A laminated composite material used for magnetoelectricity storage unit

A composite material and memory technology, which is applied in the field of composite materials for laminated magnetoelectric memory, can solve the problems of less research on inverse magnetoelectric effect, limited application of piezoelectric materials, etc., and achieves low power consumption, simple structure, Easy-to-tune effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

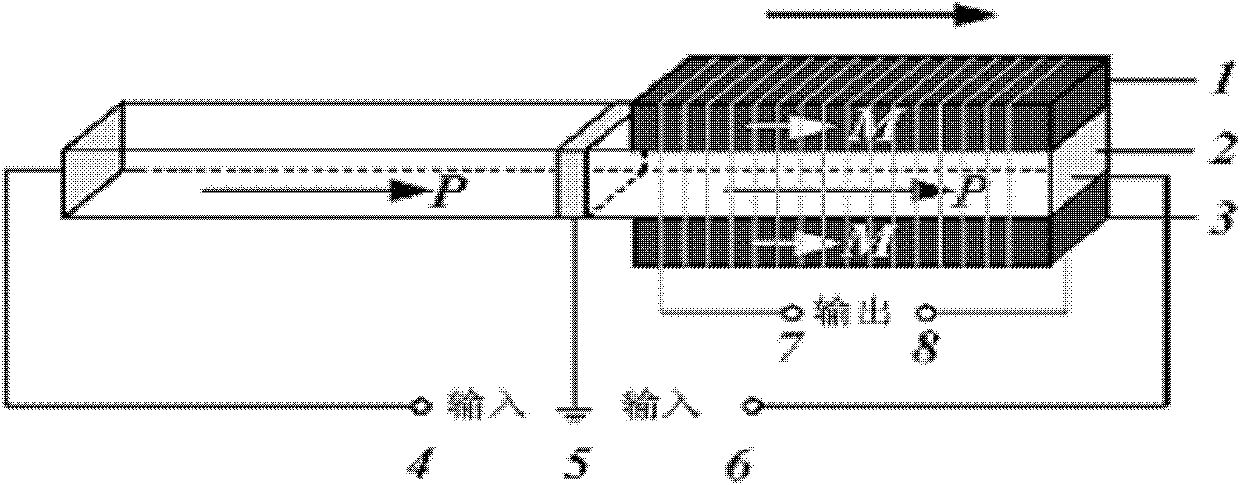

[0026] Anti-magnetoelectric composite material structure such as figure 1 As shown, the Bridgman method is used to grow a lead magnesium niobate-lead titanate PMN-PT single crystal with a composition of 0.28 direction, and the piezoelectric material 2 is produced. Magnetostrictive material 1 and magnetostrictive material 3 are made of terbium dysprosium iron Terfenol-D alloy. The size of lead magnesium niobate-lead titanate PMN-PT is 16×2×2mm 3 , the size of Terfeno1-D is 6×2×2mm 3 . A voltage input terminal 4 , a common ground terminal 5 and a voltage input terminal 6 are drawn from the piezoelectric material 2 . The piezoelectric material 2 also leads to an induced voltage output terminal 7 and an induced voltage output terminal 8 . The magnetostrictive material 1, the piezoelectric material 2 and the magnetostrictive material 3 are bonded with non-conductive epoxy resin, so that the upper and lower layers of the magnetostrictive material and the piezoelectric material h...

Embodiment 2

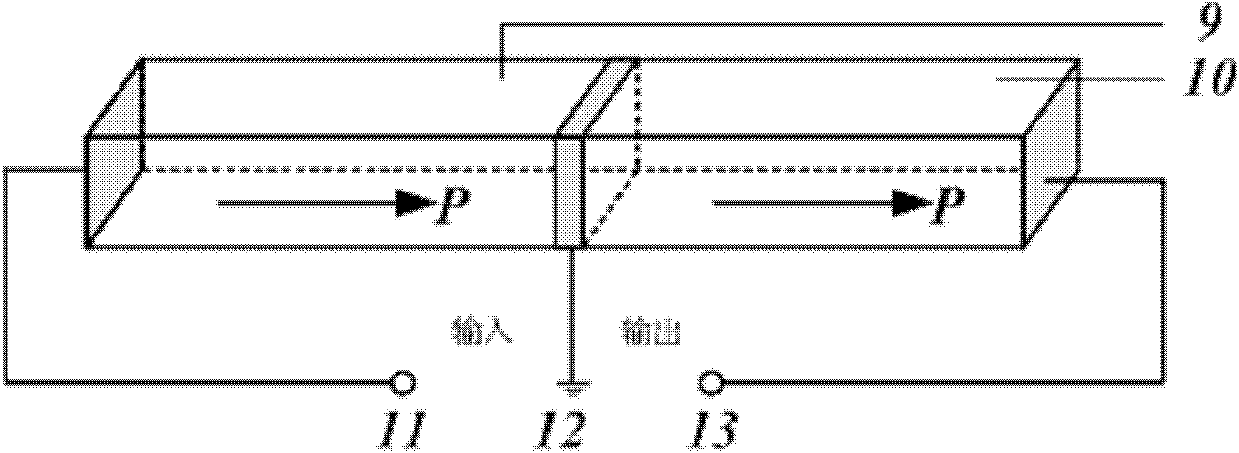

[0028] Fabricate piezoelectric materials with amplifying capabilities. Such as figure 2 As shown: the left half is the driving part 9, and the right half is the output part 10, both of which are polarized along the length direction, such as figure 2 As indicated by the middle arrow, the electrode positions are as shown in Figure 11, electrode 12 and electrode 13. Electrode 11 and electrode 13 are full electrodes, and the width of electrode 12 is 1 mm.

