Bulk cargo top flattening device

A technology of flat top and cargo, which is applied in the field of bulk cargo flat top, which can solve the problems of low work efficiency, dust contained in goods, large dust, etc., and achieve the effect of improving work efficiency, ensuring flat top effect, and avoiding dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

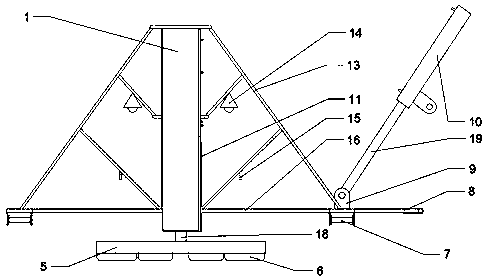

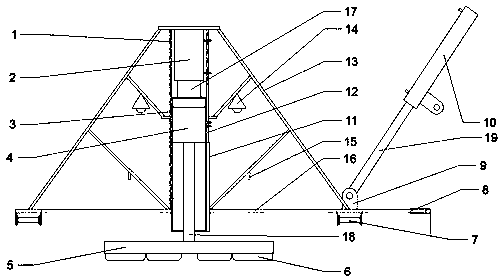

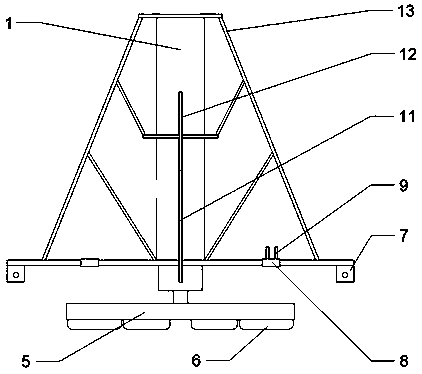

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] like figure 1 , 2 , 3, and 4 show a kind of bulk cargo leveling device, including an outer telescopic cylinder 1, a hydraulic cylinder A2, an inner telescopic cylinder 3, a hydraulic motor 4, and a flat top head 5, and the hydraulic cylinder A2 is fixed on the inner top of the outer telescopic cylinder 1 , the inner telescopic cylinder 3 is movably socketed inside the outer telescopic cylinder 1, and the top of the inner telescopic cylinder 3 is fixedly connected with the piston rod A17 of the hydraulic cylinder A2; The output end 18 of the motor 4 (JNG3_2300) is fixedly connected to the flat head 5; the lower surface of the flat head 5 is uniformly fixed with several scrapers 6; A connecting arm 8 is fixedly installed; the hydraulic cylinder A2 and the hydraulic motor 4 (JNG3_2300) are all connected to the hydraulic pump of the hydraulic power machine through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com