Converter steelmaking endpoint determination method and system, control method and control system

A converter steelmaking and end point judgment technology, applied in the direction of manufacturing converters, etc., can solve the problems of low end point hit rate, hit rate can not meet the needs of automatic steelmaking, high price, etc., to improve the level of automation, shorten the smelting time, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

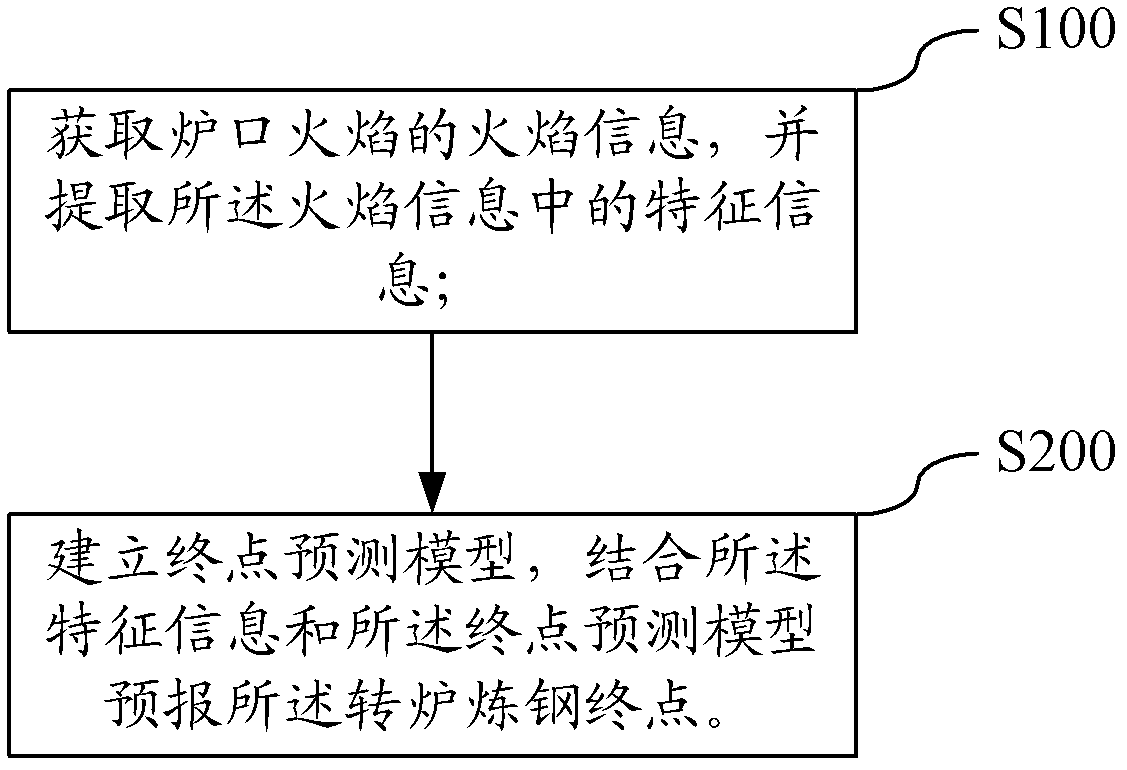

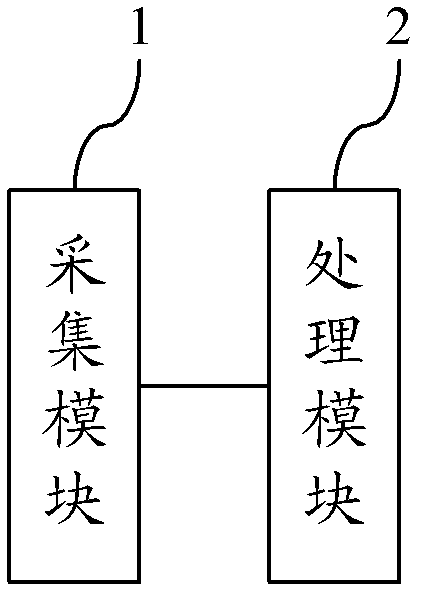

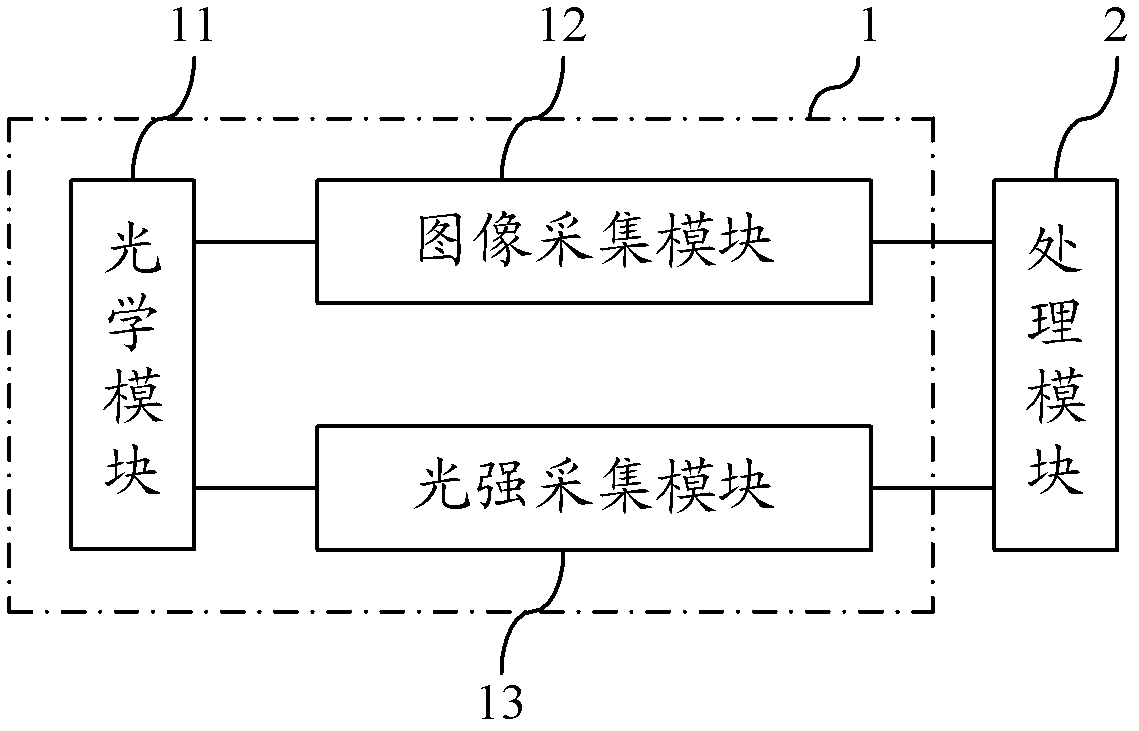

[0040] In the converter steelmaking, the furnace mouth flame is a sign of the temperature condition of the molten pool. The length and strength of the furnace mouth flame and the amount of the furnace mouth spark are an important basis for judging the carbon content of the molten steel.

[0041] The carbon-oxygen reaction in each stage of the conversion has different characteristics, generally the initial reaction is gentle (the soot contains more oxygen and other impurities), the middle-term reaction is intense (mainly the combustion of oxygen and carbon monoxide), and the final reaction is gentle and soft (carbon Less content reflects tending to end). At the same time, both the light intensity and the image of the furnace mouth flame will show a certain regular change. In particular, this regular change will become very obvious due to the reduction of carbon content at the end of the blowing. Therefore, the converter smelting process can be monitored by processing and research...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com