Pesticide residue detection powder and preparation method, cuvette and detection method

A technology for pesticide residue detection and cuvettes, which is applied to measurement devices, material analysis, instruments and other directions by observing the impact on chemical indicators, can solve the problem of long detection time, no relevant improvements and optimizations, and detection operations. Irregularities and other problems, to achieve the effect of simplifying operation steps, avoiding irregularities, and facilitating standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

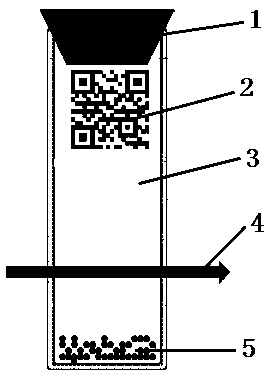

[0022] Take a standard 4.5mL cuvette made of methacrylate, accurately measure 100μL of acetylcholinesterase solution, and 100μL of chromogenic reagent into the cuvette, add 300μL of polyethylene glycol protective agent, and place it in a freeze-drying box ,

[0023] The freeze-drying process is set as follows: the temperature of the cold trap is set to -40°C, the vacuum is turned on, when the vacuum degree reaches 15Pa, hold for 2 hours, set the heating program to heat to -20°C, and keep the final temperature for 2 hours, let the sample sublime naturally , the sublimation drying time is set to 10 hours. After the freeze-drying is completed, the cuvette is sealed, and the QR code is engraved. In this way, the enzyme-chromogen lyophilized powder containing 300uL polyethylene glycol is prepared, and the prepared sample is placed in an environment of 2-8 °C. to save. After the prepared reagent is returned to room temperature, it can be directly used for the detection of pesticid...

Embodiment 2

[0033]Take a standard 4.5mL cuvette made of methacrylate, accurately measure 100μL of acetylcholinesterase solution, and 100μL of color developer into the cuvette, add 500μL of polyethylene glycol protective agent, and place in a freeze-drying box The freeze-drying process is set as follows: the temperature of the cold trap is set to -40°C, the vacuum is turned on, when the vacuum degree reaches 15Pa, it is kept for 2 hours, the heating program is set to heat to -20°C, and the final temperature is kept for 2 hours, the sample is Natural sublimation, sublimation drying time is set to 10 hours. After the freeze-drying is completed, the cuvette is sealed, and the two-dimensional code is engraved, so that the preparation of the enzyme-chromogenic agent freeze-dried powder is completed, and the prepared sample is stored in an environment of 2-8 °C. Make powder according to the above freeze-drying procedure. After sealing, the two-dimensional code is burnt. In this way, the preparat...

Embodiment 3

[0035] Take a standard 4.5mL cuvette made of methacrylate, accurately measure 100μL of acetylcholinesterase solution, and 100μL of chromogenic reagent into the cuvette, add 1000μL of polyethylene glycol protective agent, and place in a freeze-drying box The freeze-drying process is set as follows: the temperature of the cold trap is set to -40°C, the vacuum is turned on, when the vacuum degree reaches 15Pa, it is kept for 2 hours, the heating program is set to heat to -20°C, and the final temperature is kept for 2 hours, the sample is Natural sublimation, sublimation drying time is set to 10 hours. After the freeze-drying is completed, the cuvette is sealed, and the two-dimensional code is engraved, so that the preparation of the enzyme-chromogenic agent freeze-dried powder is completed, and the prepared sample is stored in an environment of 2-8 °C. According to the above freeze-drying procedure, the powder is prepared. After sealing, the two-dimensional code is inscribed. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com