Gear shaping machine tool for teaching

A machine tool and gear technology, applied in the field of mechanical teaching experimental devices, can solve problems such as poor visibility, inconvenience in classroom teaching, complex gear shaping machine tool transmission systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

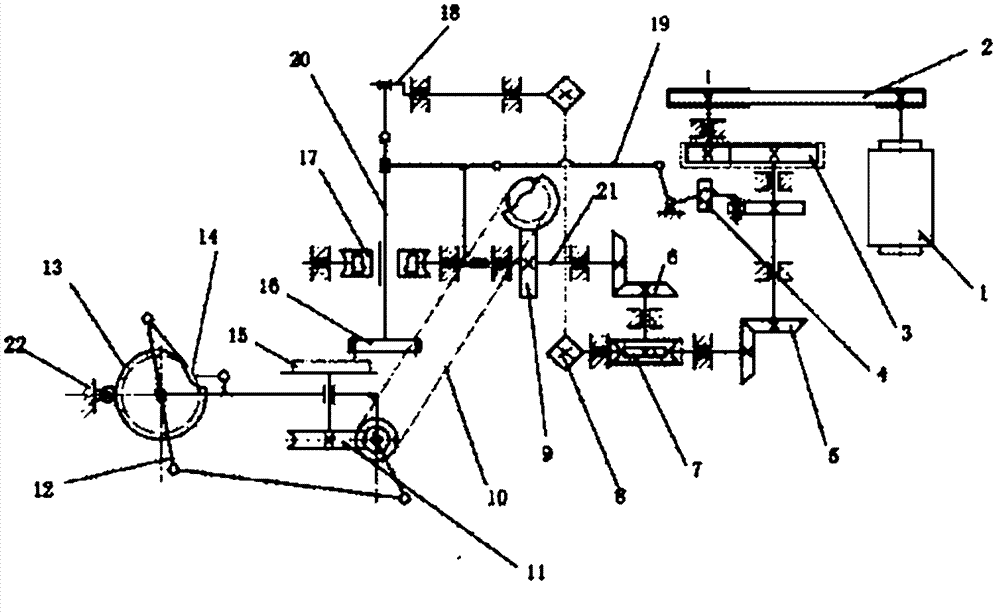

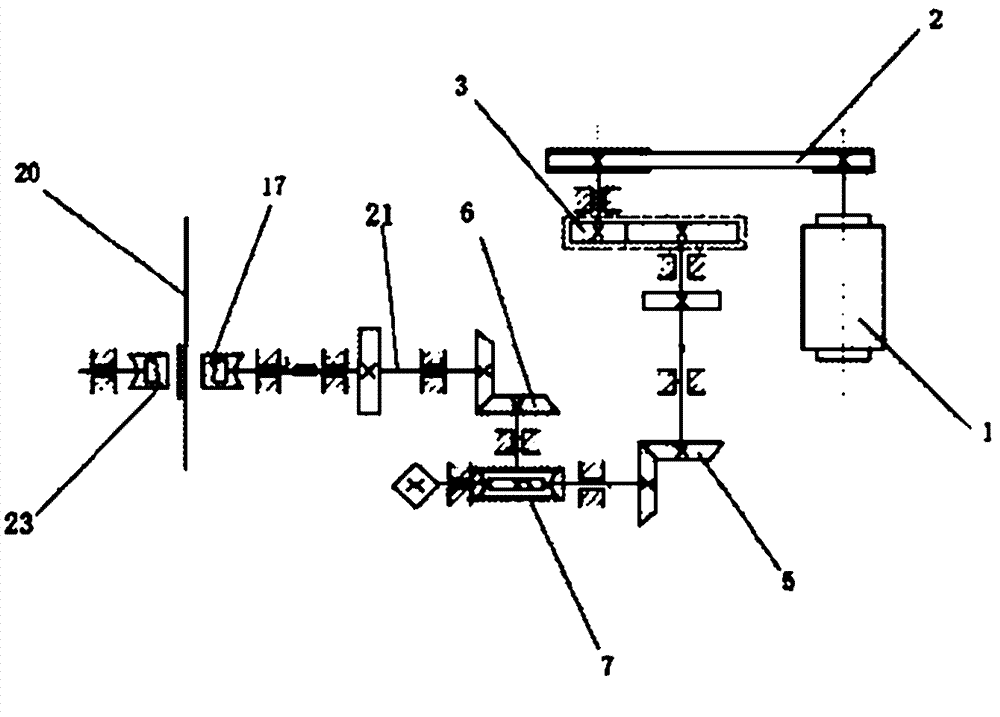

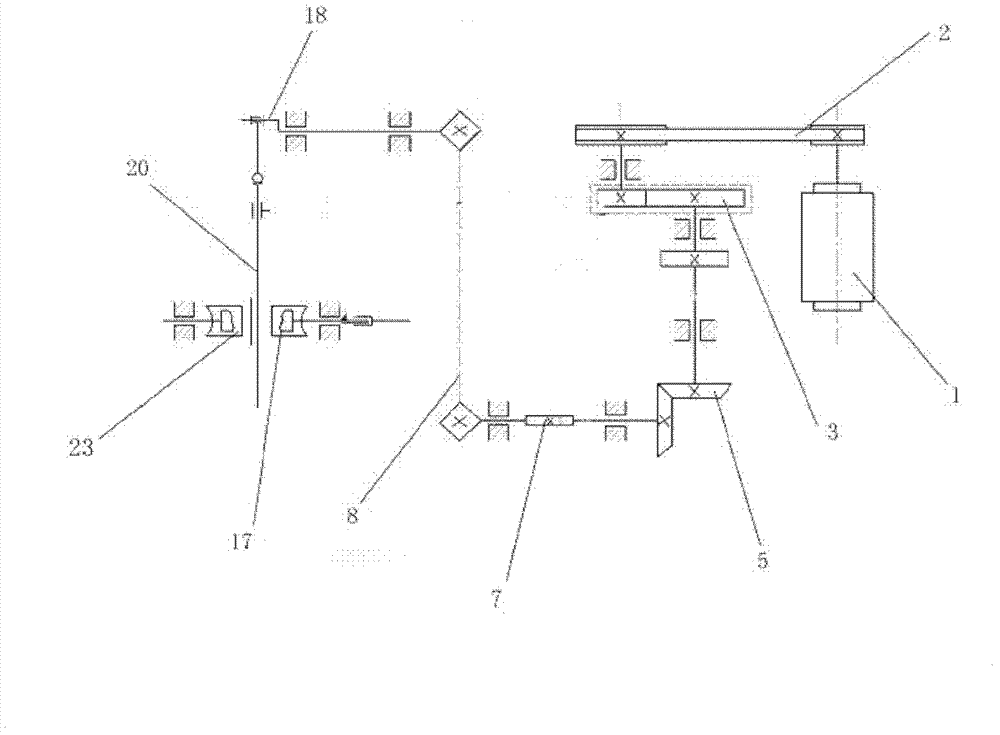

[0022] See attached Figure 1~6 , a gear shaping machine tool for teaching, comprising a frame 22, a motor 1, a gear reducer 3, a worm gear reducer 7, a tool spindle 20, and a workpiece turntable 15; the motor 1 is arranged on the frame 22, through The belt transmission 2 outputs power to the gear reducer 3, and the output shaft of the gear reducer 3 is connected to the input end of the worm gear reducer 7 through the first bevel gear pair 5 arranged thereon; see the attached Figure 4 The output shaft of the gear reducer 3 is also provided with a first cam mechanism 4, the first cam mechanism 4 is composed of a cam pair 28, and the output drive of the first cam mechanism 4 is connected to the connecting tool spindle 20 at one end. Rod 19, one end of the connecting rod 19 is connected to the first cam mechanism 4, and the other end is sleeved on the tool spindle 20, and the first cam mechanism 4 drives the connecting rod 19 to reciprocate, pulling the tool spindle 20 perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com