Combined honeycomb ceramic membrane filtering element

A honeycomb ceramic and membrane filtration technology, which is applied in the field of membrane separation, can solve the problems of many honeycomb ceramic membrane preparation processes, low yield of honeycomb ceramic membrane, and increase the complexity of the preparation process, so as to avoid the reduction of the membrane area per unit volume and the structure The effect of simplifying the model and reducing the possibility of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

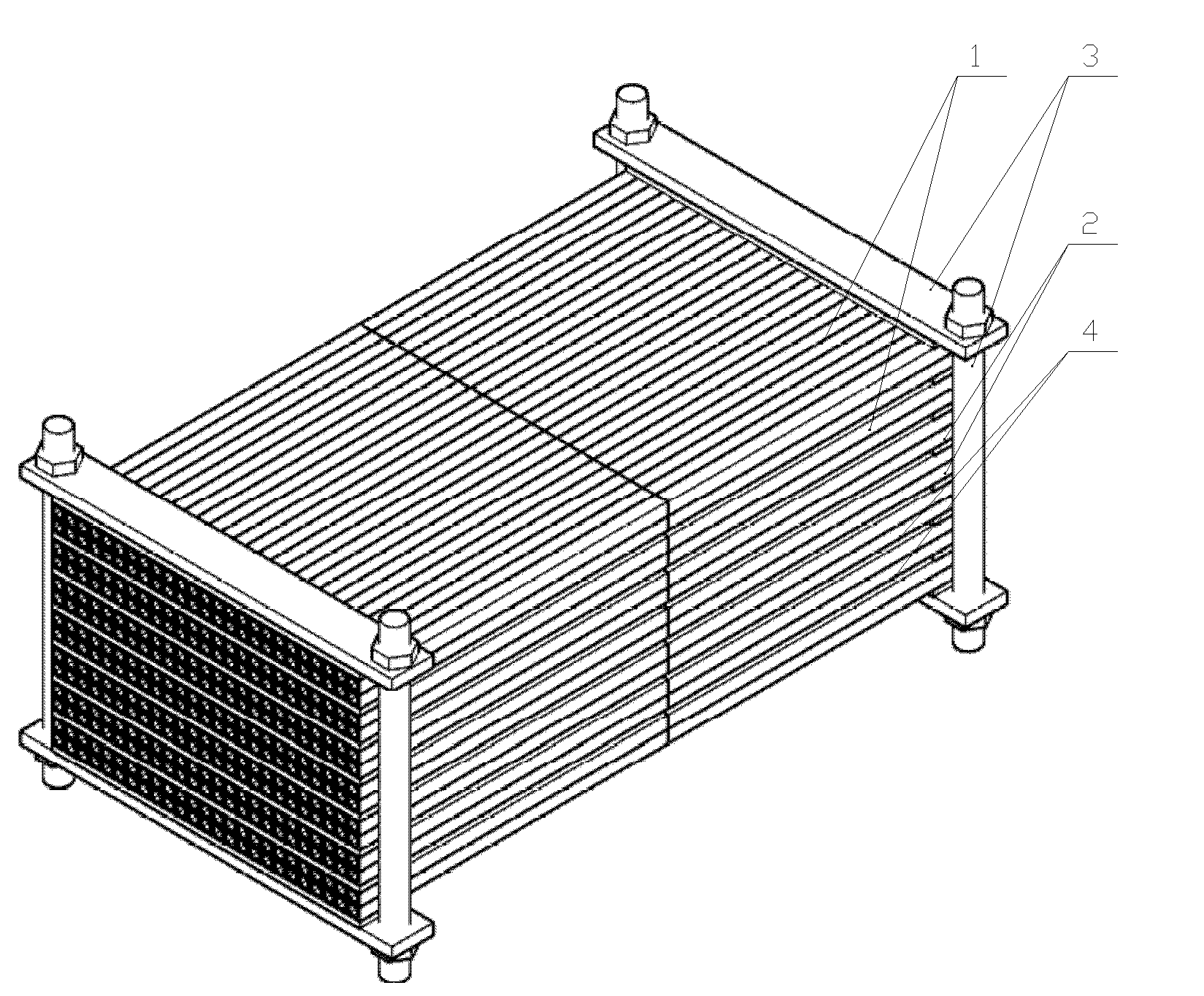

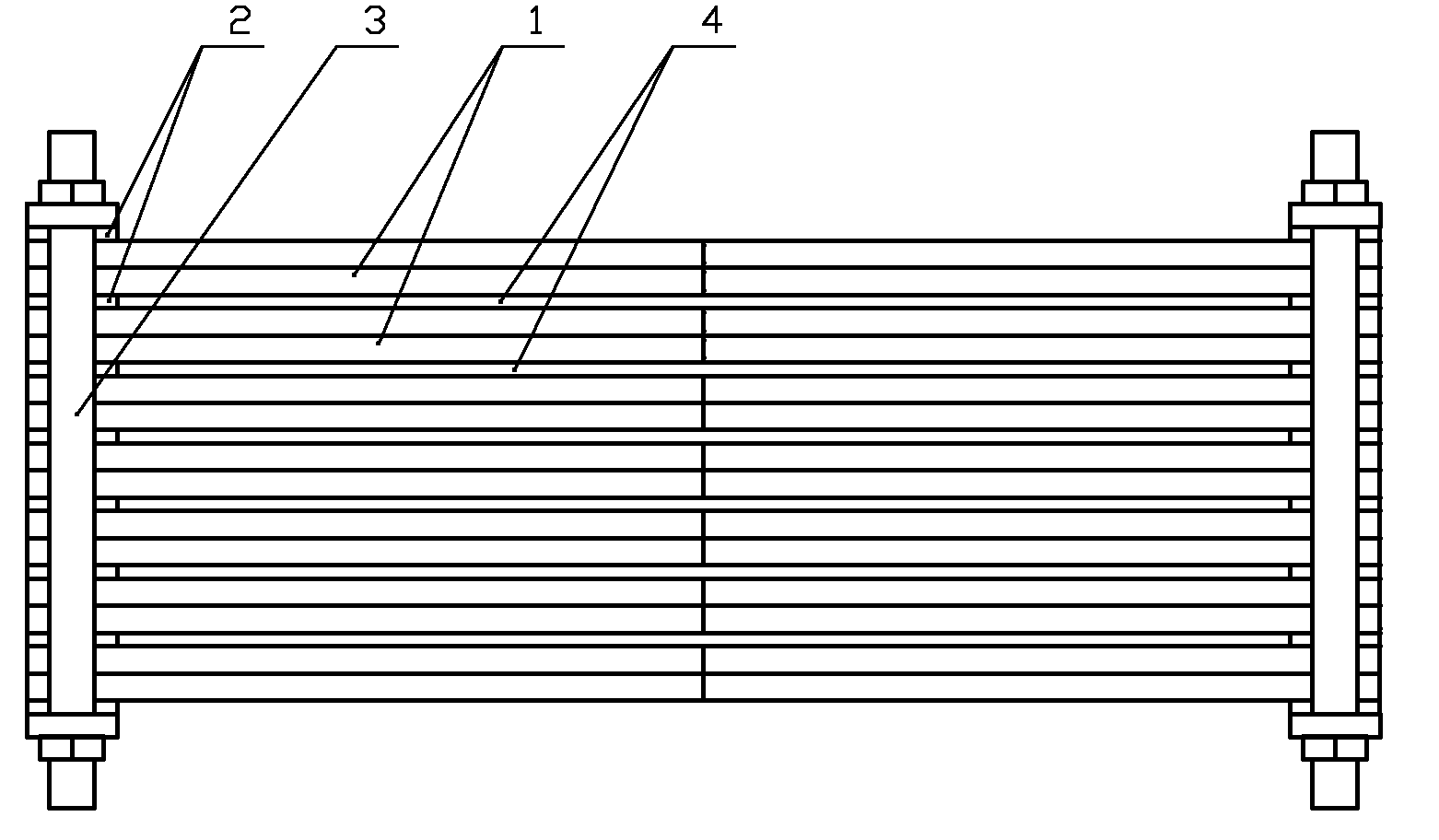

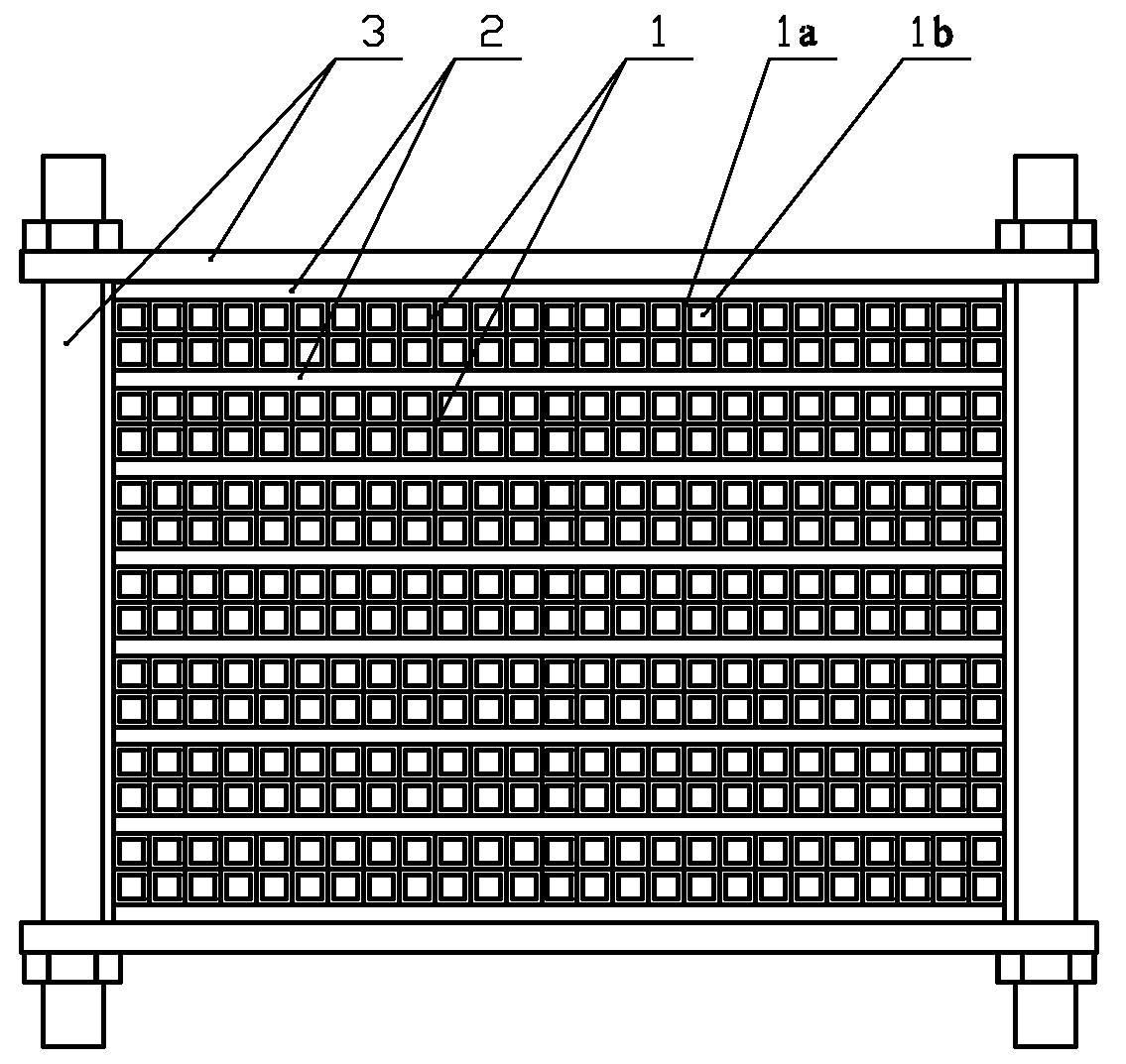

