Electrode structure for vacuum circuit breaker

A vacuum circuit breaker and electrode structure technology, which is applied to high-voltage air circuit breakers, circuits, electric switches, etc., can solve the problems of reduced partition performance and partition failure, and achieve the effects of improved partition performance, stable longitudinal magnetic field, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

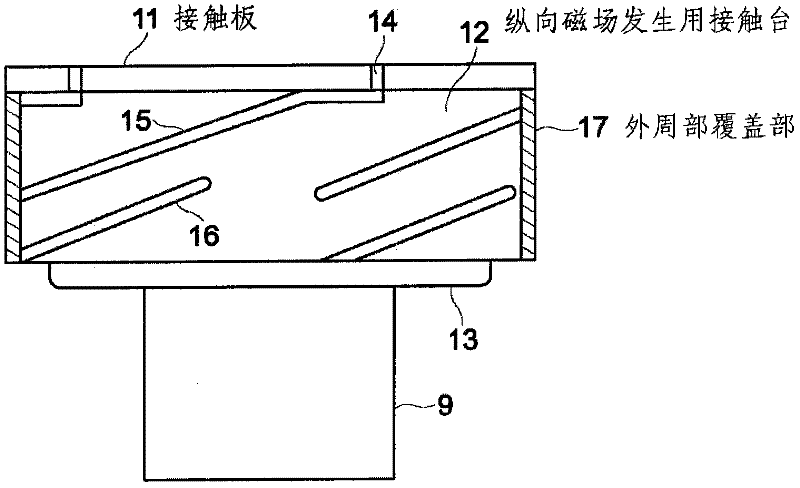

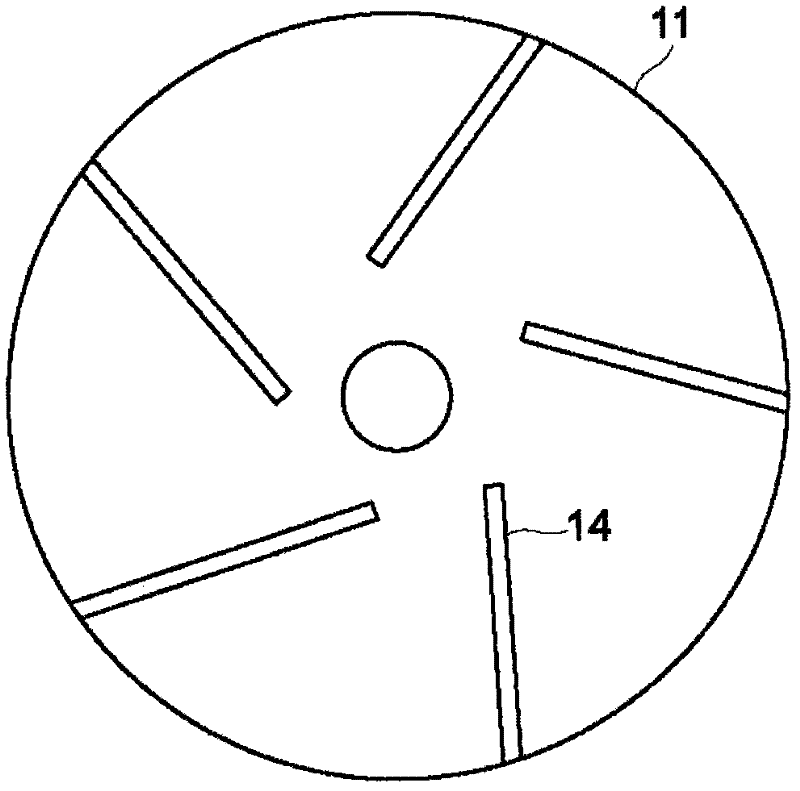

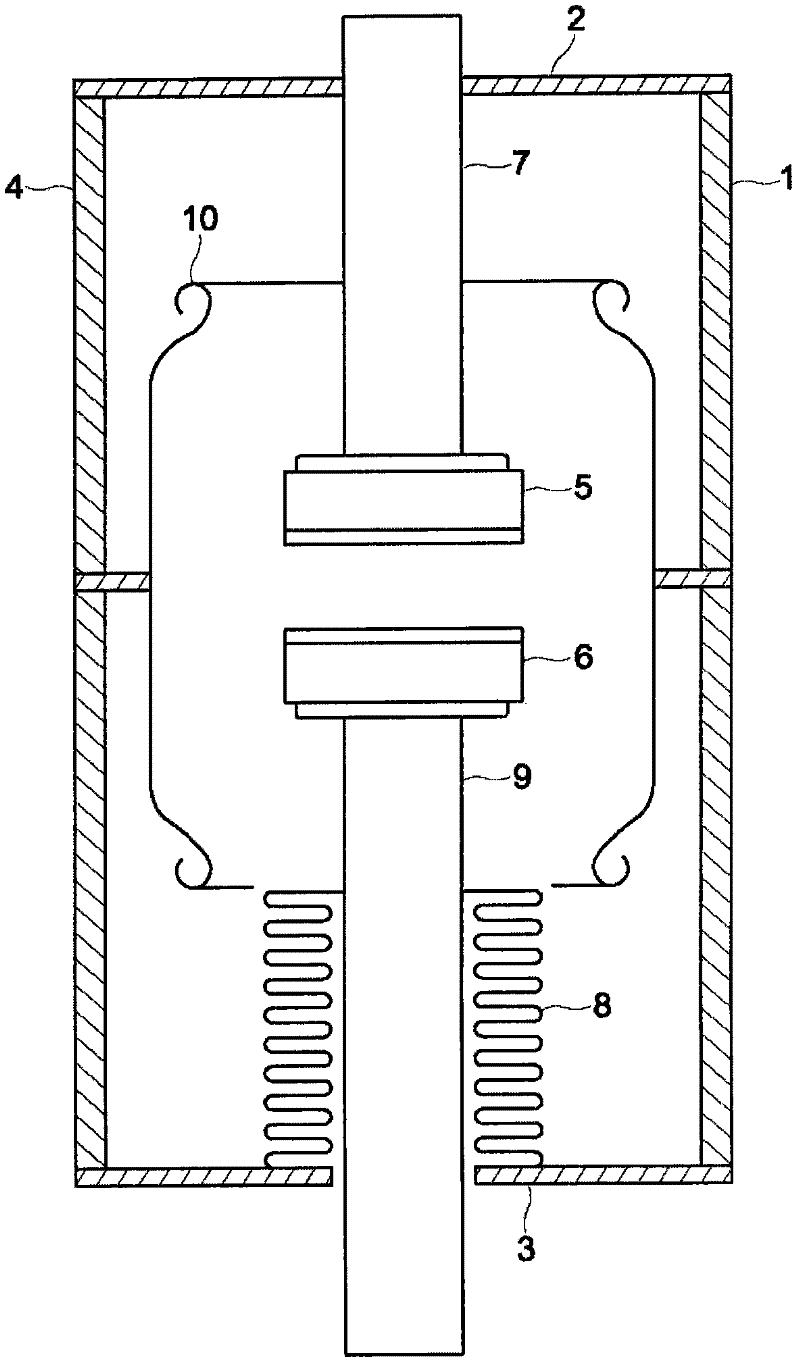

[0020] Embodiments of the electrode for a vacuum circuit breaker according to the present invention will be described below with reference to the drawings. image 3 A main part of a vacuum circuit breaker using an electrode for a vacuum circuit breaker according to an embodiment of the present invention is shown. Both ends of the insulating cylinder 1 are gas-tightly closed by end plates 2, 3 to form a vacuum container 4, and a pair of fixed-side and movable-side electrodes 5, 6 are provided to face each other inside the vacuum container 4.

[0021] The fixed side electrode 5 is fixed on the end plate 2 through the fixed side rod 7. On the other hand, the movable side electrode 6 is installed on the movable side rod 9, and the movable side rod 9 can pass through the bellows 8 to keep the vacuum container 4 While in the vacuum state, it moves along the axial direction.

[0022] The movable side lever 9 is connected to an operator not shown in the figure, and the movable side e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com