Self-cooling technology for machined twist drill and machining method for machined twist drill

A processing method, twist drill technology, applied in twist drills, metal processing equipment, parts of boring machines/drilling machines, etc., can solve problems such as inability to achieve cooling effect, twist drills are not durable, and the hardness of the cutter head is reduced, so as to save resources , Improve efficiency and reduce cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

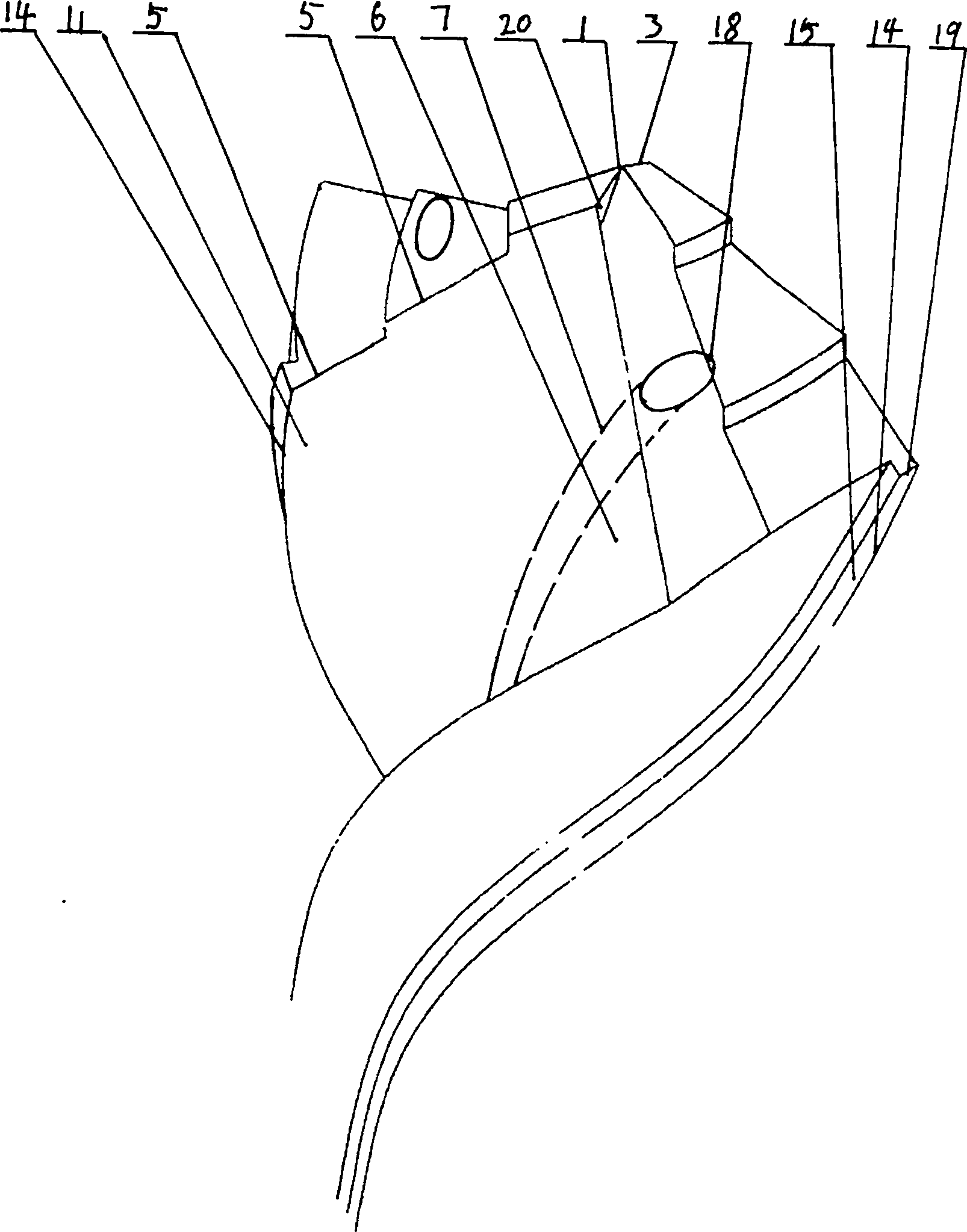

[0036] Such as figure 1 , Figure 7-Figure 10 , Figure 11-Figure 14 As shown, the self-cooling technology and processing method of the machine-added twist drill of the first embodiment of the present invention mainly relate to the machine-added twist drill for mechanical processing, and the self-cooling technology of the machine-added twist drill of the first embodiment of the present invention Cooling technology and processing method thereof, mainly relate to machine-added twist drills for mechanical processing, wherein, Figure 7 The drill point in the axial center is not chamfered, so the chisel edge is larger and the cutting resistance is also larger. Figure 8 Although the drill point in the axial center is chamfered, there is still a reduced chisel edge, and the cutting resistance is relatively Figure 7 reduced a lot, Figure 9-Figure 10 After chamfering, the drill point in the axial center has become a sharp edge without a chisel edge, and the cutting resistance i...

Embodiment approach 2

[0040] Such as figure 2 , Figure 6 , Figure 7-Figure 10 ,picture- Figure 14 As shown in Embodiment 2, the self-cooling technology and processing method of the machine-added twist drill of the second embodiment of the present invention, on the basis of the first embodiment, the present invention is a step-shaped protrusion on the rear cutting surface 4 At least one level of stepped composite rear cutting surface 4 is provided, and the stepped composite rear cutting surface 4 intersects with the helical cutting surface 11 to form a stepped composite cutting edge 5 .

[0041] The step-like setting on the rear cutting surface 4 not only improves the cutting stability of the twist drill but also improves the efficiency, reduces the cost and saves resources.

[0042] According to the above structure, it has been proved that the effect of cooling the tool from the cutting place by the coolant is far greater than that achieved by flowing downward from the top. On the one hand,...

Embodiment approach 3

[0044] Such as image 3 , Figure 7-Figure 10 ,picture- Figure 14 As shown, the self-cooling technology and processing method of the machine-added twist drill of the third embodiment of the present invention, on the basis of the first-second embodiment, the present invention is mainly provided with at least one notch on the cutting edge 5 The edge 50 extends toward the rear cutting surface 4 to form a groove 51 .

[0045] By arranging the notch edge 50 on the cutting edge 5, the cutting resistance of the cutting edge 5 is broken down, the cutting efficiency is greatly improved, the cost is reduced, and resources are saved.

[0046] According to the above structure, it has been proved that the effect of cooling the tool from the cutting place by the coolant is far greater than that achieved by flowing downward from the top. On the one hand, the waste chips cut by the tool also prevent the coolant from reaching the cutting place effectively, but the way of sending the coolan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com