Preparation method for distillate aromatic extract (DAE)

A technology for aromatic rubber oil and raw oil, applied in the direction of refined hydrocarbon oil, petroleum industry, etc., can solve the problems that have not been raised, and achieve the effects of good selectivity, high extraction efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

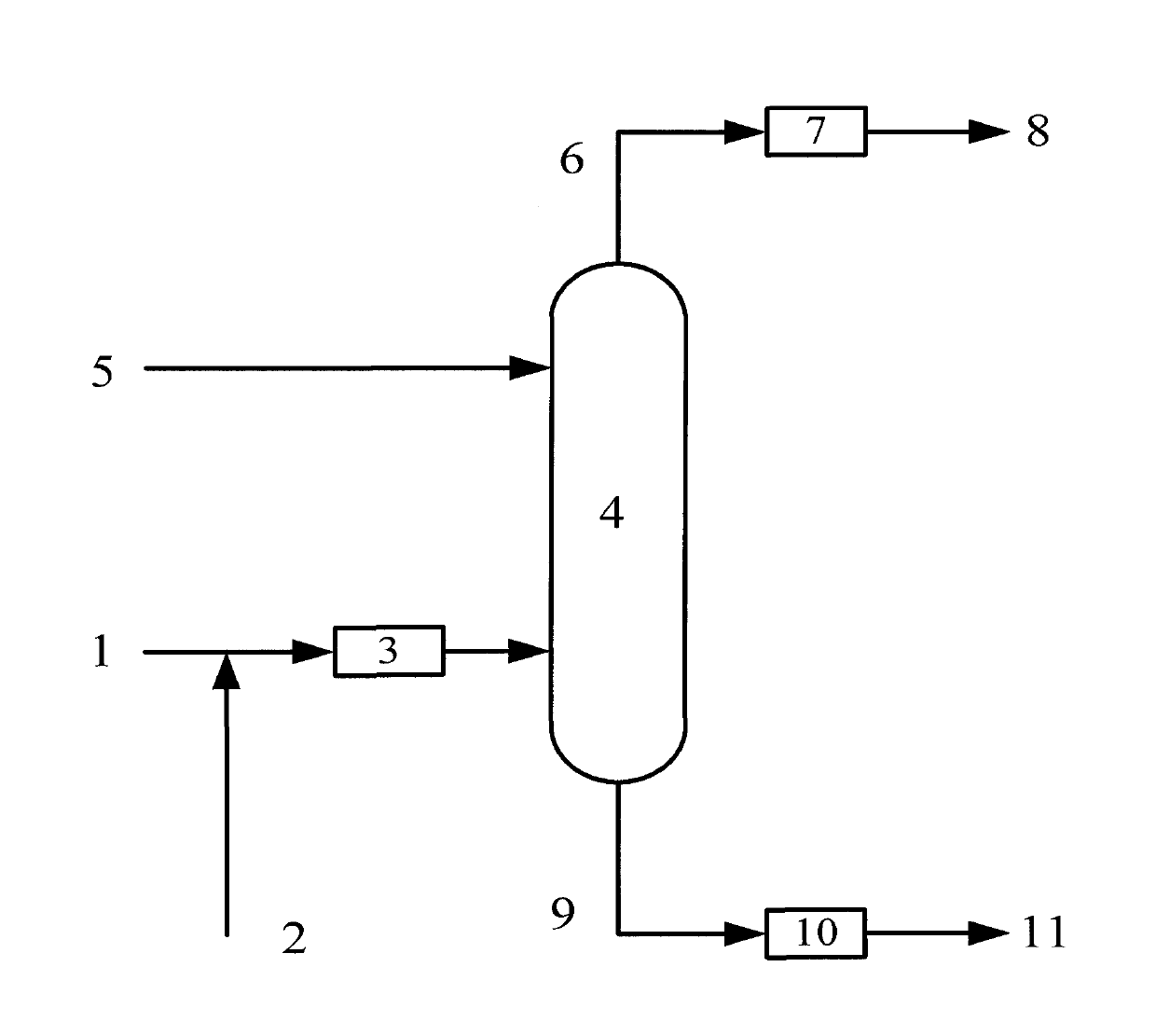

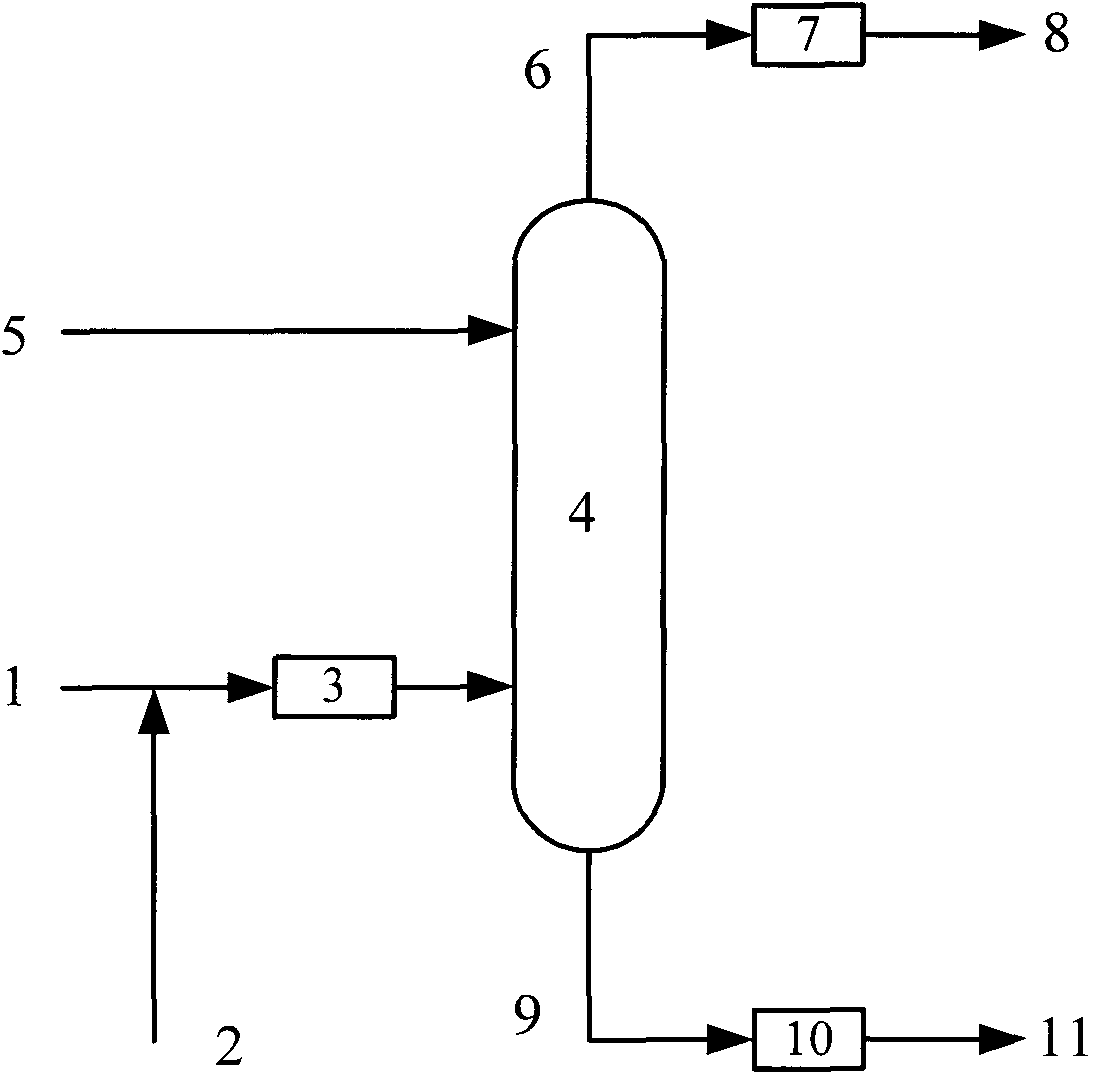

[0009] A preparation method of aromatic hydrocarbon rubber oil, comprising: after raw material oil is mixed with a diluent solvent, enters an extraction tower, contacts with the extraction solvent in the extraction tower, and separates the raffinate oil from the raffinate; the raw material oil Solvent refined extract oil and / or dewaxed oil of solvent refined extract oil, the dilution solvent contains a main solvent, the extraction solvent contains a main solvent and an anti-solvent, and the solubility of the main solvent to aromatics is greater than that to alkanes Solubility.

[0010] The solvent-refined extracted oil refers to the extracted oil obtained by the solvent-refined process. The solvent-refined extracted oil includes one or more of the extracted oils obtained from the following crude oil fractions through solvent refining process: second-line distillate oil, third-line distillate oil, fourth-line distillate oil, fifth-line distillate oil and solvent Deasphalted oi...

