Method for purifying and recycling feed liquid from erythromycin produced by fermentation method

A technology of erythromycin and fermentation method is applied in the field of purifying and recycling fermentation method to produce erythromycin feed liquid, which can solve the problems of environmental protection, resource waste, waste and the like that are not fundamentally solved, and achieves convenient operation and resource saving. , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

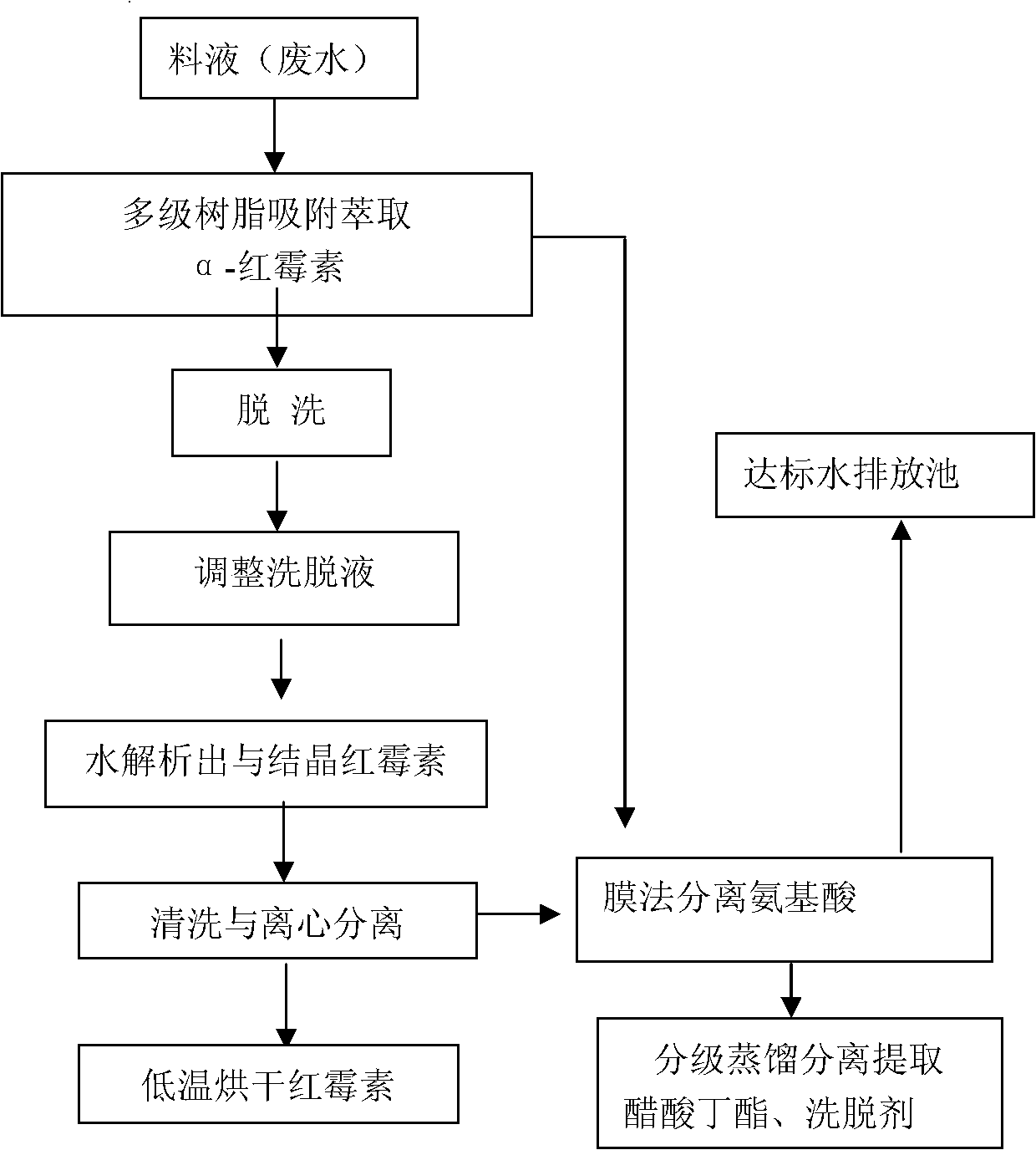

Image

Examples

Embodiment 1

[0017] Example 1 A method for purifying and recycling erythromycin feed liquid by fermentation, characterized in that: XDA-1 resin is used to absorb α-erythromycin in the feed liquid, and acetone is added to analytically pure acetone After the eluent eluting described resin of volume 15% distilled water preparation, the pH value of adjusting eluent is 8 and the water content of adjusting eluent is 18%wt, then adjusts the pH value of eluent to 9.5, will The eluate was heated to 45°C and kept for 3 hours to precipitate and crystallize erythromycin. Finally, it was washed with 50°C distilled water and centrifuged, and the solid obtained by centrifugation was dried in a vacuum dryer at 50°C to obtain erythromycin Prime alkali.

[0018] In view of the purity and hygienic requirements of the product, the extraction wastewater from the production of erythromycin by fermentation is transported from the extraction process (extraction tank) of the pharmaceutical factory to the feed li...

Embodiment 2

[0019] Example 2 A method for purifying and recycling erythromycin feed liquid by fermentation, characterized in that: D-4020 resin is used to absorb α-erythromycin in the feed liquid, and acetone is added to analytically pure acetone After the eluent eluting described resin of volume 10% distilled water preparation, adjust the pH value of eluent at 7 and adjust the water content of eluent at 15%wt, then adjust the pH value of eluent to 9, will The eluate is heated to 50°C and kept for 2 hours to precipitate and crystallize erythromycin, and finally to perform secondary washing and centrifugation with 50°C distilled water, and dry the solid obtained by centrifugation at no higher than 50°C to obtain erythromycin alkali.

[0020] In view of the purity and hygienic requirements of the product, the extraction wastewater from the production of erythromycin by fermentation is transported from the extraction process (extraction tank) of the pharmaceutical factory to the feed liqui...

Embodiment 3

[0021] Example 3 A method for purifying and recycling erythromycin feed liquid by fermentation, characterized in that: D-1300 resin is used to absorb α-erythromycin in the feed liquid, and acetone is added to analytically pure acetone After the eluent eluting described resin of volume 20% distilled water preparation, adjust the pH value of eluent at 10 and adjust the water content of eluent at 20%wt, then adjust the pH value of eluent to 10.5, will The eluate is heated to 40°C and kept for 4 hours to precipitate and crystallize erythromycin. Finally, it is washed with 50°C distilled water and centrifuged, and the solid obtained by centrifugation is dried in a vacuum dryer at no higher than 50°C to obtain Erythromycin base.

[0022] In view of the purity and hygienic requirements of the product, the extraction wastewater from the production of erythromycin by fermentation is transported from the extraction process (extraction tank) of the pharmaceutical factory to the feed li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com