Method for separation and extraction of active peptide from domestic fungus by-products

A separation method and edible fungus technology, applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of lack of pertinence, difficulty in separation, low purity, etc., and achieve improved utilization rate, simple process, and hydrolysis time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

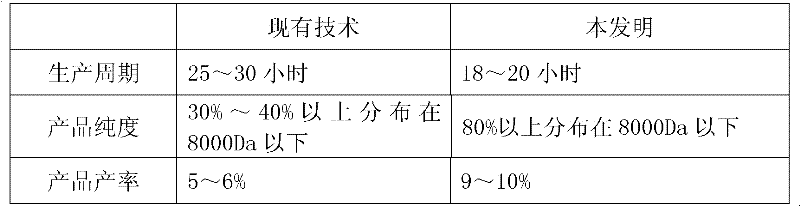

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Wash it with Flammulina velutipes, mash it, and grind it into a paste, so that the weight ratio of water and material is 1:15, the pH value is adjusted to 9, and the temperature is 50°C. Add alkaline protease, papain, and trypsin in a weight ratio of 1 : 1:1, the concentration weight ratio of the substrate material to the compound enzyme is 3%, after the enzymolysis time is 3 hours, the enzymolysis solution is heated to 90°C, kept for 20min, the enzyme is extinguished, and the enzymolysis solution is centrifuged at the same time; The liquid is pre-filtered through a plate and frame filter, and the filter material is nylon filter cloth; the coarse filtrate is fine-filtered through a cellulose acetate organic membrane with a cut-off particle size of 0.1 μm, and the filtration pressure is 0.15 MPa; Amide organic composite membrane ultrafiltration, filtration pressure 0.2MPa, cut off and harvest peptide solution with molecular weight less than 8000Da; peptide solution vacuum...

Embodiment 2

[0039] Wash it with shiitake mushrooms, smash them, and grind them into a paste, so that the weight ratio of water and materials is 1:12, the pH value is adjusted to 7, and the temperature is 35°C. Add alkaline protease, papain, and trypsin in a weight ratio of 1 : 1:1, the concentration weight ratio of the substrate material to the compound enzyme is 3%, after the enzymolysis time is 4 hours, the enzymolysis solution is heated to 85°C, kept for 18min, the enzyme is extinguished, and the enzymolysis solution is centrifuged at the same time; The liquid is pre-filtered through a plate and frame filter, and the filter material is nylon filter cloth; the coarse filtrate is fine-filtered through a cellulose acetate organic membrane with a cut-off particle size of 0.2 μm, and the filtration pressure is 0.2 MPa; the fine filtrate is then passed through an aromatic polyamide with a molecular weight cut-off of 6000Da Organic composite membrane ultrafiltration, filtration pressure 0.25MP...

Embodiment 3

[0041] Wash it with Flammulina velutipes, mash it, and grind it into a paste, so that the weight ratio of water and material is 1:12, the pH value is adjusted to 8, and the temperature is 55°C. Add alkaline protease, papain, and trypsin in a weight ratio of 1 : 1:1, the weight ratio of the substrate material to the compound enzyme is 3%, after the enzymolysis time is 5 hours, the enzymolysis solution is heated to 80°C, kept for 15min, the enzyme is extinguished, and the enzymolysis solution is centrifuged at the same time; the enzymolysis solution is taken After primary filtration by plate and frame filter, the filter material is nylon filter cloth; the coarse filtrate is finely filtered by cellulose acetate organic membrane with a cut-off particle size of 0.15 μm, and the filtration pressure is 0.2 MPa; the fine filtrate is then passed through an aromatic polyamide with a molecular weight cut-off of 6000Da Organic composite membrane ultrafiltration, filtration pressure 0.15MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com