Method for degrading pectic polysaccharides with high efficiency

A pectin polysaccharide and high-efficiency technology, applied in the biological field, can solve the problems of low degradation efficiency, complexity, low oligosaccharide yield, etc., and achieve the effect of simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment the present invention is described in further detail:

[0025] The invention provides a method for efficiently degrading pectin polysaccharides, comprising the following steps:

[0026] 1. Dissolve 2 g of pectin in 0.5 mol / L trifluoroacetic acid (TFA) at a mass concentration of 1%, and acid hydrolyze it in a water bath at 80°C for 5 hours. volume of distilled water, fully shaken, centrifuged, and the supernatant and precipitate were collected and combined to obtain two components, the supernatant and the precipitate. The supernatant is 0.591g, the precipitate is 1.142g, and the yield can reach 86.65%, wherein the content of the precipitate is about twice that of the supernatant.

[0027] The supernatant fraction was detected by fluorescence-assisted carbohydrate electrophoresis (FACE), and the electrophoresis pattern showed that the supernatant fraction was also a pectin-oligosaccharide mixture.

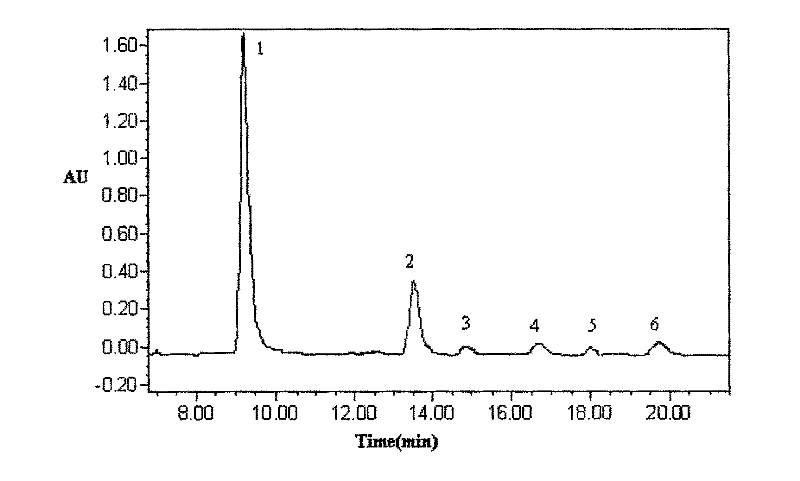

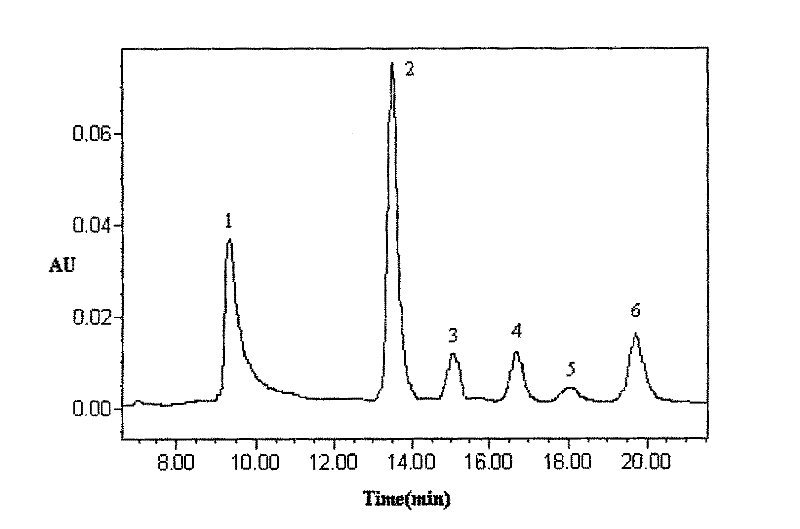

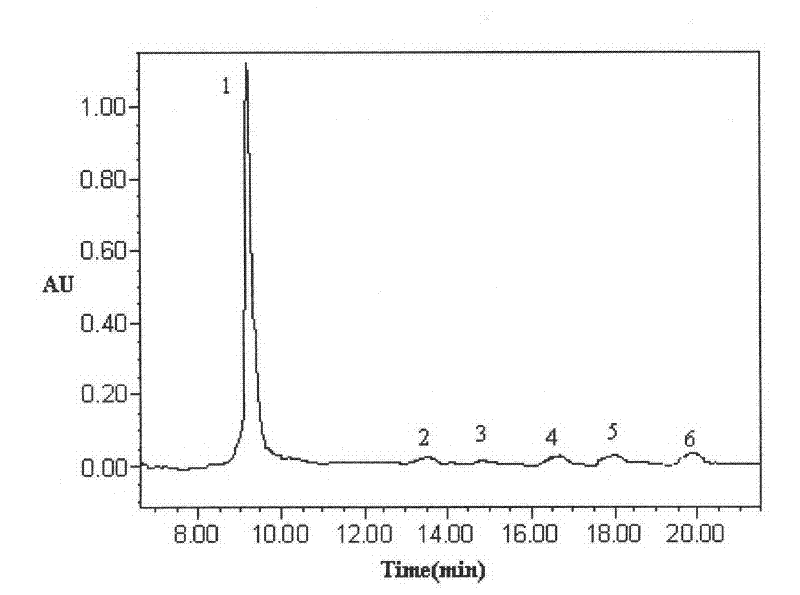

[0028] After pectin, pect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com