Engine starting system with high-and low-speed modes of motor operation

An engine starting and engine technology, which is applied to engine starting, engine motor starting, engine components, etc., can solve the problems of increasing the total production cost of the engine starting system, and achieve the effect of eliminating the need and improving the durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

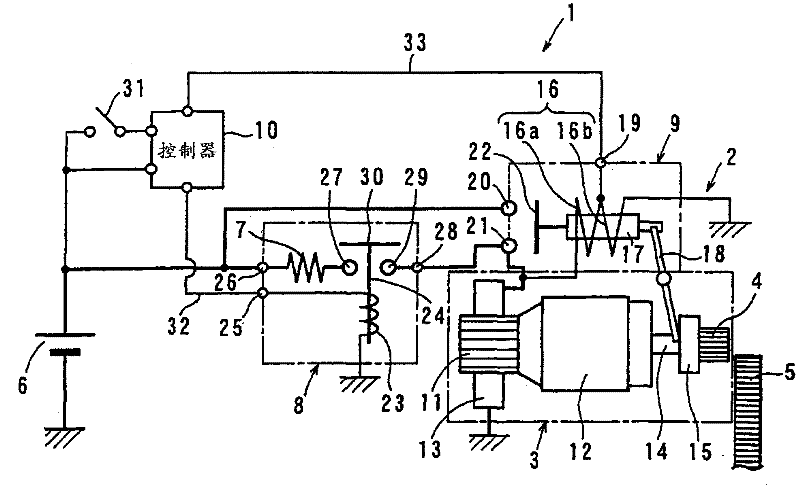

[0031] Referring to the drawings, wherein like reference numerals designate like parts throughout the several views, in particular figure 1 , shows an engine starting system 1 according to a first embodiment usable for a motor vehicle.

[0032]The engine starting system 1 includes a starter 2 , a resistor 7 , a motor relay 8 and a controller 10 . The starter 2 is equipped with an electric motor 3 that generates torque and transmits it to a ring gear 5 through a pinion 4 to start an internal combustion engine (not shown) installed in a motor vehicle. The ring gear 5 is mechanically coupled to the output shaft (ie, crankshaft) of the engine. The resistor 7 is used to reduce the current supplied from the battery 6 to the motor 3 through a motor circuit (described later in detail) when the motor 3 needs to be turned on. The motor relay 8 switches between electrical paths to supply current to the motor 3 after turning on the motor 3 bypassing the resistor 7 . The controller 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com