Phosphorous removing agent for wastewater produced during producing organophosphorus pesticides and preparation method thereof

A technology of organophosphorus pesticide and phosphorus removal agent, which is applied in the field of environmental remediation and achieves the effects of simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

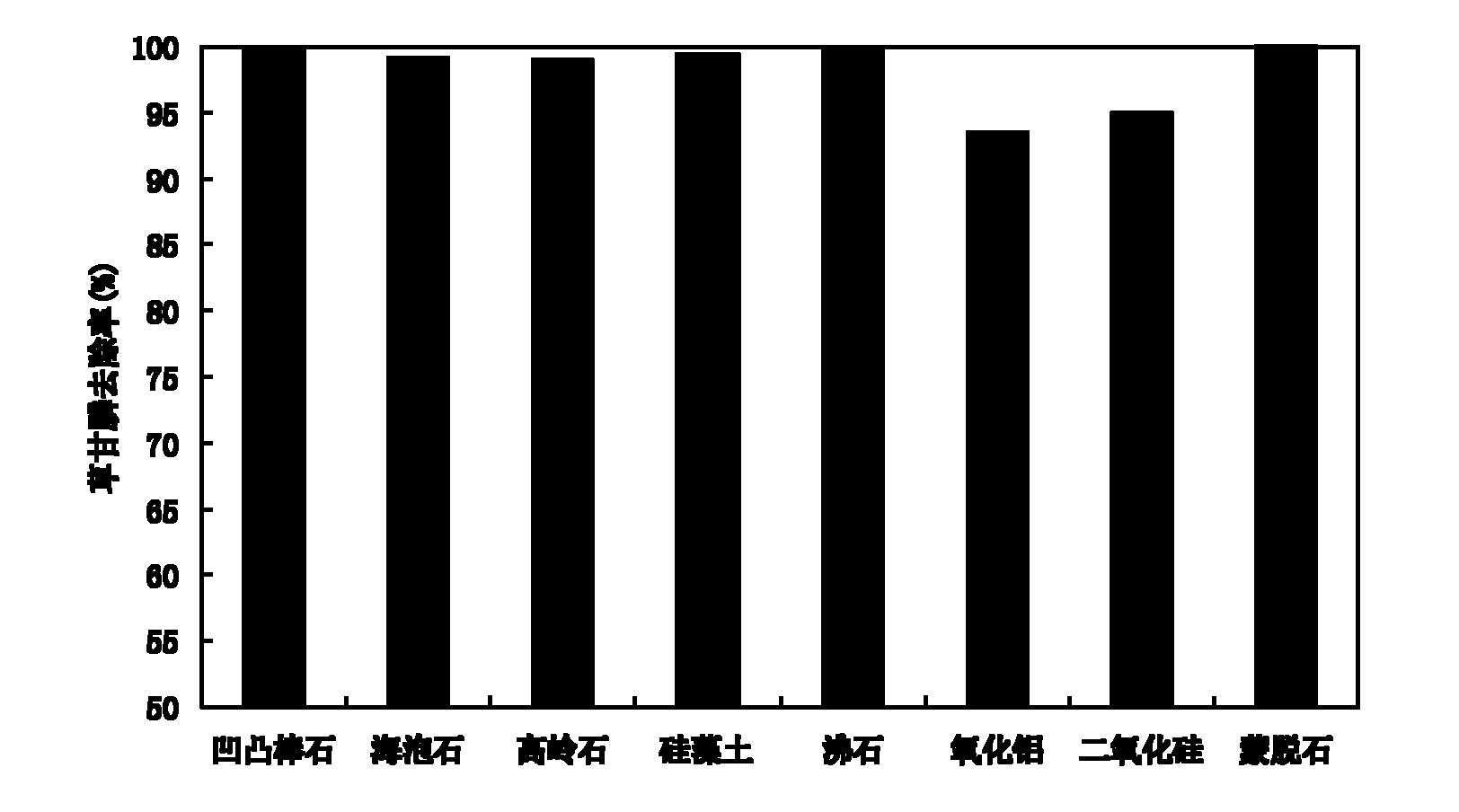

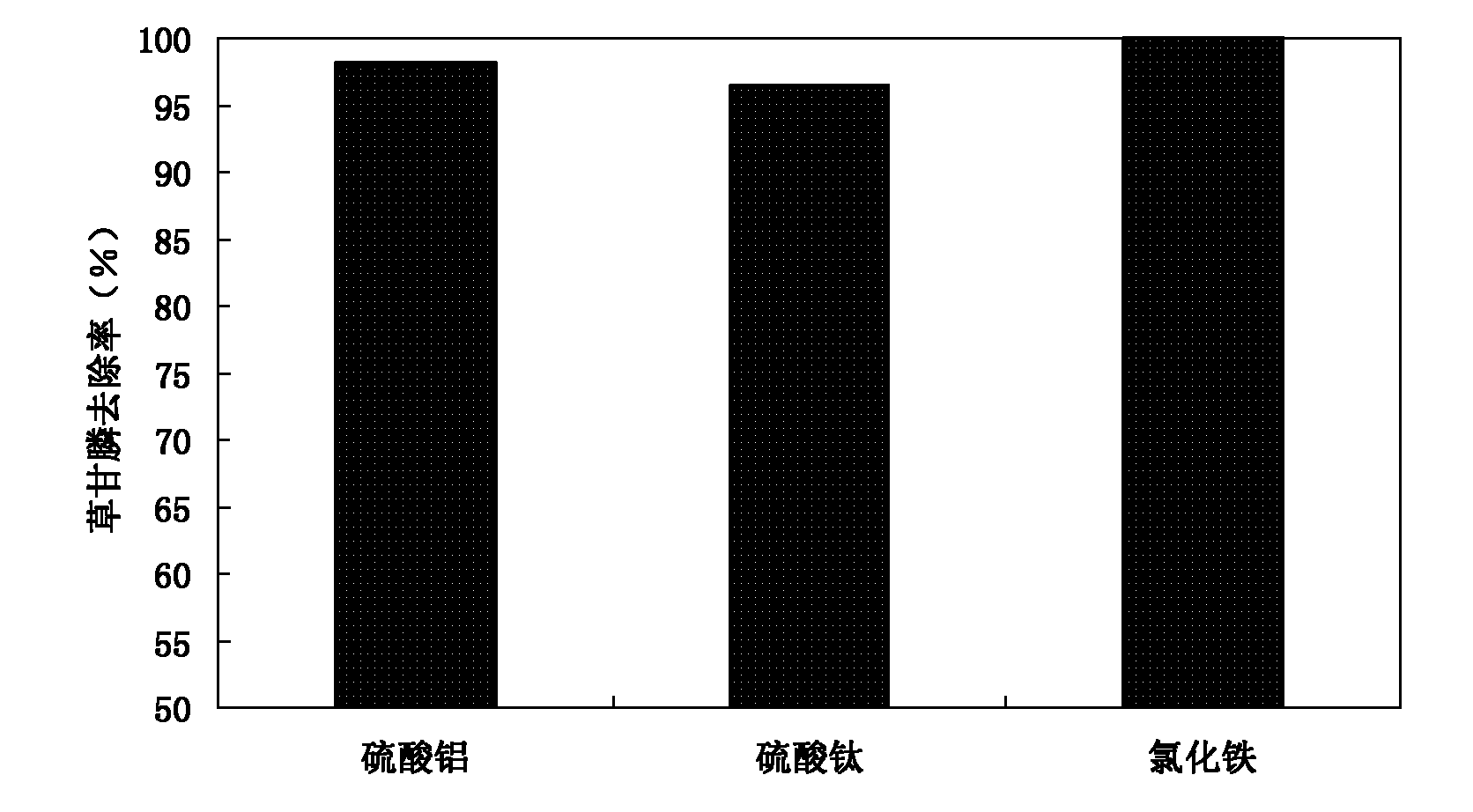

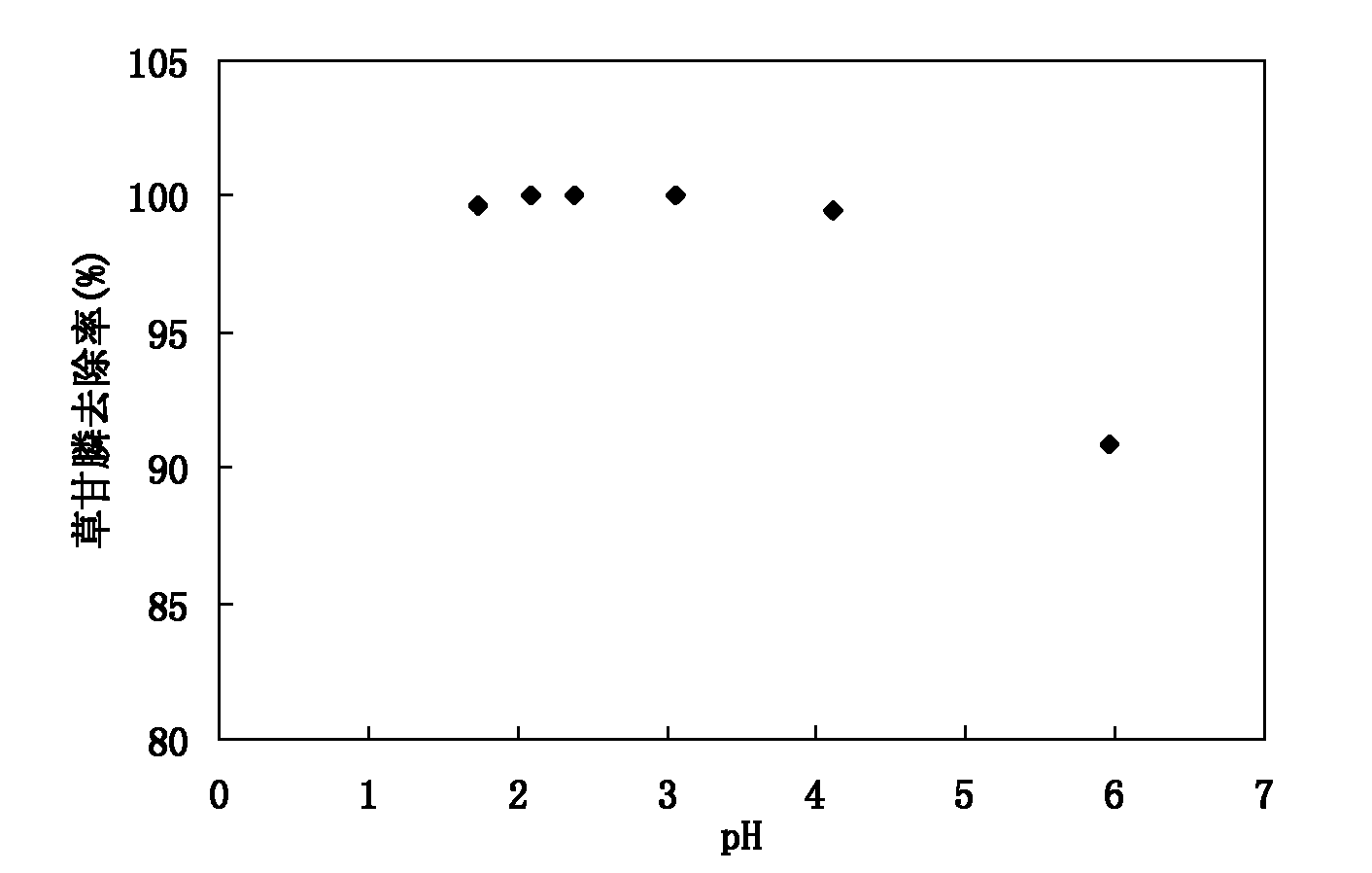

Method used

Image

Examples

Embodiment 1

[0017] Weigh 70%, 28% and 2% montmorillonite, attapulgite and ferric chloride in sequence according to the mass percentage, grind them, and burn them at ≤500°C for 2 hours to obtain a phosphorus removal agent for organophosphorus pesticide wastewater. According to the dosage of 10g / L, add