Process for preventing fogging and explosion of coal dried tail gas in dry bag-type dust removal process

A bag-type dust removal and explosion-proof technology, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of partial dew condensation in exhaust gas treatment, affecting continuous operation, and high dew point of dryer exhaust gas. The effect of preventing condensation and reducing running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

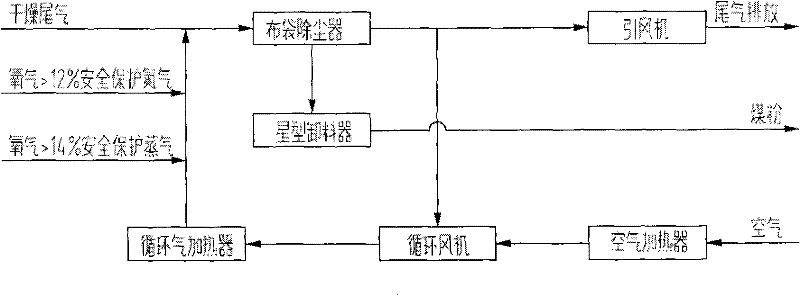

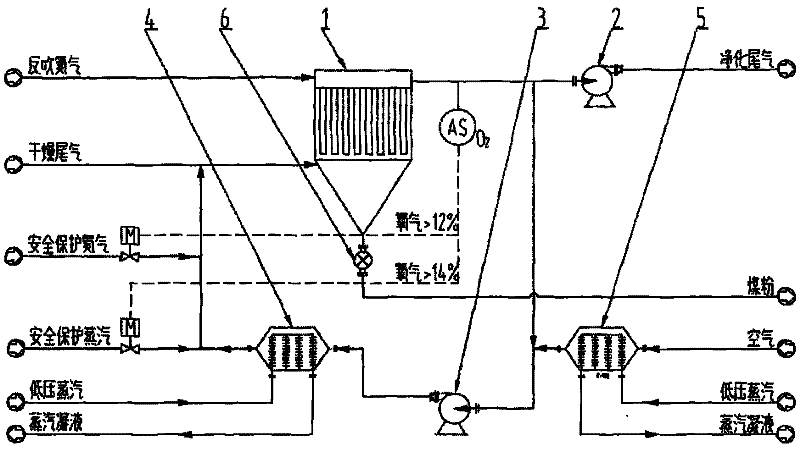

[0012] In conjunction with the accompanying drawings, the technical solution of the present invention is further described:

[0013] A kind of anti-condensation and anti-explosion process of coal drying tail gas in the dry bag type dust removal process can be carried out according to the following steps:

[0014] Such as Figure 1-Figure 2 As shown, the tail gas exhausted from the tail of the dryer with a high dew point and low oxygen content and dusty dry tail gas with an oxygen content of <12% is sucked by the induced draft fan 2 into the bag filter 1 for gas-solid separation. The separated dust is deposited at the bottom of the bag filter 1 and discharged by the star unloader 6; the purified carrier gas and water vapor are discharged to a safe place through the induced draft fan 2. Due to the high dew point of the dry tail gas, in order to prevent The tail gas condenses in the exhaust pipe and the bag filter 1, and the bag filter 1 needs to be mixed with heat, and the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com