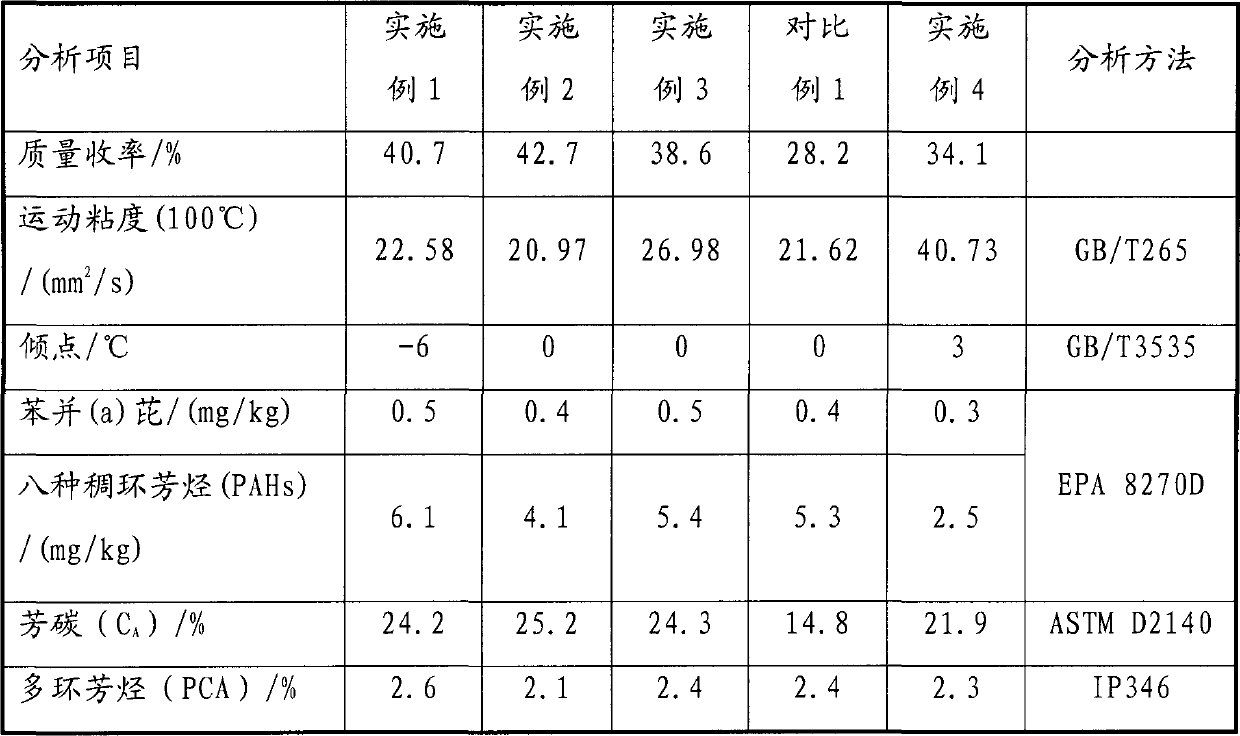

Embodiment 1

[0035] The solvent-refined oil extracted from naphthenic crude oil minus the second-line distillate oil is used as raw material, and its properties are shown in Table 1. Extraction is carried out in a packed extraction tower (tower size Φ42×4000×3.5) with three theoretical extraction stages. The total feed flow of solvent and raw oil to the extraction column is 4200 g / h.

[0036] Carry out solvent extraction according to accompanying drawing 1 flow process, prepare aromatic hydrocarbon rubber oil. The extraction conditions are: the temperature at the top of the extraction tower is 55°C, the temperature at the bottom of the tower is 45°C, the mass ratio of the dilution solvent to the raw oil is 0.2:1, after being mixed by the mixer 3, it enters the bottom of the extraction tower, and is mixed with the The extraction solvent entering the upper part of the extraction tower is in countercurrent contact, and the mass ratio of the extraction solvent entering the upper part of the ex...

Embodiment 2

[0038] Solvent extraction was carried out on the same extraction device as in Example 1 to prepare aromatic rubber oil, and the extracted oil obtained by subtracting third-line distillate oil from intermediate base crude oil through solvent dewaxing and then solvent refining was used as raw material, and its properties are shown in Table 1.

[0039] Carry out solvent extraction according to accompanying drawing 1 flow process, prepare aromatic hydrocarbon rubber oil. The extraction conditions are: the temperature at the top of the extraction tower is 65°C, the temperature at the bottom of the tower is 50°C, the mass ratio of the dilution solvent to the raw oil is 0.1:1, after being mixed by the mixer 3, it enters the lower part of the extraction tower, and is mixed with the The extraction solvent entering the upper part of the extraction tower is in countercurrent contact, and the mass ratio of the extraction solvent entering the upper part of the extraction tower to the raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com