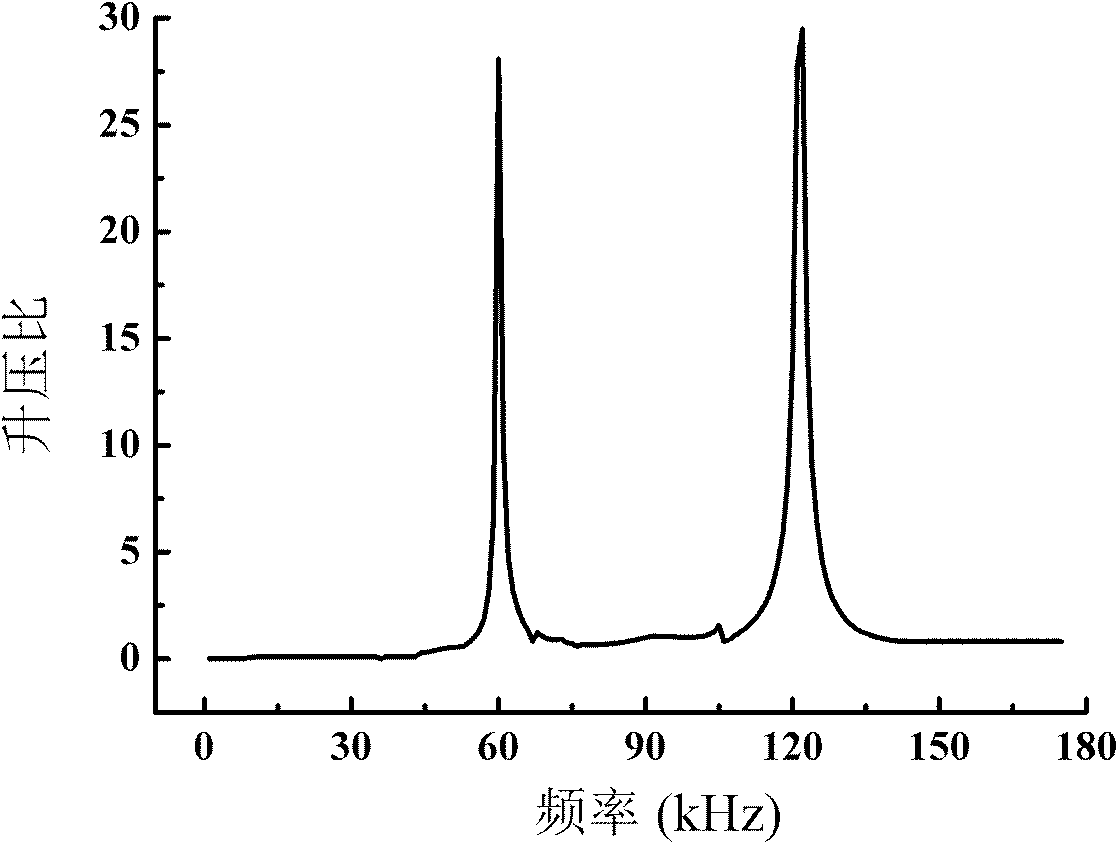

[0029] When testing the boost ratio curve of the piezoelectric material with amplifying function, the signal generator is connected to the input terminal electrode 11 and the ground terminal electrode 12 , and the oscilloscope is connected to the output terminal electrode 13 and the ground terminal electrode 12 . Test results such as image 3 As shown, at around 60kHz and 120kHz, the step-up ratio can reach 30 times.

Embodiment 3

[0031] Test the inverse magnetoelectric coefficient of composite materials:

[0032] In order to effectively transmit the strain energy of the piezoelectric material to the magnetostrictive material, Terfenol-D with a similar length is selected and glued to the piezoelectric material 2. The size of Terfenol-D is 6×2×2mm 3 . After the magnetostrictive material 1, piezoelectric material 2 and magnetostrictive material 3 of embodiment 1 are combined, test its inverse magnetoelectric coefficient, the input magnetic field amplitude is 1Oe, and the frequency range is 1-175kHz, the results show that, Under the optimal bias magnetic field of 800Oe, when an electric signal is applied to the voltage input terminal 4, the inverse magnetoelectric coefficient after preamplification in the resonant state can reach up to 0.54G / V.

[0033] The composite material for the laminated magnetoelectric memory of the invention can provide multi-terminal input, and the output of the reverse magnetoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com