Low-conductivity super-long-acting organic base type anti-freezing cooling liquid

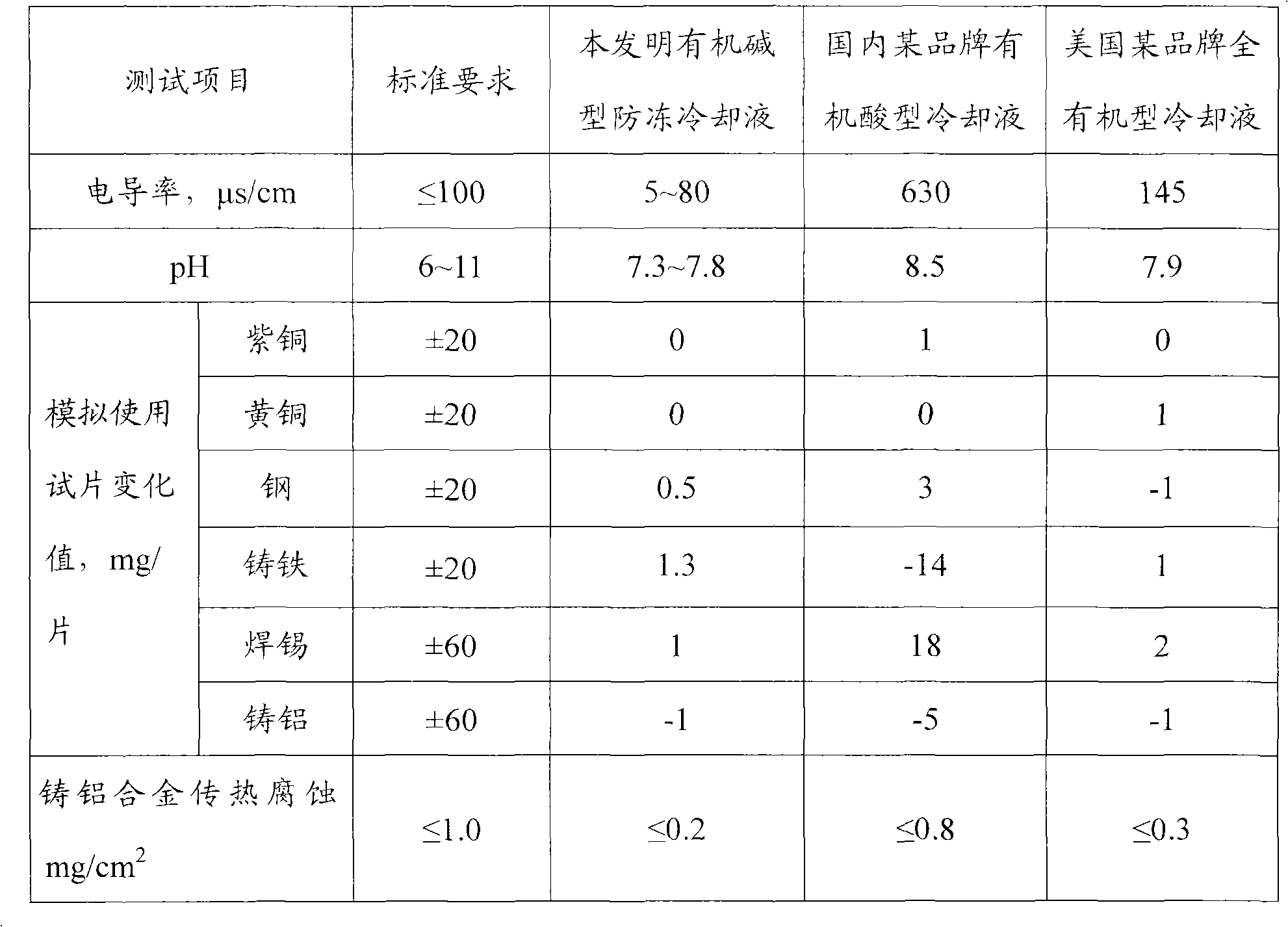

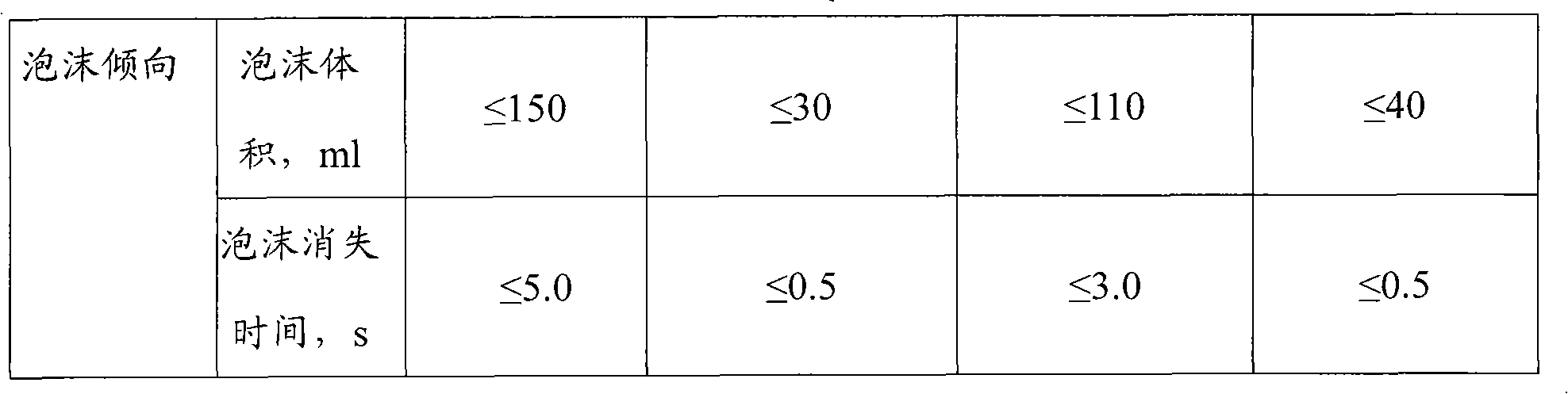

An antifreeze coolant, low conductivity technology, applied in low conductivity, organic base type antifreeze coolant, ultra-long-acting field, can solve the problems of poor solubility of organic carboxylic acid, complicated production process, easy precipitation, etc., to achieve stability The effect of storage, low desorption rate and high boiling point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 10kg of ethylene glycol, 5kg of propylene glycol, and 83.5kg of deionized water and stir for 5 minutes at room temperature, then add 0.3kg of coucine, 0.95kg of aziridine, and 0.25kg of tolylbenzotriazole in sequence, and mix at 40°C Stir for 30 min until a homogeneous stable solution is formed.

Embodiment 2

[0024] Get 20kg of ethylene glycol, 15kg of propylene glycol, 62kg of deionized water and stir for 5min at room temperature, then add 0.55kg of vincristine, 1.1kg of piperazine hexahydrate and 1.1kg of aziridine, and 0.25kg of mercaptobenzothiazole successively at 40 Stir at ℃ for 30 min until a uniform and stable solution is formed.

Embodiment 3

[0026] Take 55kg of propylene glycol, 44kg of deionized water and stir for 5min at room temperature, then add, arecoline 0.2kg, p-oxazepine 0.5kg, methyl benzotriazole and 3-amino-4,5-dimethyliso 0.15 kg each of oxazole, and stirred at 40°C for 30 min until a uniform and stable solution was formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com