve gear tooth resistance The effect of improving fatigue resistance and wear resistance, improving performance and quality, and shortening the research and development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

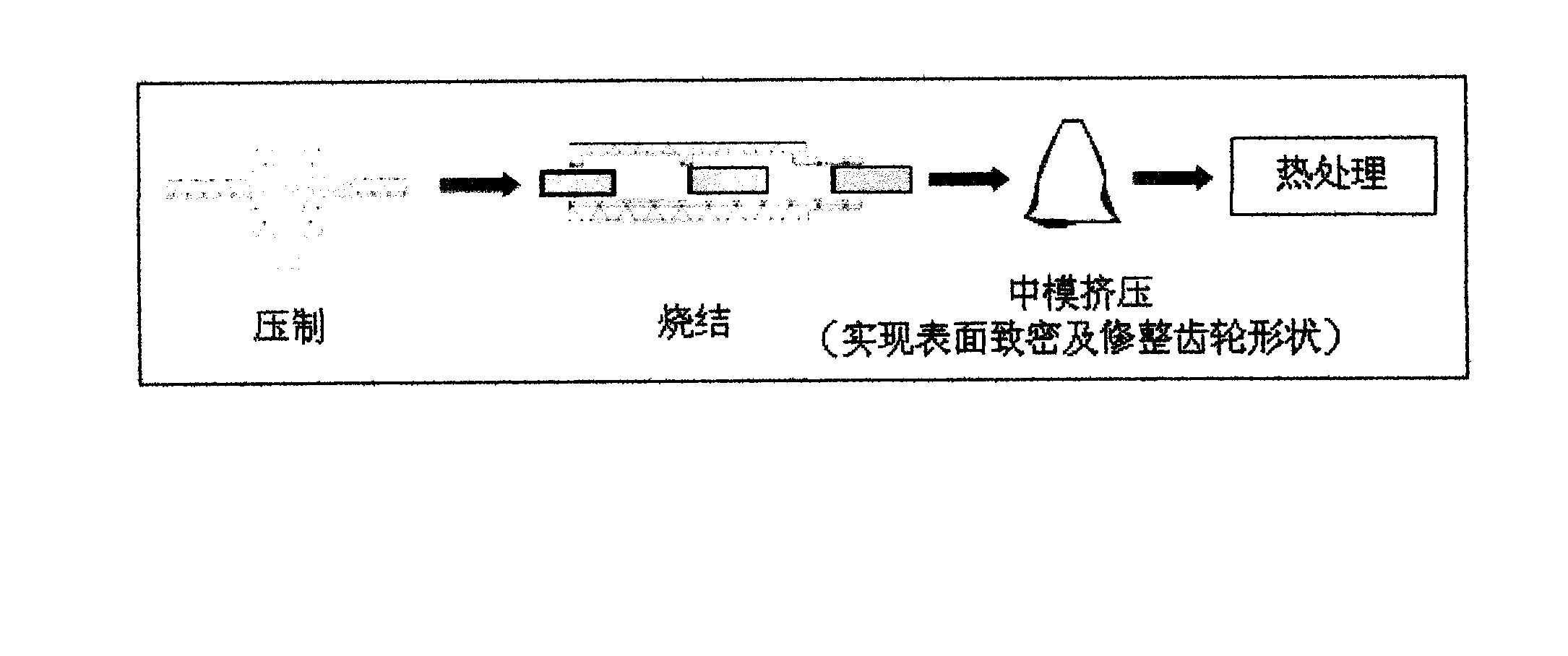

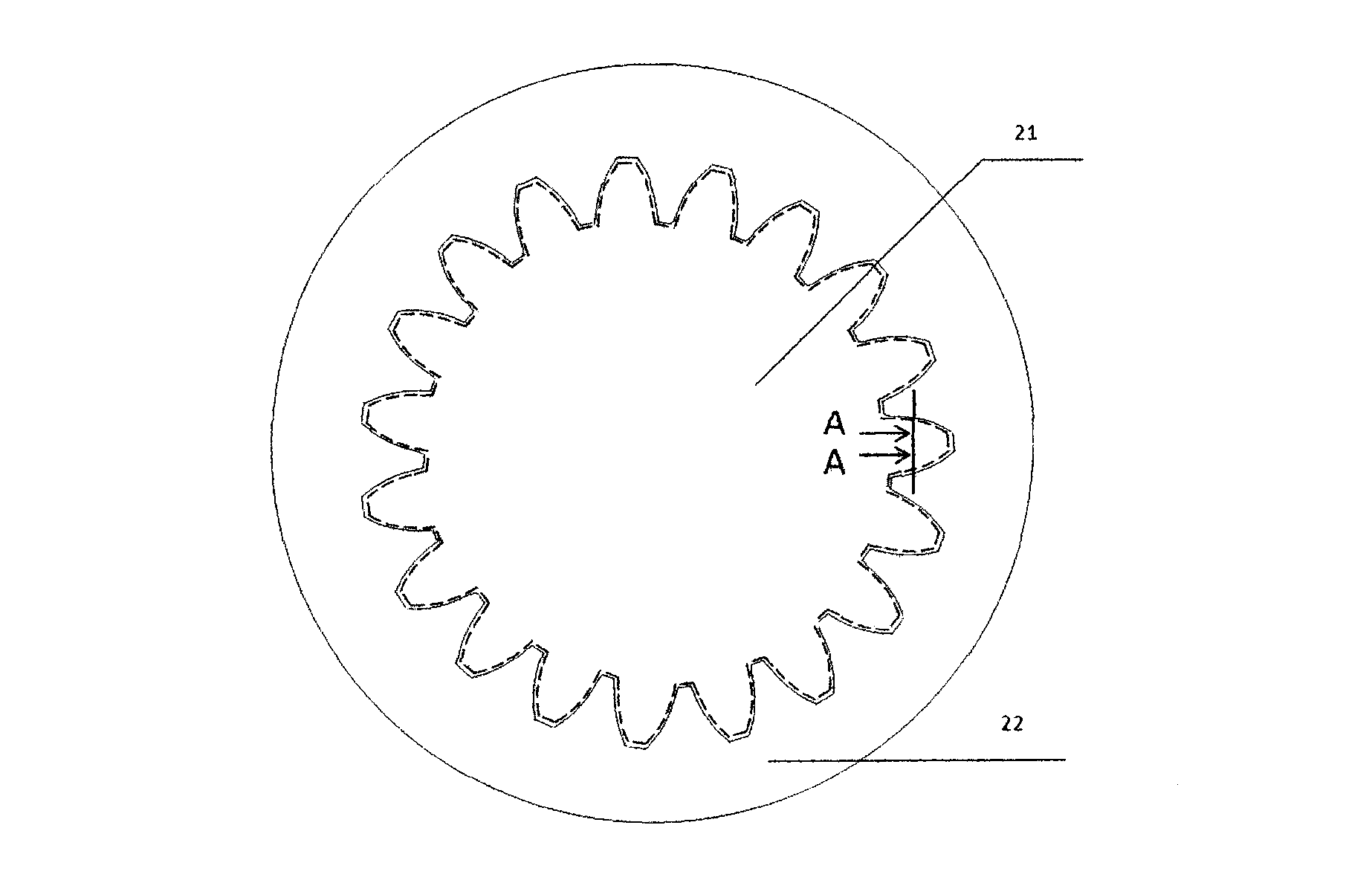

[0050] Combine below Figure 5 to Figure 9 , the present invention is further described:

