Semiconductor heating drying device

A technology of heating and drying, semi-conductor, applied in washing equipment, household dryers, textiles and paper making, etc., it can solve the problems that the drying machine cannot recover the cooling capacity of the dry air, and the temperature difference between the cold end surface and the hot end surface is large, so as to improve the production efficiency. Thermal efficiency, improving heat transfer efficiency, and expanding the effect of contact heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

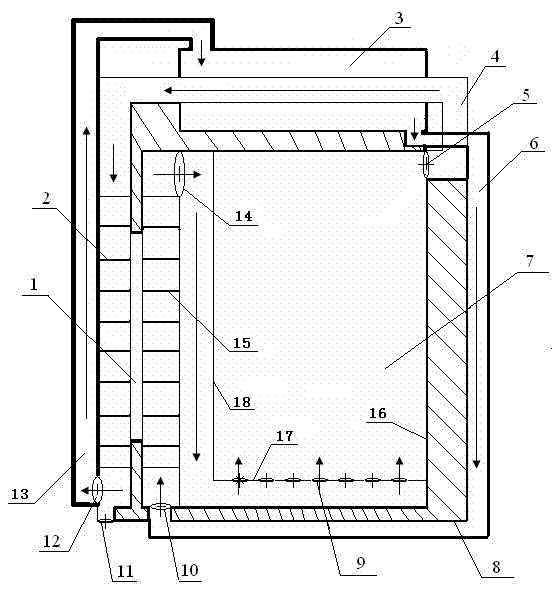

[0020] Such as figure 1 As shown, the present invention includes a box-type housing 16, a semiconductor thermopile 1, a cold-end heat exchanger 2, a hot-end heat exchanger 15 and a circulation pipeline 4, and the semiconductor thermopile 1 is embedded in the side wall of the box-type housing 16 , the cold end of the semiconductor thermopile 1 is connected to the cold end heat exchanger 2, the hot end of the semiconductor thermopile 1 is connected to the hot end heat exchanger 15, and the drying chamber 7 is separated by a vertical partition 17 in the box-type housing. The circulation pipeline 4 is fixed on the housing 16, the outer surface of the housing 16 is covered with an insulating layer 8, the inlet of the circulation pipeline is connected to the air outlet of the drying chamber 7, the outlet of the circulation pipeline 4 is connected to the upper end surface of the cold end heat exchanger 2, and the cold end A steam trap 11 is installed on the lower end of the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com