Golden sculpture method for wine bottle

A technology of real gold and sculpture, applied in the field of real gold sculpture for wine bottles, can solve the problems of insufficient raised height of metal patterns, easy foaming, discoloration, etc., and achieve the effect of rich color levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

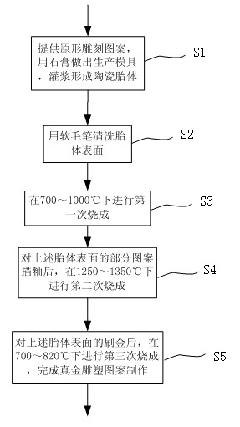

[0014] figure 1 It is a process flow chart of the real gold sculpture method for wine bottles of the present invention.

[0015] See figure 1 , the real gold sculpture method for wine bottle provided by the invention comprises the following steps in turn:

[0016] Step S1: Provide the original engraving pattern, make a production mold with gypsum, grout to form a ceramic matrix, and enter step S2;

[0017] Step S2: Clean the surface of the carcass with a soft brush. If a soft brush of T5 type is selected to avoid damaging the texture on the embryo body, proceed to step S3;

[0018] Step S3: firing the above-mentioned carcass for the first time at 700-1000° C. to remove water vapor and organic impurities in the carcass, increase the surface strength of the carcass, and proceed to step S4;

[0019] Step S4: Glaze part of the pattern on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com