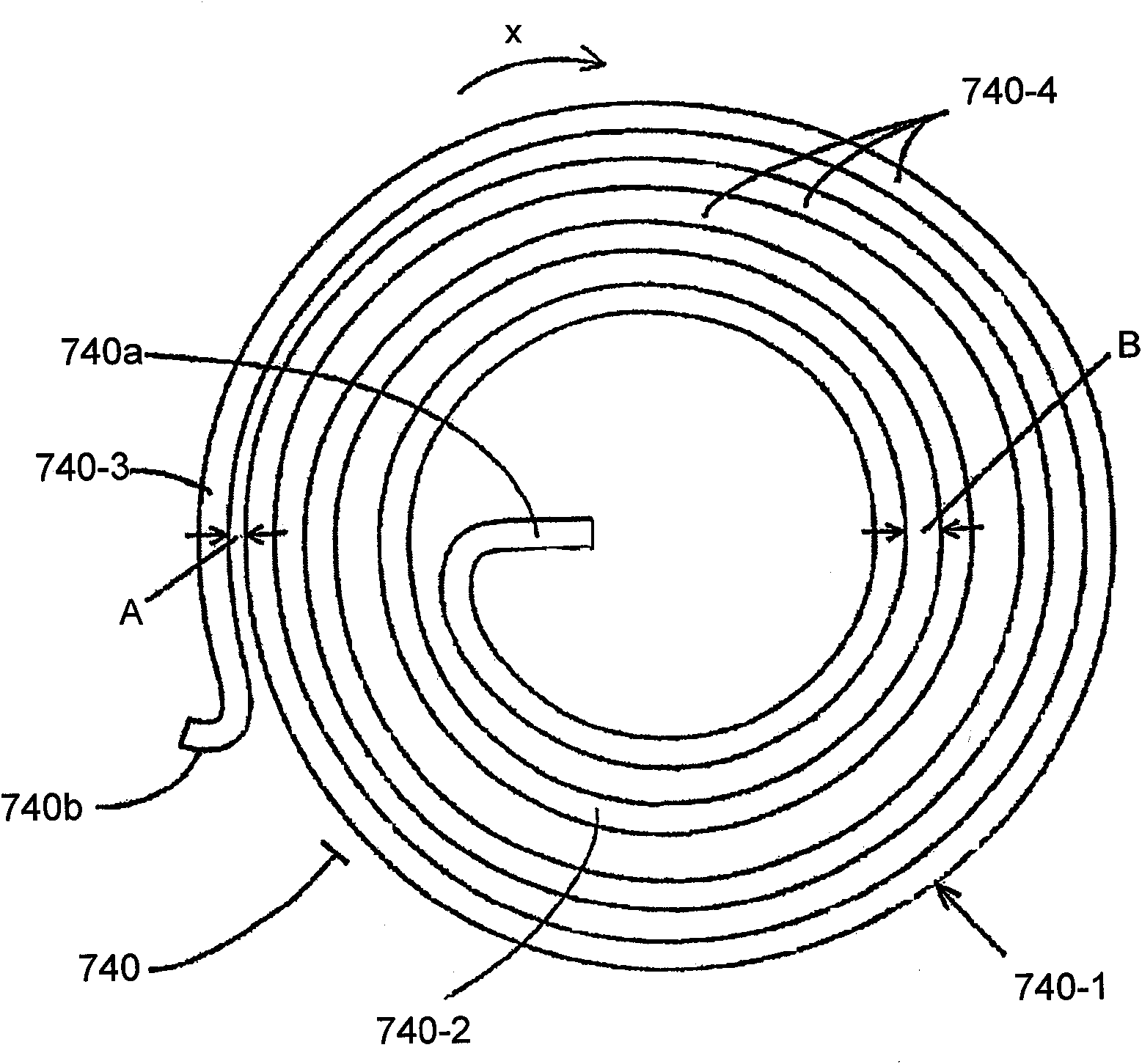

Spiral spring

A coil spring, reed technology, applied in the direction of coil springs, springs/shock absorbers, chairs, etc., can solve the problems that do not involve spring and/or reclining adjustment mechanism, do not fully explain the pitch coil structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

