Production method of rare earth aluminum manganese calcium iron alloy

A ferroalloy, aluminum-manganese-calcium technology, applied in the field of rare earth aluminum-manganese-calcium-iron alloy and its production, can solve the problems of not easy to float, nodule at the nozzle, not easy to add, etc., and achieve the effects of reducing labor intensity, convenient use and high hit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

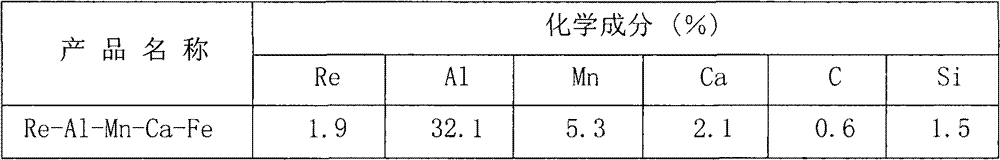

Embodiment 1

[0029] (1) The ratio of 85% aluminum ingot: 15% calcium metal is added to the induction furnace and heated for 45 minutes, the temperature is maintained at 850° C., the furnace is poured into a mold to cast into a block, and naturally cooled to form a high-alumina-calcium alloy.

[0030] (2) The ratio of 90% aluminum ingot: 10% rare earth is added to the induction furnace and heated for 38 minutes, the temperature is kept at 820° C., it is taken out of the furnace and poured into a mold to cast into a block, and cooled naturally to form a rare earth aluminum alloy.

[0031] (3) Angle iron 55%: the ratio of medium carbon ferromanganese 7% is added in the induction furnace and heated for 33 minutes, and the temperature is maintained at 1620° C., adding the prepared high aluminum calcium alloy 15%: rare earth aluminum alloy 20% smelting for 22 minutes, Turn off the power supply, add 3% aluminum ingot, cool down to 1090°C naturally, pour it into a mold and cast it into a block, and...

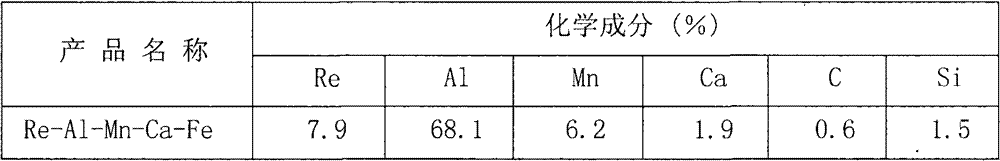

Embodiment 2

[0035] (1) The ratio of 90% aluminum ingot: 10% calcium metal is added to the induction furnace and heated for 40 minutes, the temperature is maintained at 840° C., the furnace is poured into a mold to cast into a block, and naturally cooled to form a high-alumina-calcium alloy.

[0036] (2) The ratio of aluminum ingot 86%: rare earth 14% is added to the induction furnace and heated for 40 minutes, the temperature is kept at 800°C, it is taken out of the furnace and poured into a mold to cast into a block, and naturally cooled to form a rare earth aluminum alloy.

[0037] (3) Angle iron 10%: the ratio of medium carbon ferromanganese 8% is added in the induction furnace and heated for 35 minutes, and the temperature is maintained at 1600° C., adding 20% of the prepared high-alumina-calcium alloy: 60% rare earth aluminum alloy for smelting for 20 minutes, Turn off the power supply, add 2% aluminum ingot, cool down to 1100°C naturally, pour it into a mold and cast it into a bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com