Parameter adjustable type polishing clamp device for heavy-calibre plane optical element

A technology for optical components and polishing fixtures, applied in optical surface grinders, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as uncertainty, low processing efficiency, and uncontrollable pressure in the contact area between components and polishing pads. Achieve the effect of fine control range, large control range and high material removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

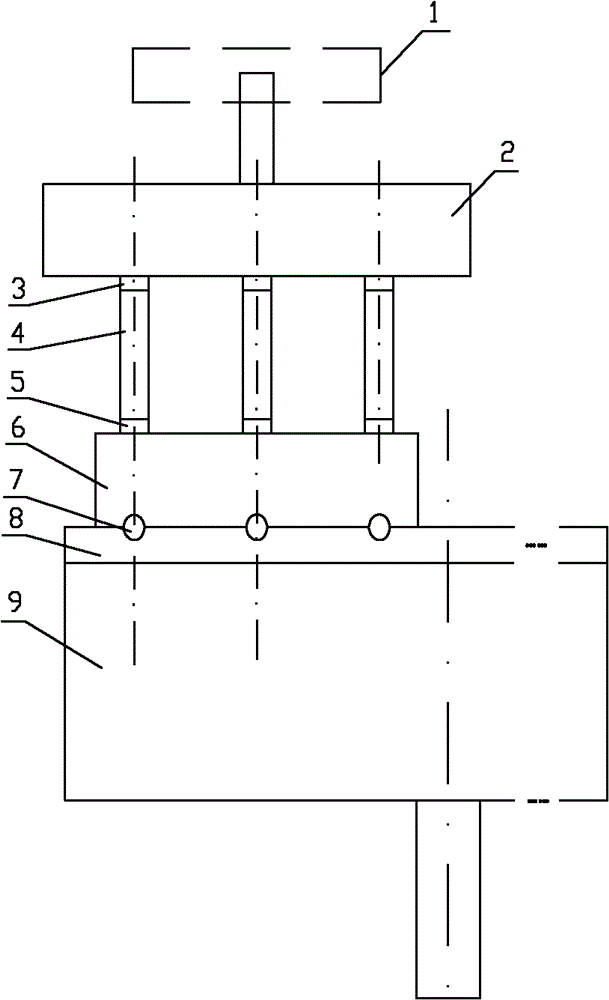

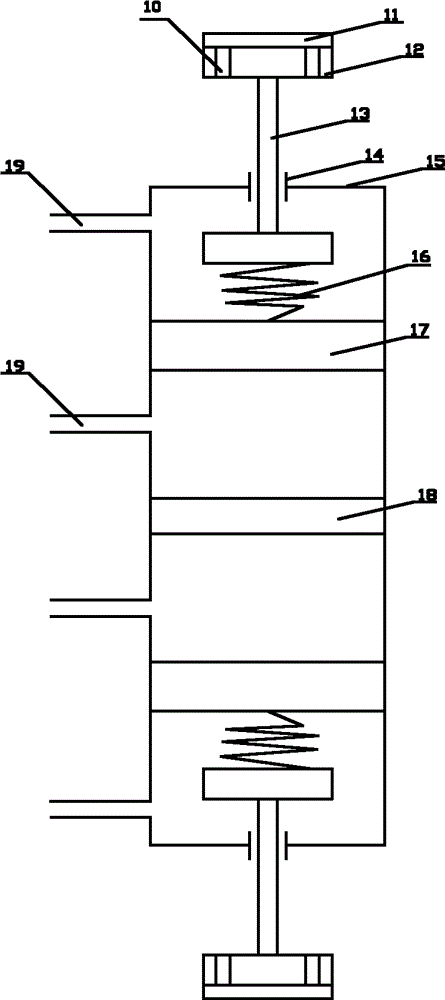

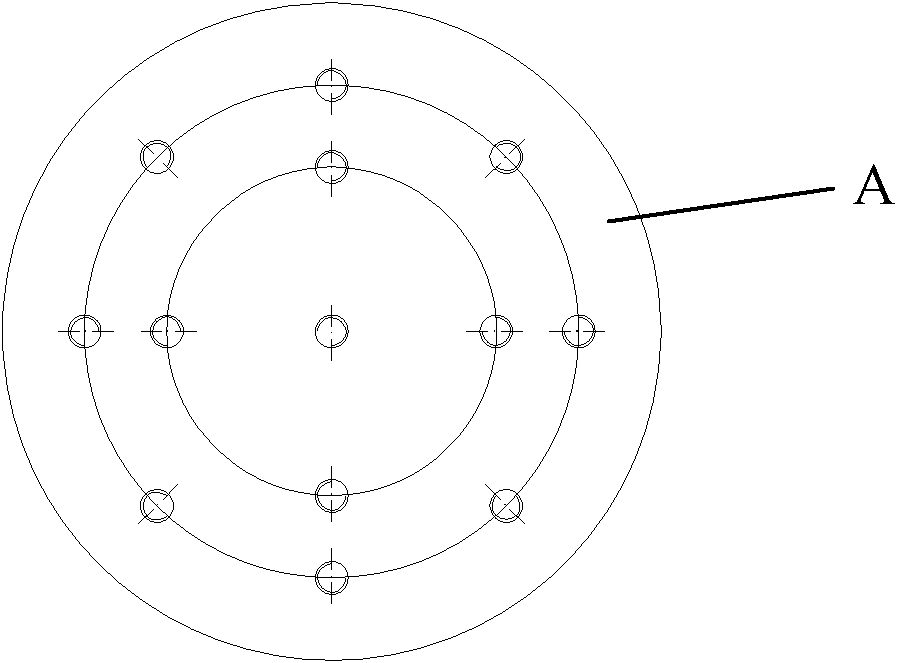

[0016] see figure 1 , figure 1 The middle polishing pad 8 and the polishing disc 9 are symmetrical, only the left part is drawn, not all of them are drawn, and a part is omitted. The mass block 1 can be inserted through the central axis of the upper surface of the fixture plate 2 according to processing requirements. The sensor 7 is embedded in the polishing pad 8, and the pressure signal is input to the data acquisition card after passing through the servo amplifier, and the data acquisition card is installed on the industrial computer. According to the collected pressure data, it is compared with the pressure applied to each part of the component surface by the upper hydraulic piston device and the lower hydraulic piston device at the initial design stage, and the hydraulic pressure is adjusted through the hydraulic oil delivery and oil return device to change the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com