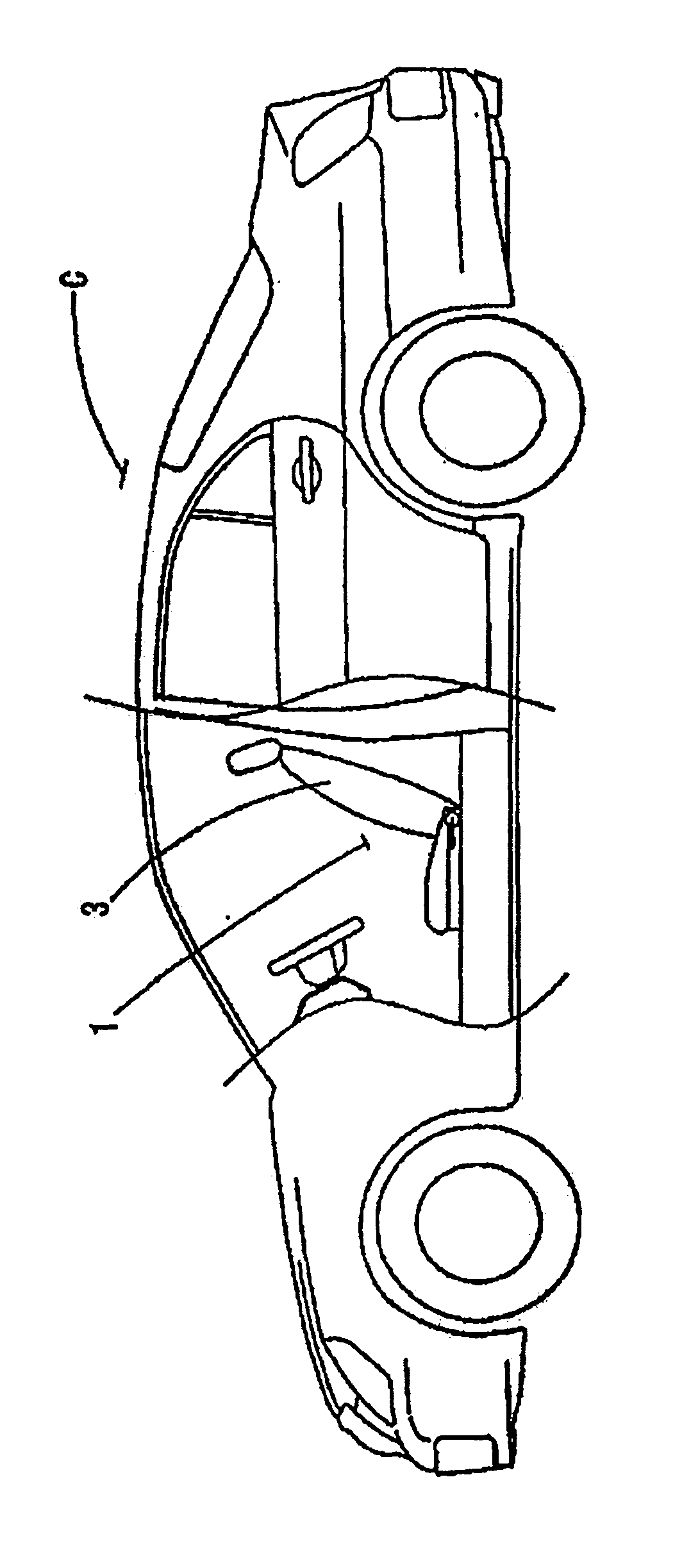

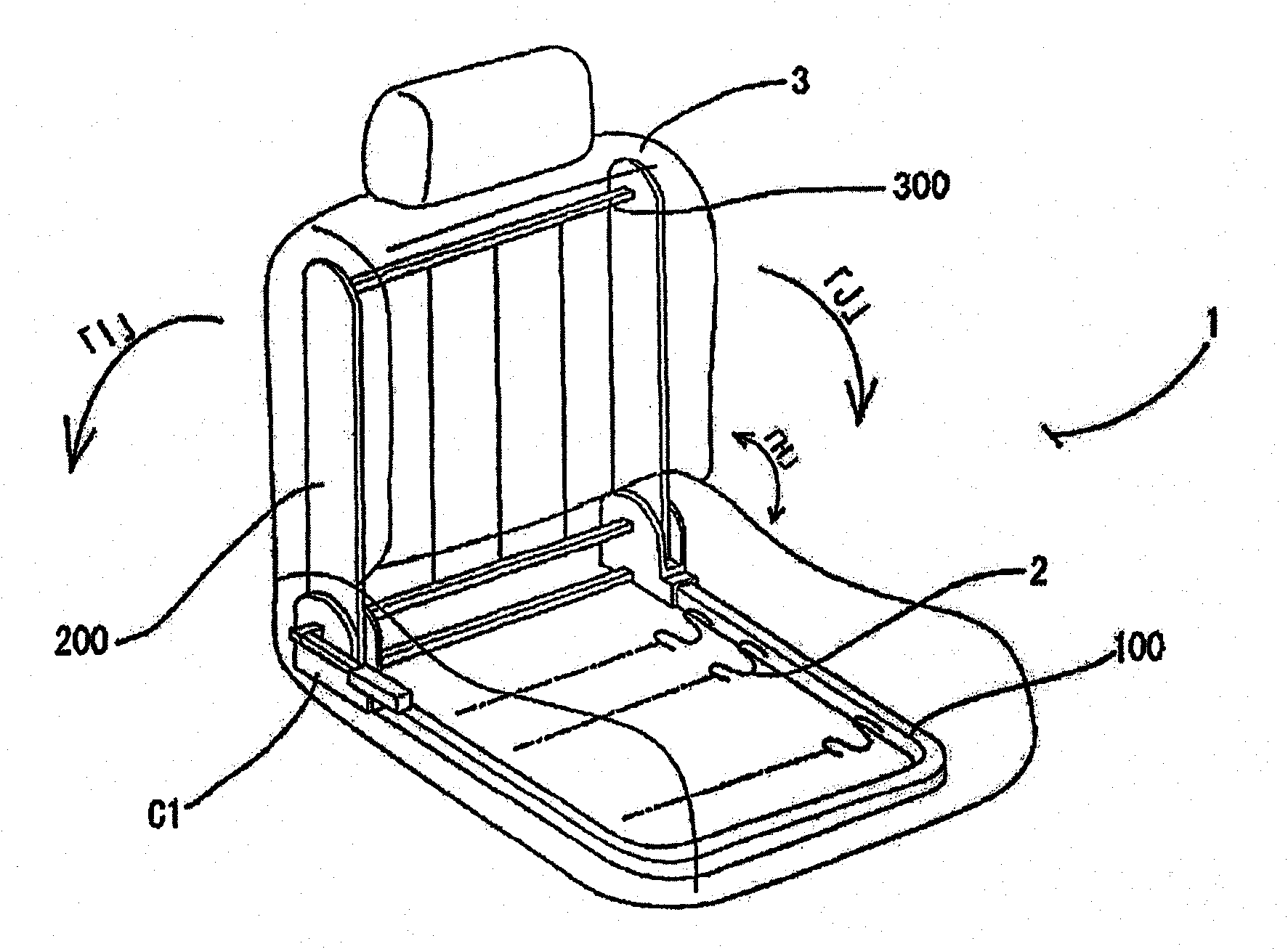

[0048] When describing the first embodiment, 1 in the figure is the first seat of the vehicle C, and the first seat 1 is mainly composed of a bottom frame 100 mounted on the floor and a pair of upper arms 200 mounted on the rear end side of the bottom frame 100. . Also, the bottom frame 100 is configured in the form of a rectangular frame in which a spring-like cushion frame 2 is installed. There is also a structure covered with polyurethane pads (not shown) and wool thick woolen seat pads (not shown) above the cushion frame 2 . The lower ends of the upper arms 200 , 200 (referred to as 200 ) are respectively attached to the left and right rear ends (in the forward direction) of the bottom frame 100 so as to be movable in the front-rear direction (arrow H). In addition, upper ends of the respective upper arms 200 are coupled to each other by a link 300 having a length approximately equal to the left and right width of the bottom frame 100 , whereby the left and right upper ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com