phosphorus removal agent to the glyphosate wastewater with a concentration of 103mg / L (calculated as P), and react at 60°C for 30min. Filter and measure the concentration of TP in the solution. The results show that the phosphorus removal agent can achieve 99% removal rate of total phosphorus in glyphosate wastewater.

Embodiment 2

[0019] Weigh 98%, 1% and 1% montmorillonite, lanthanum oxide, and titanium sulfate in sequence according to mass percentage, grind them, and burn them at ≤500°C for 2 hours to obtain a phosphorus removal agent for organophosphorus pesticide wastewater. According to the dosage of 12g / L, add phosphorus removal agent to the glufosinate-ammonium wastewater with a concentration of 100mg / L (calculated as P), and react at 60°C for 30min. Filter and measure the concentration of TP in the solution. The results showed that the total phosphorus removal rate of glufosinate-ammonium wastewater could reach 99%.

Embodiment 3

[0021] Weigh 60%, 38%, 1%, and 1% of attapulgite, sepiolite, aluminum sulfate, and lanthanum oxide in sequence according to mass percentage, grind them, and burn them at ≤500°C for 2 hours to obtain organophosphorus pesticide wastewater Phosphorus removal agent. According to the dosage of 10g / L, add the dephosphorization agent to the diglyphosate wastewater with a concentration of 58mg / L (calculated as P), and react at 60°C for 30min. Filter and measure the concentration of TP in the solution. The results showed that the total phosphorus removal rate of glufosinate-ammonium wastewater could reach 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com