[0031] Figure 1 ~ Figure 4 Shown is one of the embodiments of the combined honeycomb ceramic membrane filter element of the present invention, as figure 1 and figure 2 As shown, it includes a honeycomb ceramic membrane unit 1, a support 2 and a fastener 3 composed of a honeycomb ceramic support 1a and a filter channel 1b.

[0032] Wherein, the honeycomb ceramic support body 1a is flat, and the axis of the filter channel 1b is parallel to the plate surface of the honeycomb ceramic support body 1a, and arranged side by side in the honeycomb ceramic support body 1a to form a honeycomb ceramic membrane monomer 1. Such as image 3 and Figure 4 As shown, the cross-sectional shape of the honeycomb ceramic membrane unit 1 perpendicular to the axis of the filter channel 1b is rectangular. The filter channel 1b adopts double rows of channels, the cross-sectional shape of the channel is square, and the wall thickness W1 between the filter channel 1b and the outer surface of the ho...

Embodiment 2

[0037] Figure 5 and Figure 6 Shown is the second embodiment of the combined honeycomb ceramic membrane filter element of the present invention, which differs from embodiment one in that: as Figure 5 As shown, the cross-sectional shape of the honeycomb ceramic membrane monomer 1 perpendicular to the axis of the filter channel 1b is an arc-containing trapezoid, which is stacked and combined at intervals to form a cylinder (see Figure 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com