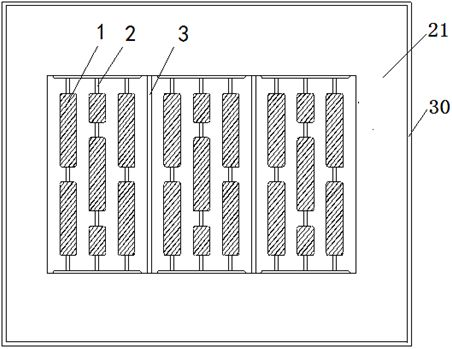

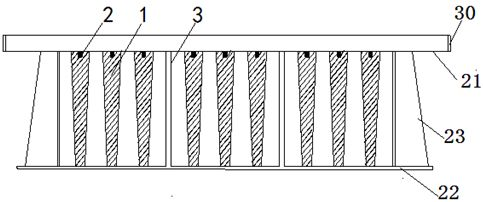

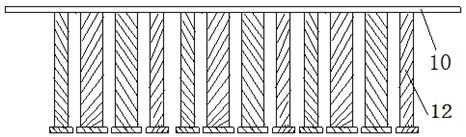

Die for production of three-row-hole recycled concrete

A technology of recycled concrete and blocks, which is applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., and can solve the problems of large hollow rate, low utilization rate of recycled aggregates, and few rows of mold holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The use of construction waste to produce recycled concrete blocks, due to the nature of the recycled concrete itself, is directly produced with ordinary concrete block molds, and the strength of the recycled concrete blocks produced is not high, which limits the application range of recycled concrete blocks. The applicant found through experimental research and analysis that the main reason is that ordinary concrete blocks have fewer holes in the mold, the hollow ratio is larger, and the mold compression ratio is relatively large. It is directly used to produce recycled concrete blocks, which cannot reach the compressive strength level of load-bearing blocks. requirements. In order to solve the above technical problems, the applicant optimized the mold structure on the basis of a large number of research experiments and continuous improvement, and finally determined the mold structure suitable for the production of three-row hole recycled concrete blocks for load-bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com