Chromium plate manufacturing process

A manufacturing process and chrome plate technology, applied in the field of chrome plate manufacturing technology, can solve problems such as chrome plate damage, and achieve the effects of high anti-static discharge damage and good pattern effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

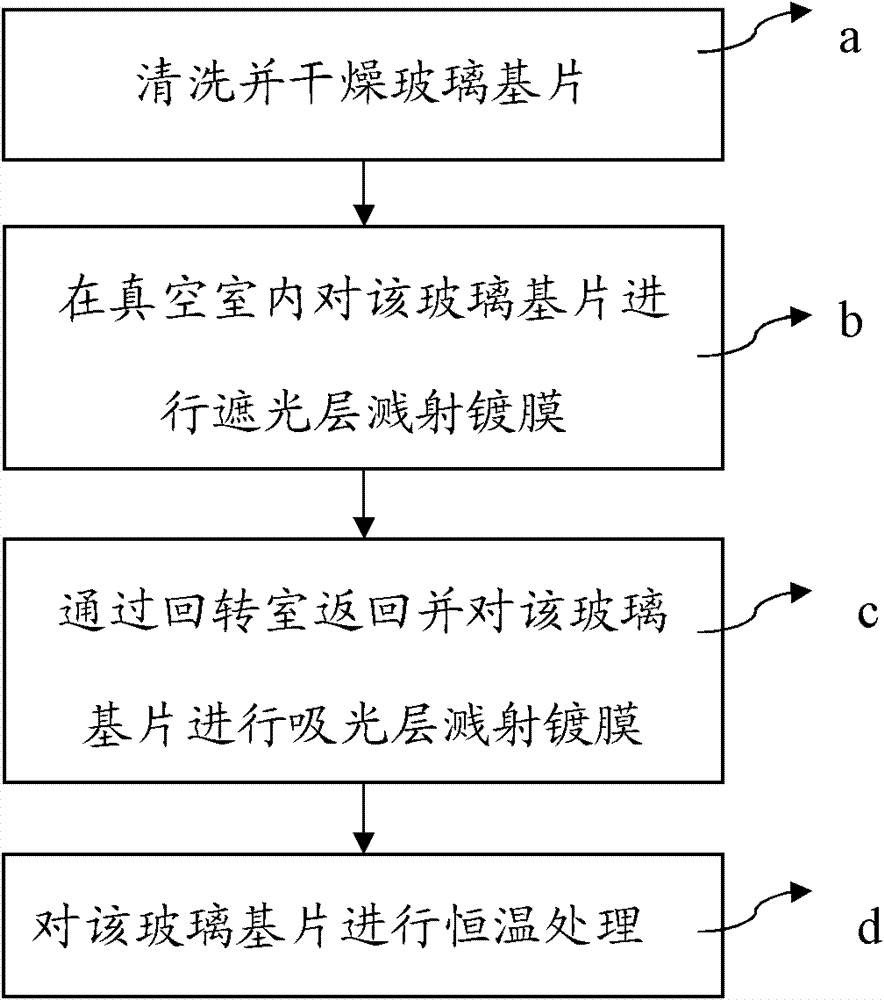

[0015] see figure 1 , is a schematic flow diagram of a preferred embodiment of the chrome plate manufacturing process of the present invention.

[0016] The chrome plate manufacturing process of the present invention comprises:

[0017] Step a, cleaning and drying the glass substrate;

[0018] In step b, the glass substrate is sputter-coated with a light-shielding layer in a vacuum chamber, wherein the transmission rate of the glass substrate is 0.25 m / min to 0.35 m / min, and the volume flow rate of argon gas is 80 ml / min to 200 m / min Standard condition ml / min, nitrogen volume flow rate is 180 standard condition ml / min to 320 standard condition ml / min, sputtering voltage is 250 volts to 650 volts, sputtering current is 1.2 amps to 3.5 amps;

[0019] Step c, return through the rotary chamber and sputter-coat the glass substrate with a light-absorbing layer, wherein the transmission rate of the glass substrate is 0.25 m / min to 0.35 m / min, and the volume flow rate of argon gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com