Central heating automatic temperature regulating system for henhouses

A central heating and temperature adjustment system technology, applied in the field of animal husbandry, can solve the problems of not meeting the temperature adjustment environment requirements, uneven temperature, poor heat preservation, etc., achieve significant economic and social benefits, reduce feeding costs, and house The effect of internal temperature equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

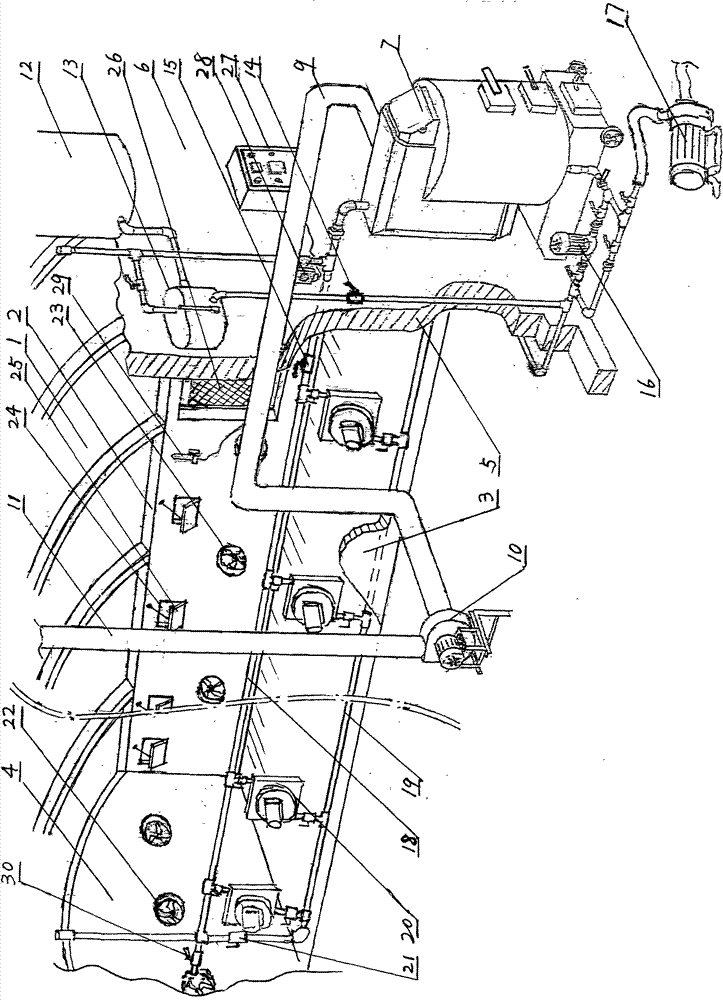

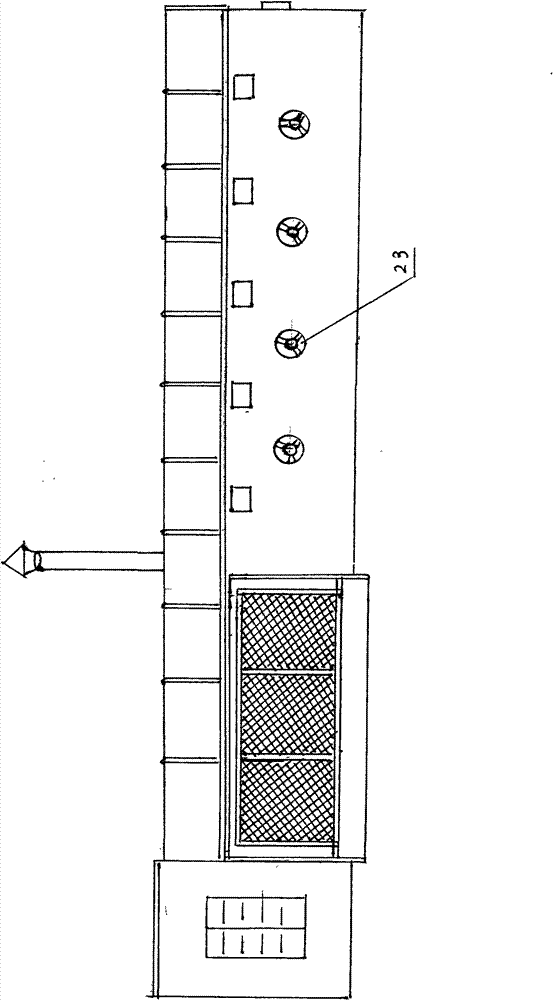

[0015] The above-mentioned drawings show a specific embodiment of the present invention, and the technical content of the present invention will be further described below in conjunction with the above-mentioned drawings.

[0016] The central heating and automatic temperature adjustment system of this chicken house includes 11 chicken houses at the front and rear to form a breeding unit. Each chicken house is 100M long and 15M wide. One-third of the length near the working room is the brooding area, and the remaining two-thirds The length is the fattening area, and central heating is provided by a boiler. The boiler 7 is located in the work room 6 at the right end (main view) of the 6th chicken house in the middle, and is connected to each chicken house by a heating pipeline 8, and is connected with each chicken house. 15 axial-flow fan radiators 20 in the lower part along the front wall 3 (ie the south wall) are connected, 9 radiators are installed in the brooding area, 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com