Metal plate double-curved surface processing technology and equipment

A metal sheet and processing technology, which is applied in the field of hyperbolic processing of metal sheets and its processing equipment, can solve the problems that the number of hyperbolic panels processed is not large and is not applicable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

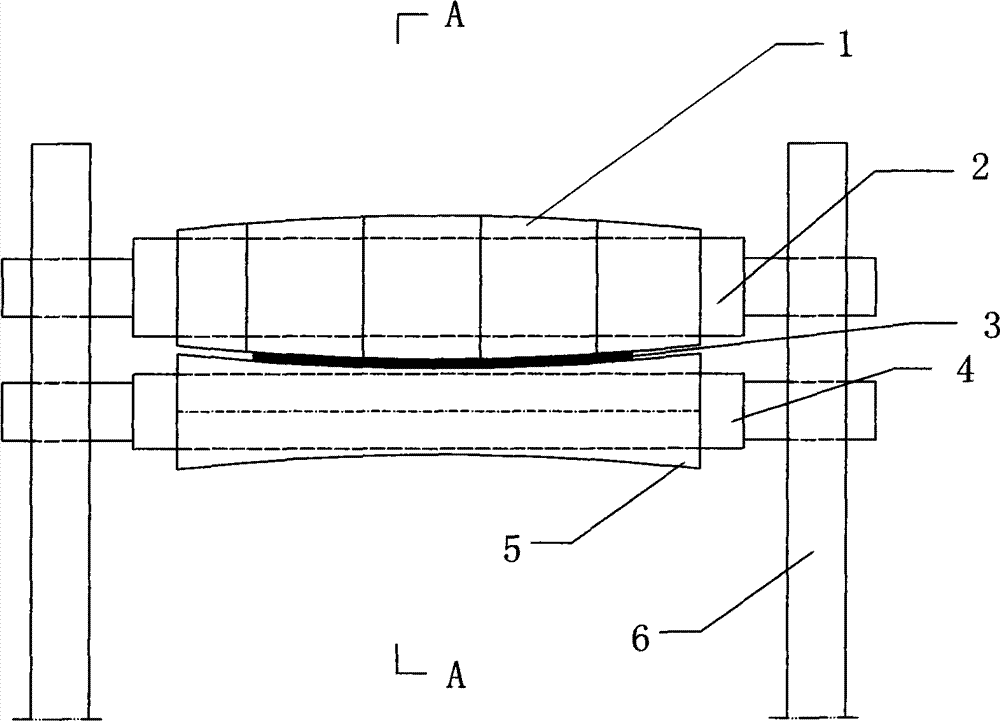

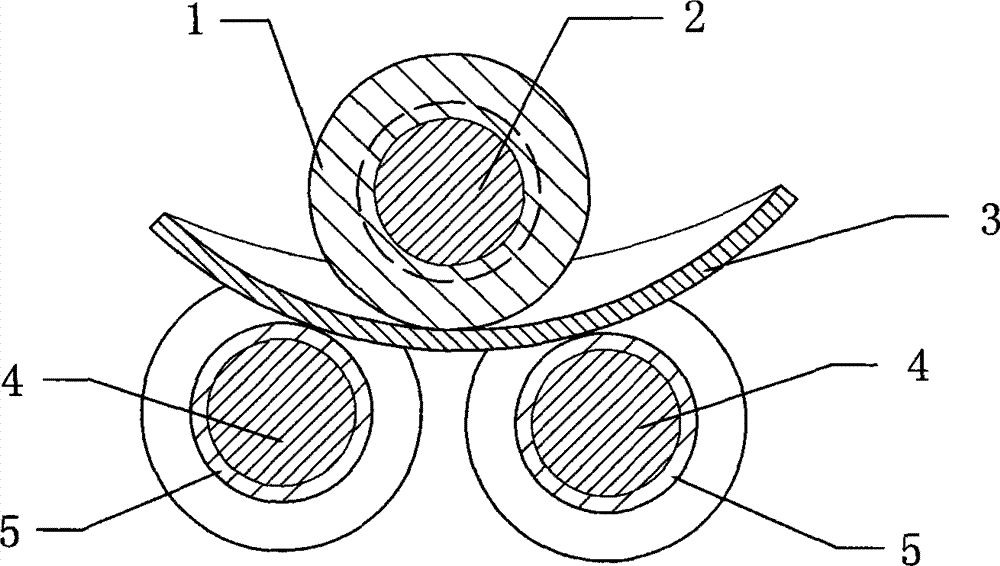

[0025] figure 1 , 2 Shown is a hyperbolic bending machine of aluminum veneer hyperbolic processing technology, the hyperbolic bending machine frame 6 is provided with three rollers 2, 4 arranged parallel to each other, including an upper shaft 2 and two The lower shaft 4, the three rollers 2 and 4 of the roll bender are provided with sleeves 1 and 5, the upper shaft 2 is provided with a convex sleeve 1, and the lower shaft 4 is provided with a concave sleeve. The shaft sleeve 5, concave and convex shaft sleeves 5 and 1 have axial curvatures that match each other, and the concave and convex curvatures ensure the curvature of the aluminum veneer 3 in the axial direction of the roll after rolling, and the metal plate to be processed passes through The roll bending machine with concave and convex sleeve shafts can form the hyperbolic panel of the required shape after rolling.

[0026] Described concave and convex axle sleeves 5,1 adopt the structural form that axially divides in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com