Multi-element standard solution for analyzing harmful elementary compositions in steel and preparation method of multi-element standard solution

A technology for the analysis of harmful elements and components, used in thermal excitation analysis, material excitation analysis, etc., can solve the problems of segregation and cracks, matrix matching and collective interference, complex analysis methods, etc., to achieve good economic and social benefits, reduce quality Objection, effect of shortening analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

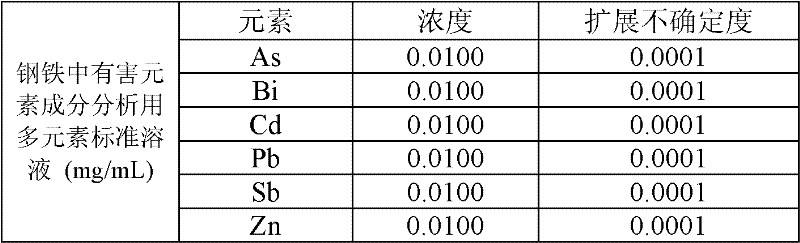

[0018] The elements contained in a multi-element standard solution for harmful element composition analysis in steel are: arsenic (As), antimony (Sb), bismuth (Bi), lead (Pb), zinc (Zn), cadmium (Cd);

[0019] The content of each element is shown in Table 1.

[0020] Table 1 The content of each element in the multi-element standard solution for the analysis of harmful elements in steel

[0021]

[0022] A method for preparing a multi-element standard solution for harmful element composition analysis in steel, comprising the following steps,

[0023] (1). Establish a laboratory with a constant temperature of 20°C, a humidity control of 70% to 80%, and a cleanliness of 10,000, and a test bench with a cleanliness of 100;

[0024] (2). Weigh respectively 0.4000g of high-purity lead with a purity of 99.99%, high-purity cadmium with a purity of 99.999%, high-purity zinc with a purity of 99.999%, and high-purity bismuth with a purity of 99.99% in a beaker, and add 5mL Nitric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com