Method for preparing controlled degradable polypropylene foamed particles

A technology of foamed particles and polypropylene, which is applied in the field of preparation of controllable degradable polypropylene foamed particles, to achieve the effects of increasing plasticization, reducing use costs, and reducing foaming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

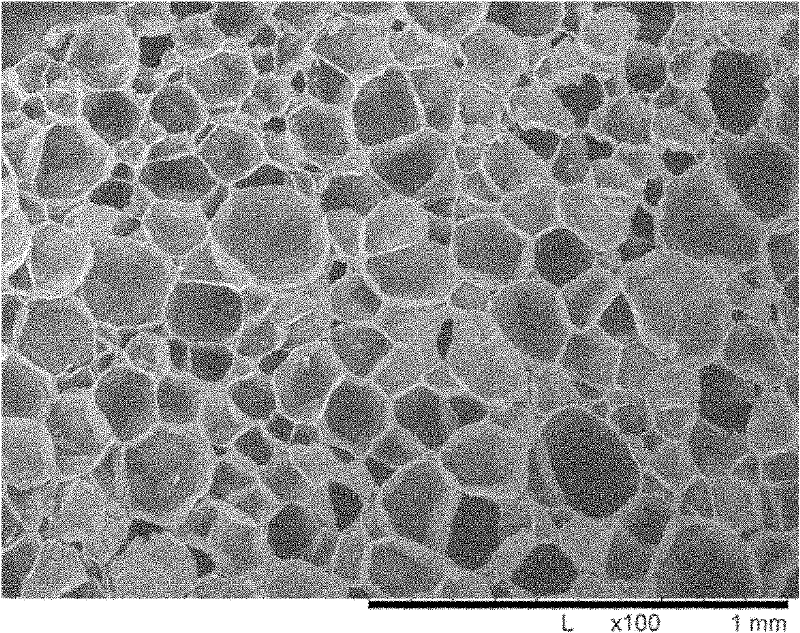

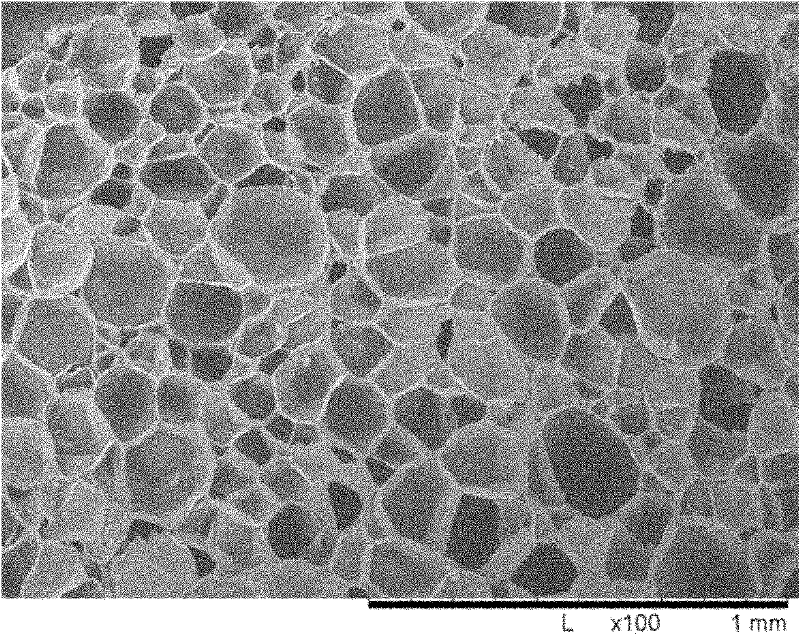

Image

Examples

Embodiment 1

[0028] Add the blend of polypropylene, polylactic acid and mica to the twin-screw extruder, according to the mass percentage, polylactic acid accounts for 20% of the blend, mica accounts for 1%, and the polymer melt is extruded by twin-screw Transfer and transport to the die mouth of the extruder, granulate after water cooling. The die chosen had 12 holes, each hole had a diameter of 0.6 mm, and the resulting polymer pellets had a diameter of 0.9 mm to 1.2 mm.

[0029] Put 1 kg of polymer pellets, 5 liters of water, and 6.0vol% pentane into the autoclave, and raise the temperature of the autoclave to 85°C, 90°C, and 97.5°C under stirring conditions, and saturate at 1.5°C at constant temperature and pressure. hours to allow the alkane blowing agent to penetrate into the sample. The autoclave is quickly released within 30 seconds, and the materials in the autoclave and liquid materials are quickly ejected out of the autoclave vent valve, and the polymer pellets are rapidly expa...

Embodiment 2

[0040] Add the blend of polypropylene, polybutylene succinate and nano-montmorillonite to the twin-screw extruder, and polybutylene succinate accounts for 30% of the blend in terms of mass percentage , nano-montmorillonite accounted for 1%, the polymer melt is transported to the die of the extruder through twin-screw extrusion, and granulated after water cooling. The die chosen had 12 holes, each hole had a diameter of 0.6 mm, and the resulting polymer pellets had a diameter of 0.9 mm to 1.2 mm.

[0041] Put 1 kg of polypropylene blend, 5 liters of water, and 6.0vol% pentane into the autoclave, and raise the temperature of the autoclave to 75°C, 85°C, and 92°C under stirring conditions, and saturate at constant temperature and pressure 1.0 hour to allow the alkane blowing agent to penetrate into the sample. The autoclave is quickly released within 30 seconds, and the materials in the autoclave and liquid materials are quickly ejected out of the autoclave vent valve, and the p...

Embodiment 3

[0051] The blend of polypropylene and polyhydroxybutyrate is added to the twin-screw extruder, in terms of mass percentage, polyhydroxybutyrate accounts for 5% of the blend, and the polymer melt is transferred through twin-screw extrusion Transport to the die of extruder, granulate after water cooling. The die chosen had 12 holes, each hole had a diameter of 0.6 mm, and the resulting polymer pellets had a diameter of 0.9 mm to 1.2 mm.

[0052] Put 1 kg of polymer pellets, 5 liters of water, and 4.0vol% HFC-245fa into the autoclave, raise the temperature of the autoclave to 88°C, 92°C, and 98°C under stirring conditions, and inject co-foaming Agent CO 2 Make the pressure of the kettle to 1 MPa, and saturate at constant temperature and pressure for 6 hours, so that the HFC foaming agent can penetrate into the sample. The autoclave is quickly released within 30 seconds, and the materials in the autoclave and liquid materials are quickly ejected out of the autoclave vent valve, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cell density | aaaaa | aaaaa |

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com