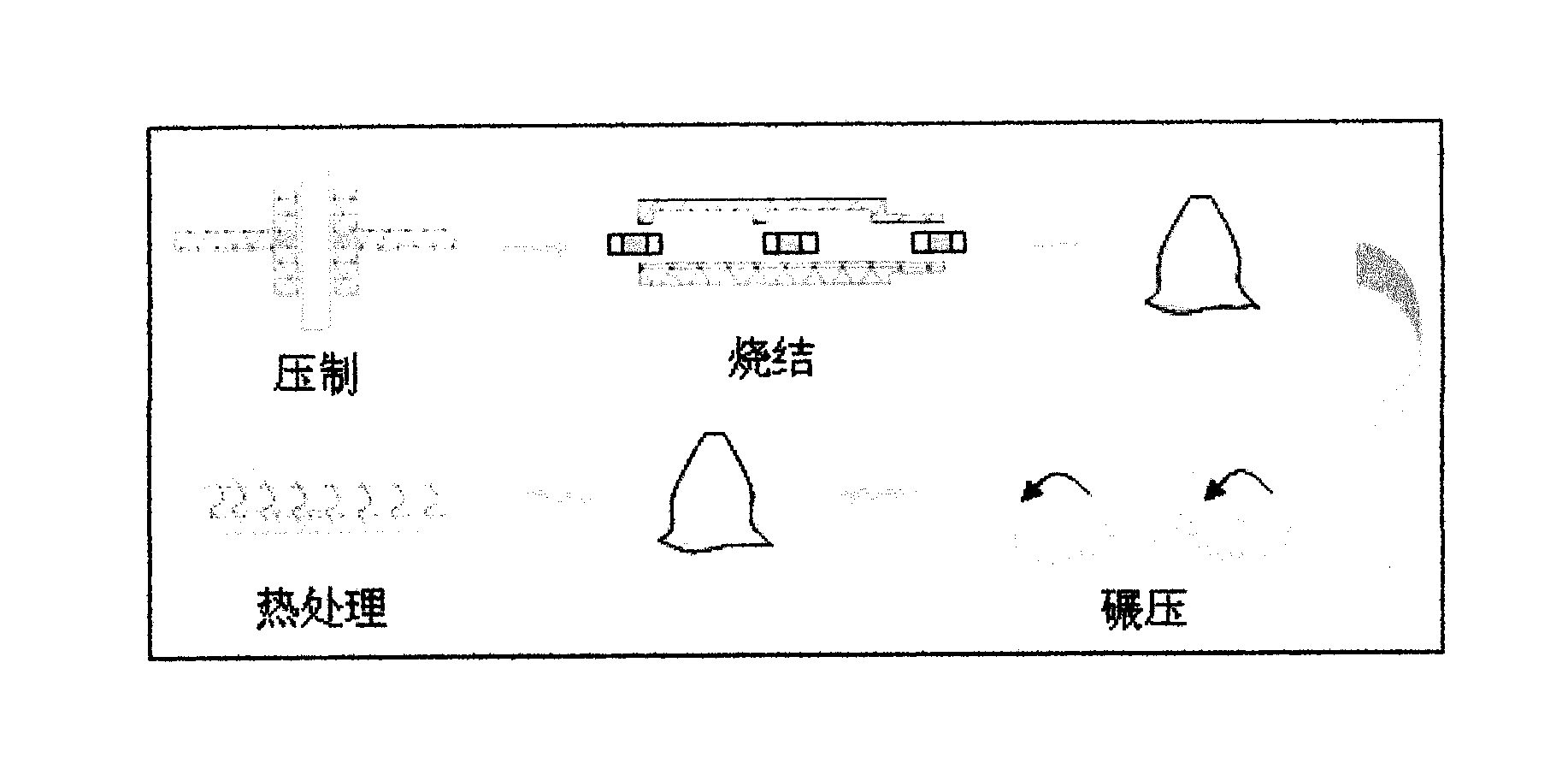

[0051] as attached Figure 5 As shown, the powder metallurgy surface dense gear production process flow of the patent of the present invention is as follows:

[0052] Step 10, mixing ingredients.

[0053] The purpose of mixing is to make the components of the powder mixture and between the powder and the lubricant evenly mixed to achieve the maximum bulk density.

[0054] Step 20, powder pressing.

[0055] Powder compaction is also called powder forming. The purpose is to compress the loose powder into a preform (also known as a green body) with a certain strength and a geometric shape close to the final product.

[0056] In order to form the green body, the mold needs to be filled with powder 2.0-2.5 times the height of the gear. For example, a 10mm high spur gear needs to be filled with 20-25mm high powder for pressing.

[0057] Step 30, sintering.

[0058] The early stage of si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com