Fuel injection system

A technology of injection system and fuel oil, applied in combustion engines, internal combustion piston engines, hoses, etc., can solve the problems of complicated, troublesome and rusty installation of grounding wires, and achieve the effect of improving the reliability of electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

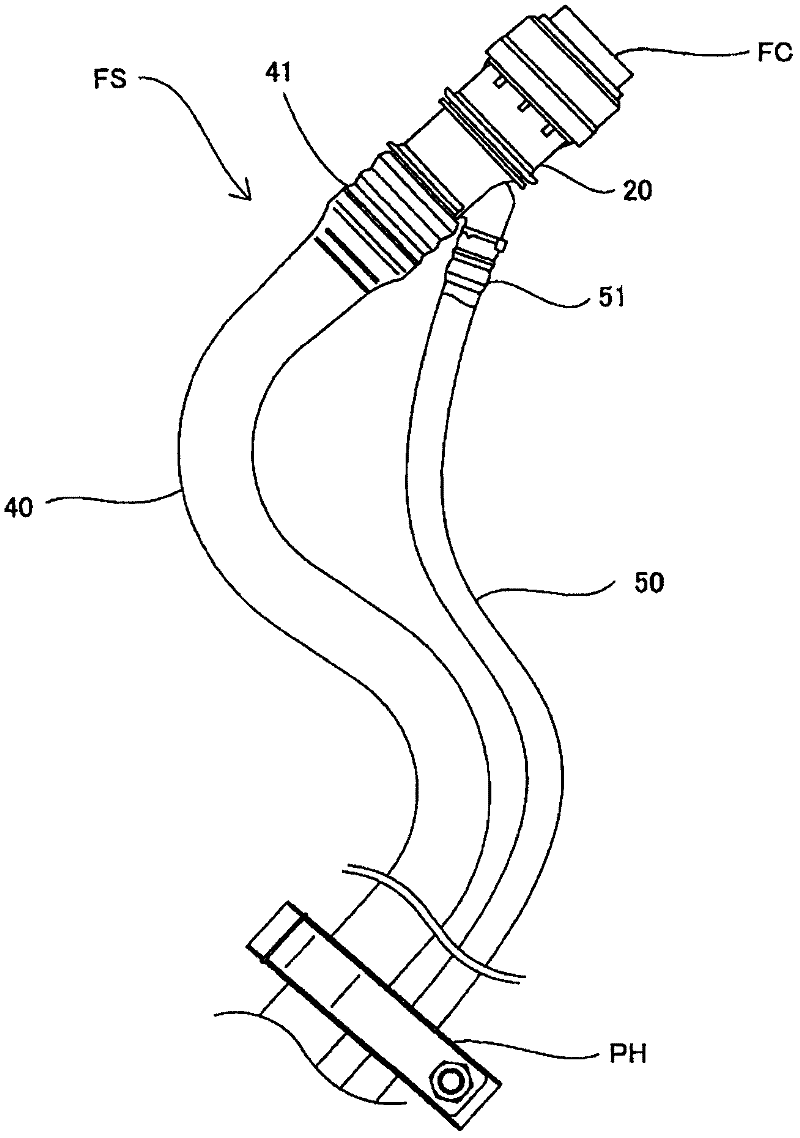

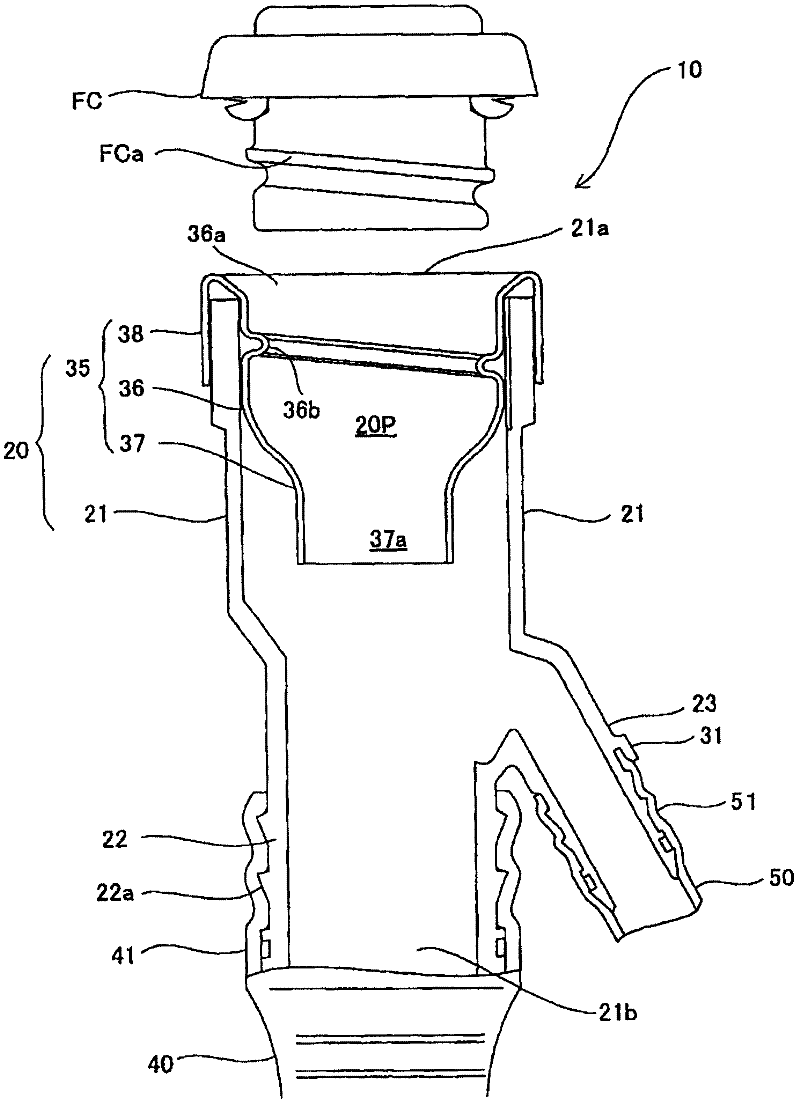

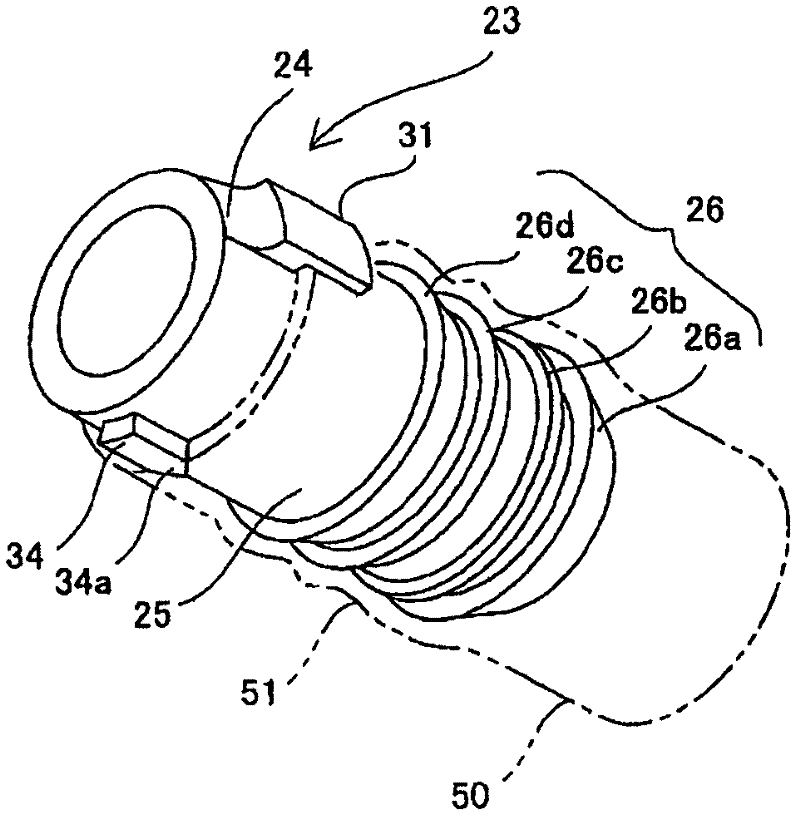

[0025] (1) Schematic structure of fuel injection system FS

[0026] figure 1 It is a schematic structural diagram showing a fuel injection system for injecting fuel into a fuel tank according to an embodiment of the present invention. The fuel injection system FS is used to inject fuel into the fuel tank of a motor vehicle, and includes: a fuel tank cap FC; a fuel filler 20; a fuel pipe 40, 50 connected to the fuel filler 20; 40, 50 are fixed to the body side parts (not shown in the figure); and, fuel tank connectors (not shown), which are used to connect the ends of the fuel pipes 40, 50 to the fuel tank. The fuel pipe 40 is a resin pipe, formed of polyethylene, which connects the filler port 20 to the fuel tank. One end of the fuel pipe 40 is configured to be suitable for connecting to the pipe joint end 41 of the filler port 20, while the other end thereof is connected to a fuel tank connector, which is welded together with the fuel tank. The fuel pipe 50 is a vent pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com