Temperable low-radiation coated glass and preparation method thereof

A low-radiation coating and glass technology, applied in the field of glass, can solve the problems of poor anti-oxidation performance of low-radiation coated glass, poor wear resistance of the film layer, incompatible performance, etc., and achieves good film layer firmness and good alkali resistance. , the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

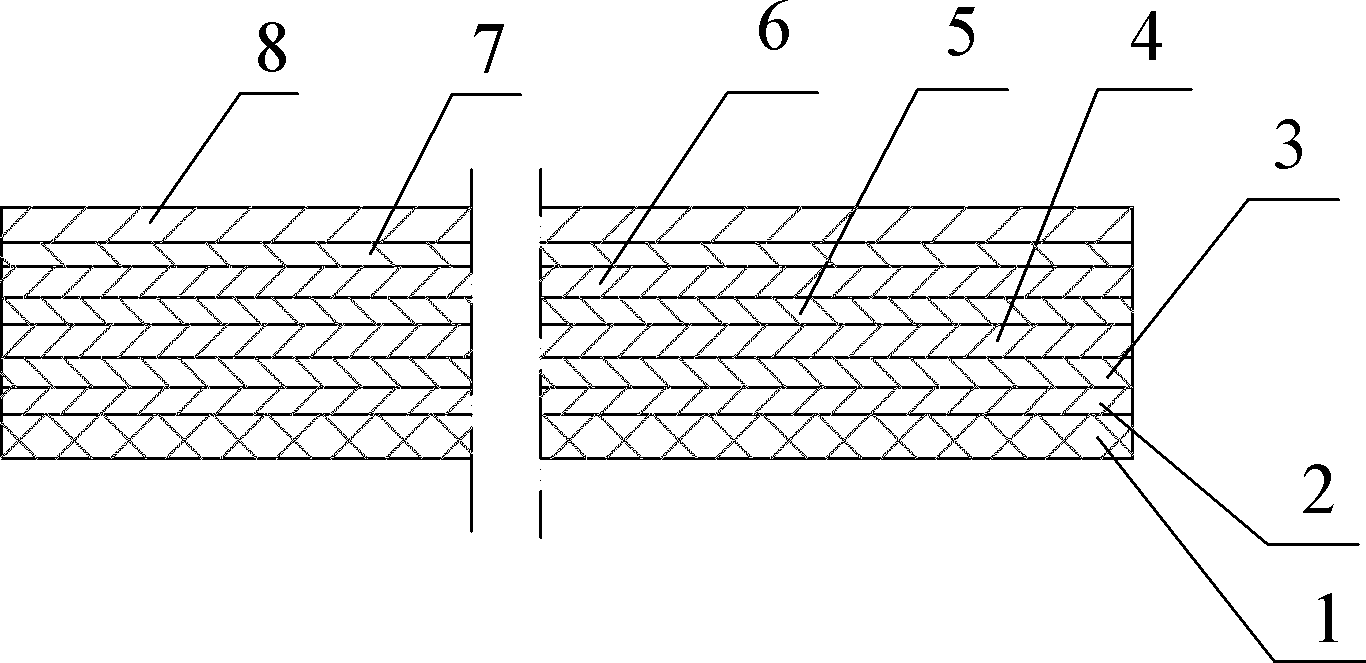

[0041] Embodiment 1, figure 1 and figure 2 Combined with a toughened low-emissivity coated glass, a dielectric layer I2, a dielectric layer II3, a metal barrier layer I4, a silver layer 5, a metal barrier layer II6, and a dielectric layer are sequentially arranged on the surface of a glass substrate 1 from bottom to top. III7 and dielectric layer IV8; dielectric layer I2 is connected to the surface of glass substrate 1, and dielectric layer I2 and dielectric layer IV8 are silicon oxide (SiO 2 ) layer, dielectric layer II3 and dielectric layer III7 are zinc oxide stannate (SnZnO 3 ) layer, the metal barrier layer I4 and the metal barrier layer II6 are nickel-chromium alloy (NiCr) layers. The glass substrate 1 has a thickness of 6 mm. The thicknesses of dielectric layer I2, dielectric layer II3, metal barrier layer I4, silver layer 5, metal barrier layer II6, dielectric layer III7 and dielectric layer IV8 are: 70nm, 68nm, 1.0nm, 9nm, 0.9nm, 58nm and 55nm.

[0042] Its prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com