Non-aqueous electrolyte secondary battery and fabrication method for non-aqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in non-aqueous electrolyte battery electrodes, non-aqueous electrolyte batteries, electrolyte battery manufacturing and other directions, can solve the problems of inability to suppress micronization, reduction in current collection, volume expansion and contraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

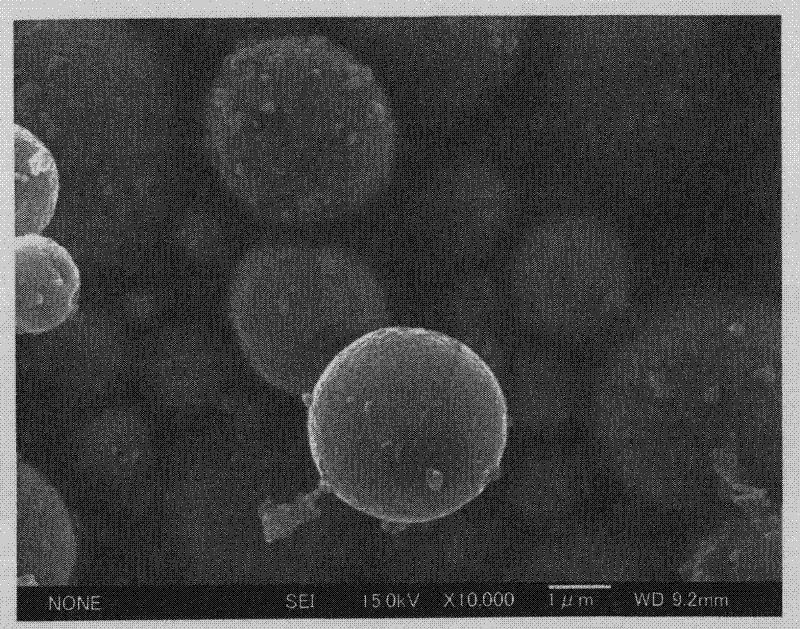

[0093] In Example 1, as the negative electrode active material, the first active material used was produced by the atomization method, with an average particle diameter of 4.5 μm and spherical zinc (Kishida Chemical Co., Ltd., special grade, product number 000- 87575, refer to figure 1 ), the second active material uses artificial graphite with an average particle diameter of 22 μm and a lattice constant of 0.3362 nm. In addition, the average particle diameter of zinc and artificial graphite was measured with SALAD-2000 by Shimadzu Corporation.

[0094] Then, the above-mentioned first active material and second active material were mixed by a ball mill at a mass ratio of 5:95. In addition, when mixing with a ball mill, 10 SUS balls with a diameter of 12.5 mm and 8.5 g were used, and the operation was repeated 60 times by mixing at 200 rpm for 30 seconds and then stopping for 30 seconds as one operation.

[0095] Then, add binder polyvinylidene fluoride and dispersion medium...

Embodiment 2

[0101] In Example 2, in the preparation of the negative electrode active material of the above-mentioned Example 1, only the mass ratio of the above-mentioned first active material composed of zinc and the above-mentioned second active material composed of artificial graphite is changed to 10:90, Make the negative electrode. Furthermore, a test battery of Example 2 was fabricated in the same manner as in Example 1 except for using the negative electrode.

Embodiment 3

[0103] In Example 3, in the preparation of the negative electrode active material of the above-mentioned Example 1, only the mass ratio of the above-mentioned first active material composed of zinc and the above-mentioned second active material composed of artificial graphite is changed to 30:70, Make the negative electrode. Furthermore, a test battery of Example 3 was fabricated in the same manner as in Example 1 except for using this negative electrode.

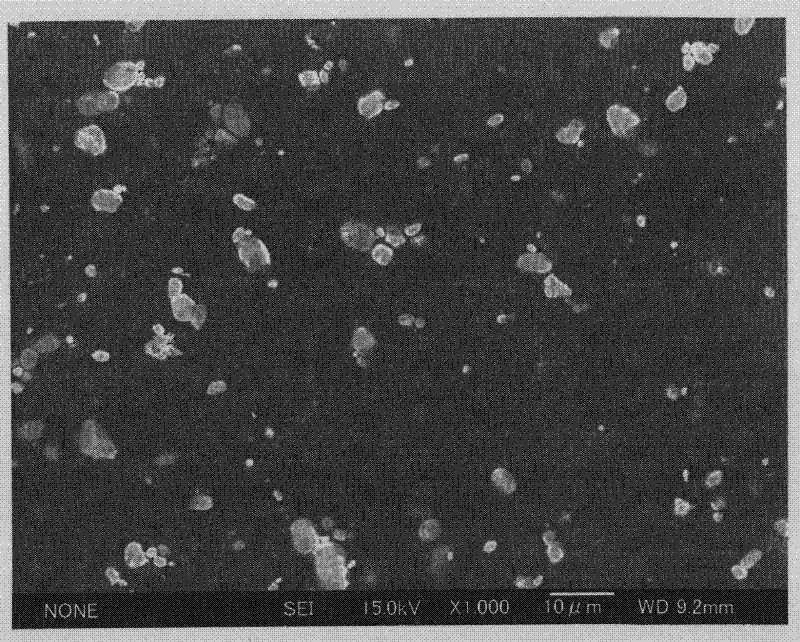

[0104] In addition, the surface of the negative electrode produced in Example 3 was observed by a scanning electron microscope (SEM), and the surface of the negative electrode was enlarged to 1000 times. The SEM image is as follows: image 3 As shown, the SEM image of the surface of the negative electrode magnified to 5000 times is as follows Figure 4 shown. As a result, such as image 3 As shown, the first active material composed of zinc exists in the state of being dispersed in the second active material composed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com