Controllable and ablated non-conductive engineering ceramic grinding method based on discharge induction

An engineering ceramics and grinding technology, which is applied to the processing of non-conductive and difficult-to-machine materials, and the field of grinding of non-conductive engineering ceramics, can solve the problems of low processing efficiency of insulating materials, and achieve low processing efficiency and low grinding wheel loss. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

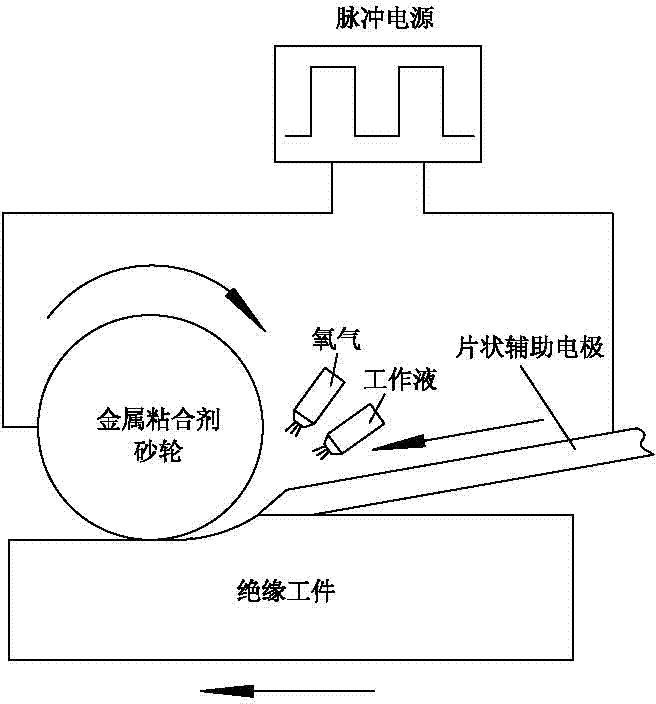

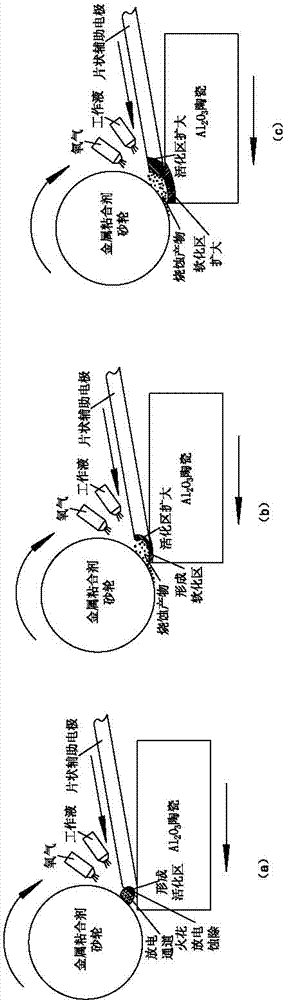

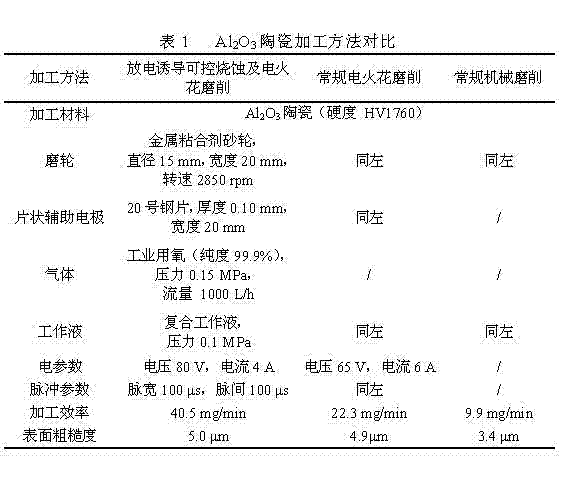

[0034] like figure 1 , 2 shown.

[0035] A grinding method based on discharge-induced controllable ablation of non-conductive engineering ceramics, comprising the following steps:

[0036] First, use a conductive metal bonded grinding wheel as the grinding wheel, and do high-speed rotating motion, between the grinding wheel and non-conductive engineering ceramics (can be Al 2 o 3 Ceramic, ZrO 2 Ceramic, Si 3 N 4 Ceramics or SiC ceramics) rely on the feeding mechanism to continuously feed the conductive auxiliary electrodes. The conductive auxiliary electrodes should be sheet-shaped conductive auxiliary electrodes. One or a combination of more than one of the iron-based materials or non-ferrous metal alloys (such as titanium alloys) that undergo violent exothermic reactions. In order to make the controlled ablation as close as possible to the proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com