Catalyst for preparing crylic acid from propane through selective oxidation and preparation method thereof

A technology for selective oxidation and acrylic acid, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and the preparation of organic compounds. The effect of high catalytic activity and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

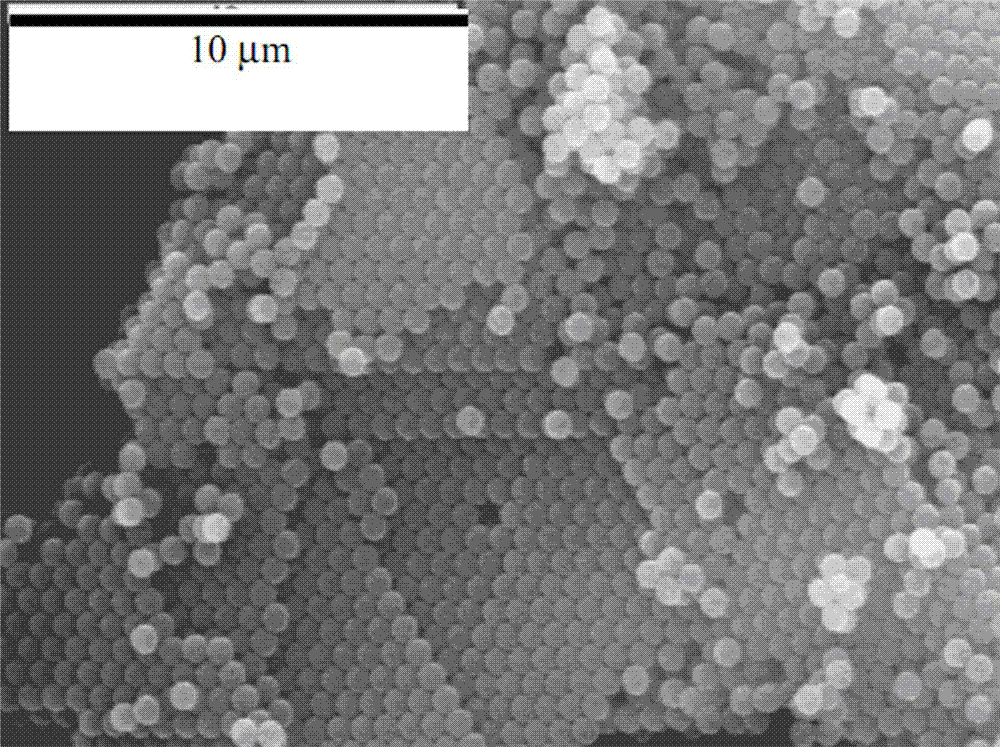

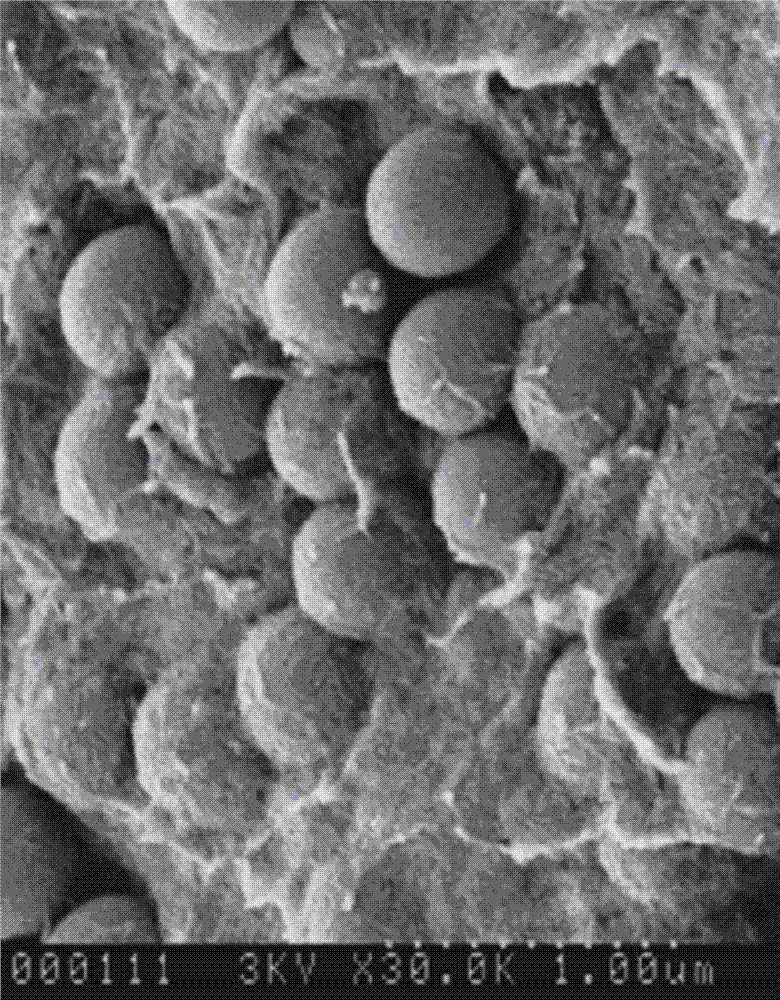

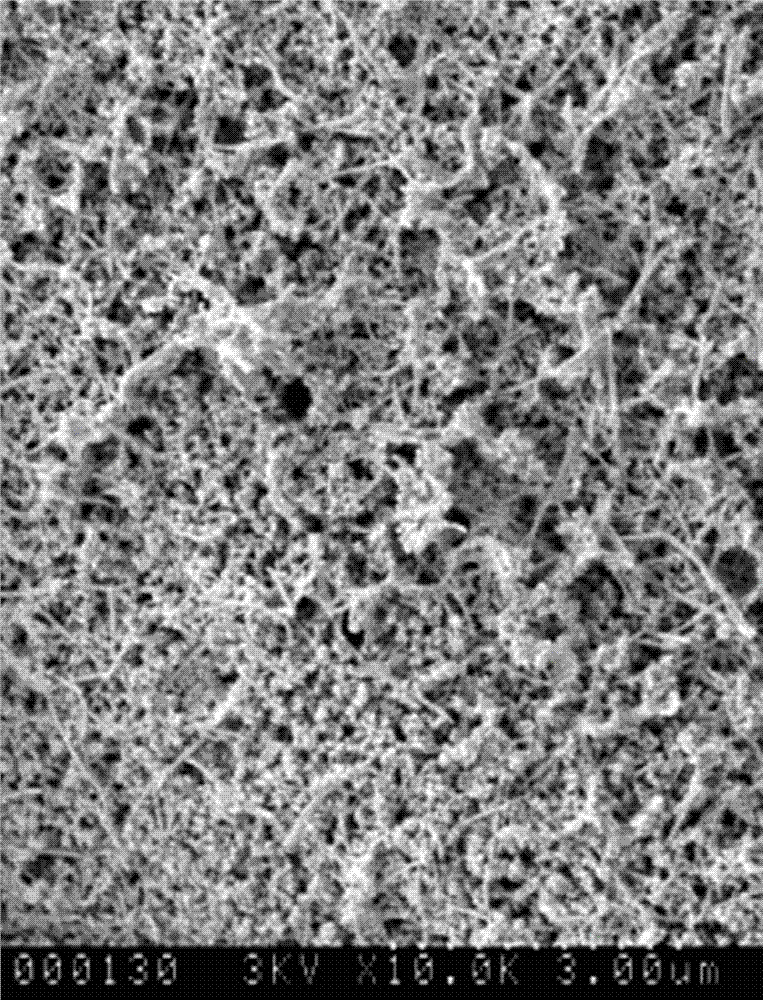

[0022] a. Place a three-necked flask on a constant temperature water bath, connect an electric stirrer, a condensing device, and a constant pressure funnel respectively, add 500 g of deionized water to the flask, heat the water bath to 65°C, and then add 0.24 g of sodium lauryl sulfate ( SDS) and sodium bicarbonate 0.35g, after stirring for 5 to 30 minutes, add 26 g of styrene monomer with a constant pressure funnel, after reacting for 5 hours, add 0.25 g of potassium persulfate, and polymerize for 20 hours to obtain monodispersity. Nice polystyrene ball emulsion template. b. Weigh 4.198g of anhydrous oxalic acid and dissolve it in a flask filled with 100ml of deionized water, stir, and heat in a water bath at 40°C; after the anhydrous oxalic acid is completely dissolved, add 1.715g of niobium hydroxide, continue stirring, and cool down to 25°C , to obtain a colorless solution ①; weigh 14.2g ammonium molybdate, 2.283 g ammonium metavanadate and 4.25 g telluric acid dissolved i...

Embodiment 2

[0024] The 0.24 g of sodium dodecyl sulfate (SDS) in Example 1 was changed to 0.15 g of sodium benzenesulfonate, and the rest was the same as in Example 1. The performance evaluation results of the catalyst are shown in Table 1.

Embodiment 3

[0026] The 0.24g sodium dodecyl sulfate (SDS) in Example 1 was changed to 0.18g sodium dodecyl sulfate (SDS), and the rest was the same as the preparation method of Example 1. The performance evaluation results of the catalyst are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com